Method for calculating production capability of airplane assembly line workers

A production capacity, assembly line technology, applied in computing, instrumentation, data processing applications, etc., can solve problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

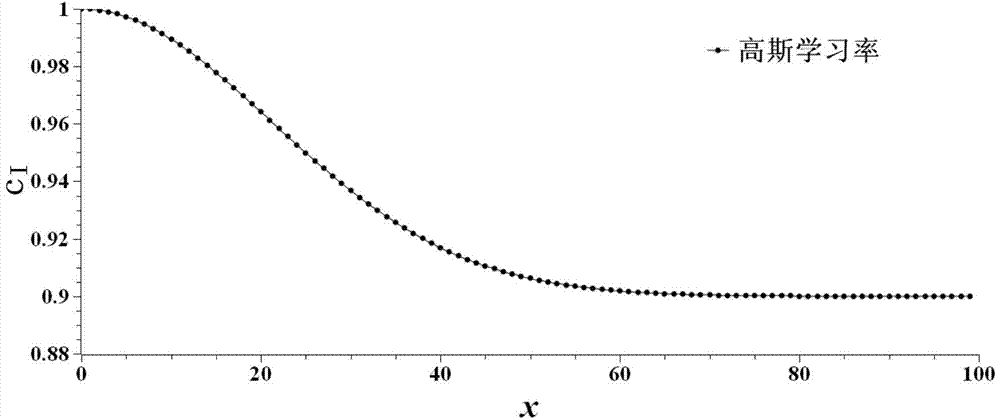

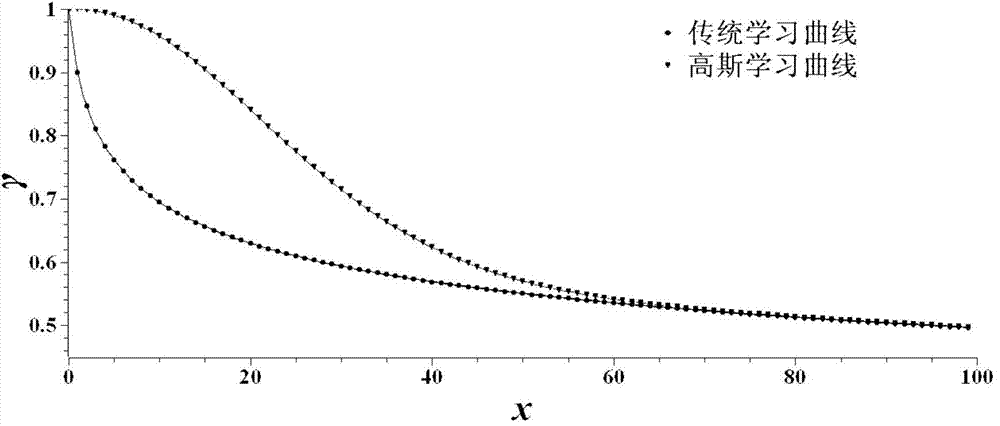

[0037] refer to Figure 1-4 . The specific steps of the calculation method for the production capacity of aircraft assembly line personnel in the present invention are as follows.

[0038] This example is to solve the personnel production capacity of the rear fuselage assembly line of a certain type of aircraft. The assembly line is mainly composed of 5 assembly stations and a total of 86 processes. people.

[0039] (a) According to the structural characteristics of the rear fuselage product group components and the process characteristics of the assembly process, the assembly operation is decomposed into the bottom assembly operation elements. After statistical analysis, the types of assembly operation elements are divided according to the types of processes k=1,2,...,N ij , and concluded that the main processes of rear fuselage assembly operations include: assembly preparation, pre-positioning / positioning of parts, drilling, riveting, cleaning and sealing, testing and remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com