Calibration device, calibration method and monitoring system

A technology of calibration device and calibration method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unachievable calibration, inaccurate calibration, low work efficiency, etc., and achieve the goal of not easy to deviate, high precision, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

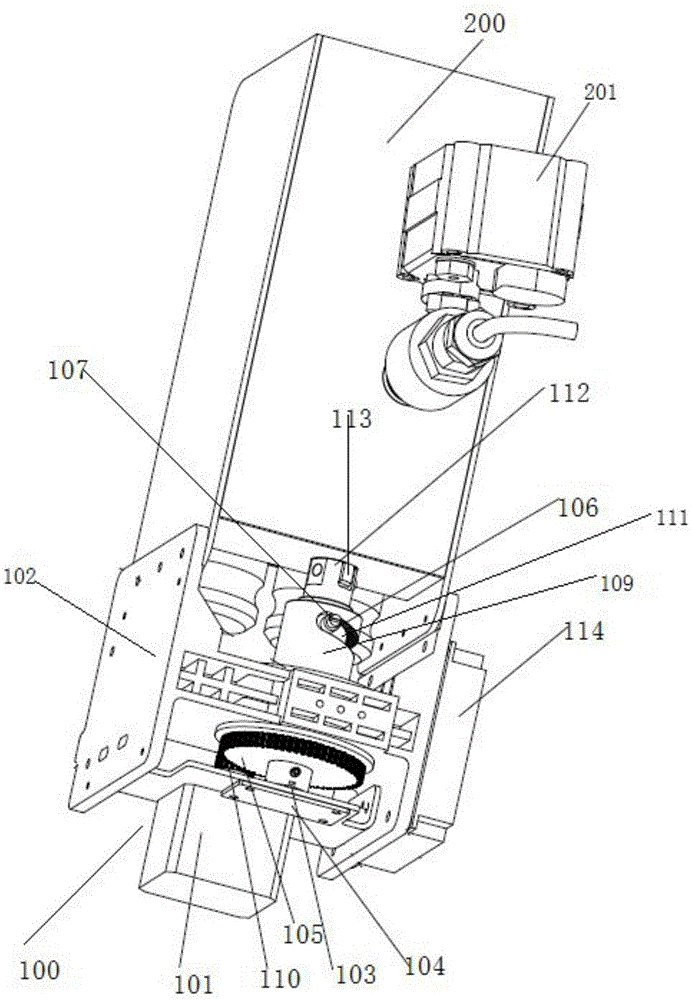

[0051] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides a calibration device 100, including: a motor 101, an assembly bracket 102, a magnet 103, an encoder 104, a large gear 105, a pinion 110, a transmission shaft 109, a chute 106, and a connector 111, slide block 107 and control panel 114,

[0052]The motor 101 and the encoder 104 are fixed on the assembly bracket 102, the motor 101 is connected to the axis of the pinion 110, the pinion 110 meshes with the teeth of the bull gear 105 to form a linkage gear, and the transmission shaft 109 passes through the axle of the bull gear 105 And be fixedly connected with big gear. Transmission shaft 109 is closed at one end and open at one end. The large gear 105 is located at the closed end of the transmission shaft 109. The magnet 103 is fixed at the shaft center of the closed end of the transmission shaft 109. The transmission shaft 109 has a chute 106 near the open end. The device 111 extend...

Embodiment 2

[0068] Such as figure 1 , figure 2 As shown, the embodiment of the present invention also provides a monitoring system, including a calibration device 100 and a monitoring instrument 200, the calibration device 100 and the monitoring instrument 200 are connected through the connector 111, and the calibration device 100 can realize the monitoring instrument 200 is automatically calibrated.

[0069] The calibration device 100 in the embodiment of the present invention is the same as the calibration device provided in the first embodiment, and will not be repeated here.

[0070] In one embodiment of the present invention, the part of the monitoring instrument 200 connected with the calibration device 100 is provided with a standard scatter plate knob 113, by rotating and pushing the standard scatter plate knob 113, the standard scatter plate can be moved to the monitoring position or built-in a specific Location.

[0071] In one embodiment of the present invention, the monito...

Embodiment 3

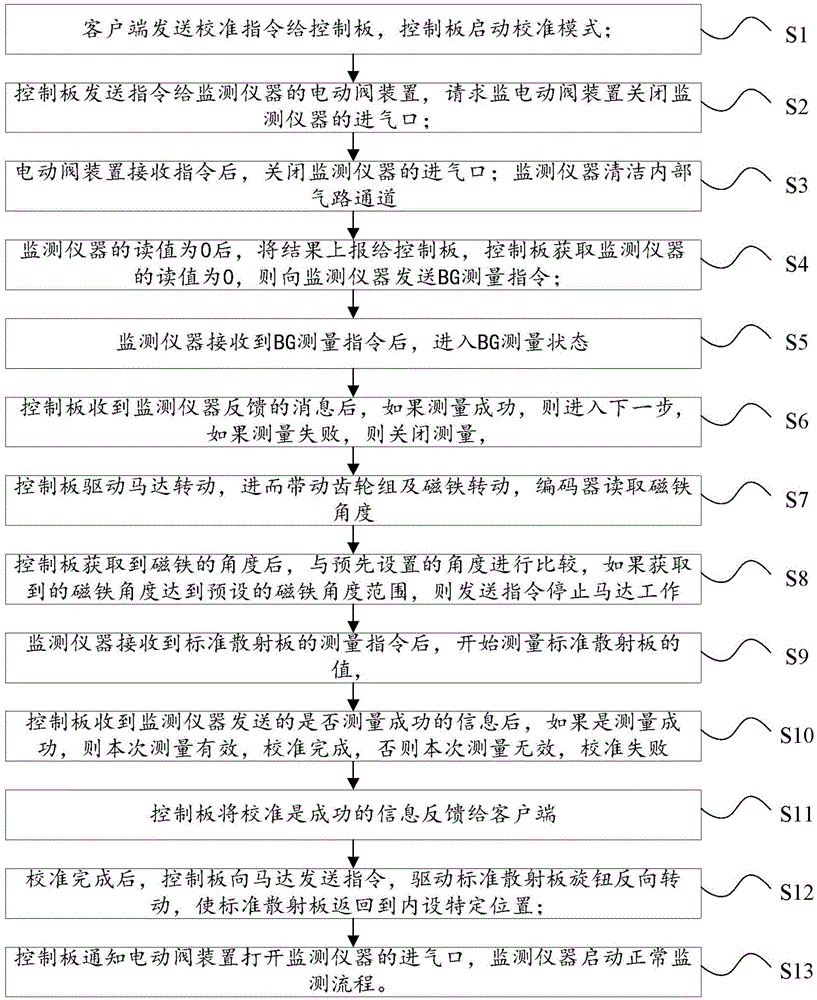

[0076] An embodiment of the present invention provides a calibration method, using the calibration device shown in Embodiment 1, including the following steps:

[0077] S1. The client sends a calibration command to the control board, and the control board starts the calibration mode;

[0078] The client can be the background management system of the monitoring system, and can regularly or periodically calibrate the monitoring instrument. When calibration is required, a calibration command is sent to the control board to start the calibration mode. In another embodiment of the present invention, the client It can also be referred to as a host computer, where the host computer or client can be a computer or other smart device, which can be used to send control signals to the control board and receive monitoring parameters returned by the control board.

[0079] S2. The control board sends an instruction to the electric valve of the monitoring instrument, requesting the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com