High-sensitivity resonant MEMS vector hydrophone structure

A vector hydrophone, high-sensitivity technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as poor anti-interference ability and low sensitivity, and achieve strong anti-interference ability, high sensitivity, and solution. The effect of poor anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

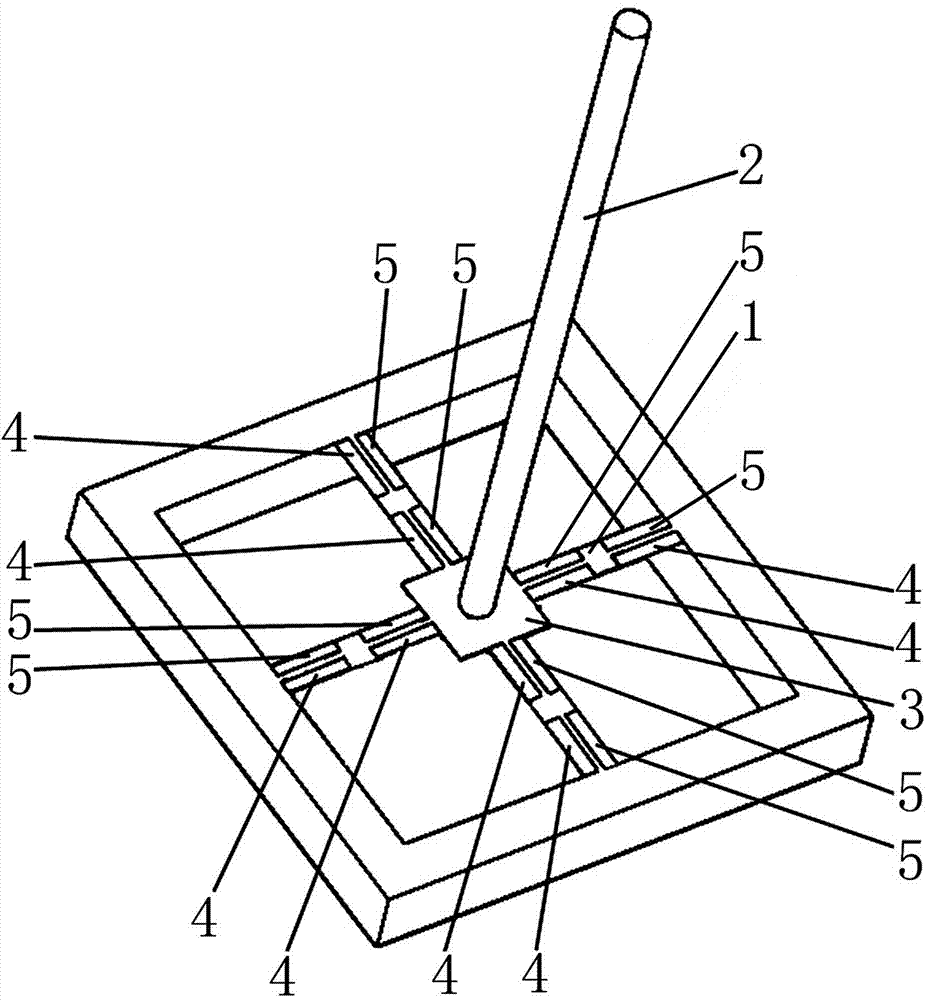

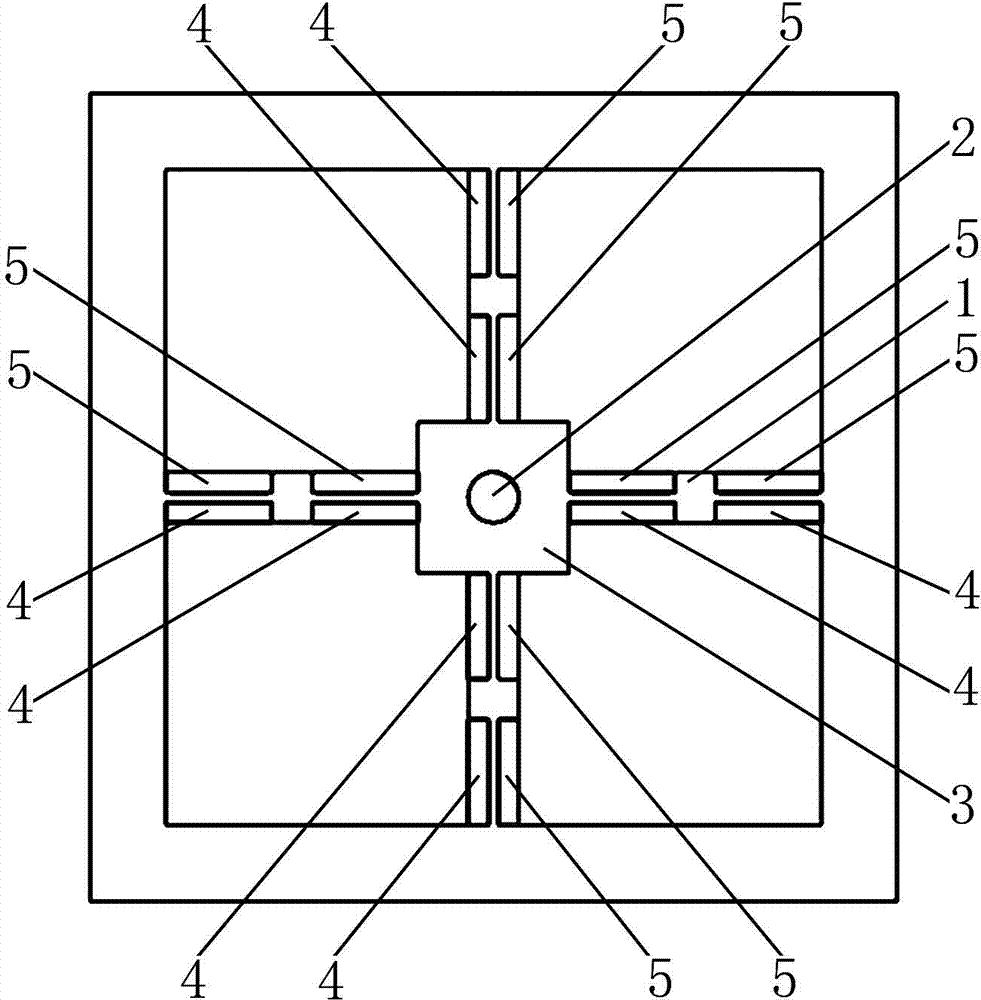

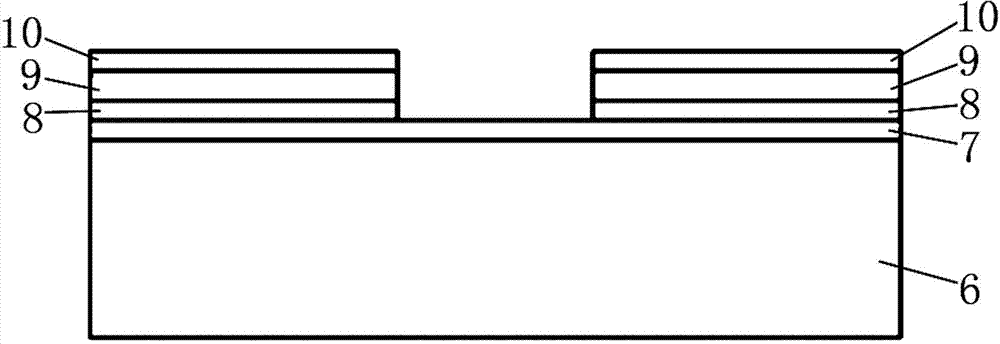

[0014] A high-sensitivity resonant MEMS vector hydrophone structure, including a four-beam arm silicon microstructure 1, a micro-column body 2, a central connector 3, a driving electrode 4, and a detection electrode 5;

[0015] Wherein, the silicon microstructure 1 with four beam arms and the central connecting body 3 are located on the same plane; the lower end of the miniature columnar body 2 is vertically fixed on the center of the upper surface of the central connecting body 3; the number of driving electrodes 4 and the number of detecting electrodes 5 are eight;

[0016] The first drive electrode 4 is laid on the left front part of the upper surface of the front beam arm of the four-beam silicon microstructure 1; the second drive electrode 4 is laid on the left rear part of the upper surface of the front beam arm of the four-beam silicon microstructure 1 ; The third driving electrode 4 is laid on the upper surface left rear part of the left beam arm of the four-beam silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com