Energy-saving centralized air conditioning dehumidification system for tobacco mellowing warehouse and control method

A centralized air-conditioning and energy-saving technology, which is applied to the energy-saving centralized air-conditioning dehumidification system and control field for tobacco alcoholization warehouses, can solve the problems of inconvenient operation and maintenance, unstable power grid, damage, etc., and save the initial investment of equipment and operating costs. , convenient centralized maintenance, reasonable temperature and humidity control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

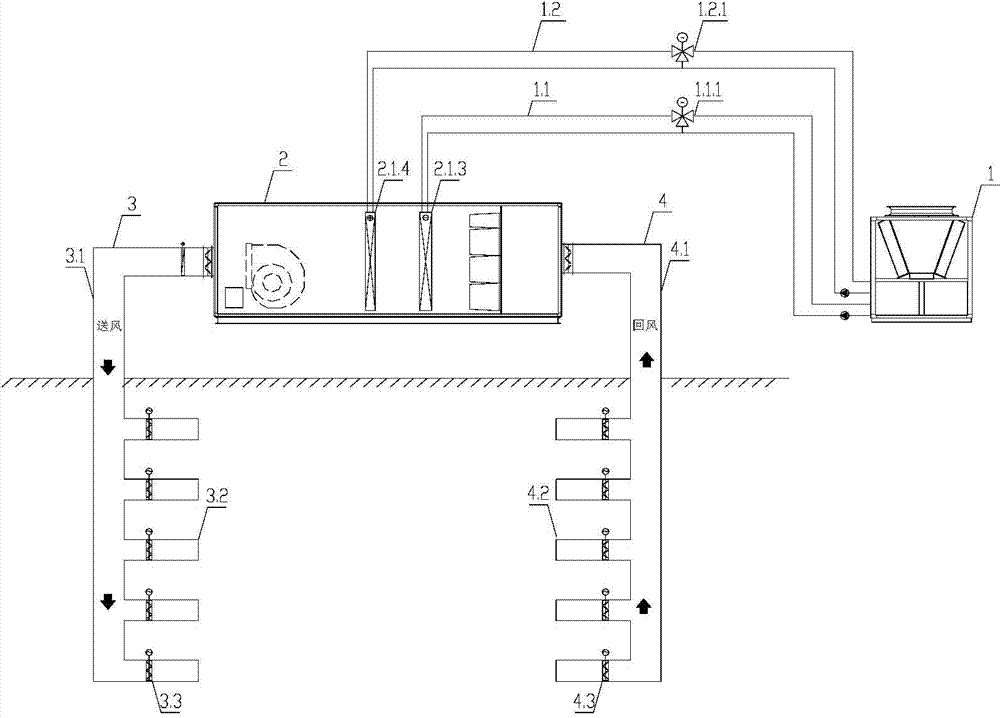

[0024] like figure 1 As shown, the energy-saving central air-conditioning dehumidification system for tobacco leaf alcoholization warehouse according to the present invention mainly consists of heat recovery type air-cooled heat pump unit 1), roof-type combined air handling unit 2, and supporting air supply duct 3 and return air The pipeline consists of 4. The heat recovery type air-cooled heat pump unit 1 and the roof-mounted combined air handling unit 2 constitute the roof-type centralized air dehumidification equipment, which is installed on the roof of the tobacco leaf warehouse or outdoors to provide air cooling and dehumidification, heating, filtering and other functions for the tobacco leaf aging environment, and automatically With cold and heat source. The air supply duct 3 and the return air duct 4 constitute the air supply and return duct system, which is used to divert and transport the air treated by the roof-type combined air handling unit 2 to the tobacco leaf s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com