A plugging compartment for multi-pulse gas generator

A gas generation and multi-pulse technology, which is applied to jet propulsion devices, rocket engine devices, intermittent injection devices, etc., can solve the problems of complex system structure, waste of control valve resources, and high production costs, and achieves simple and reliable structure. The effect of strong replacement and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

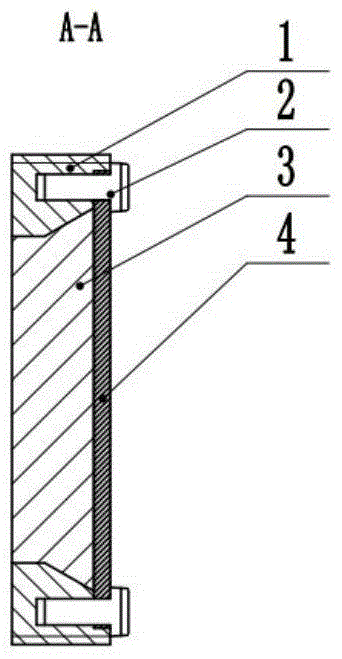

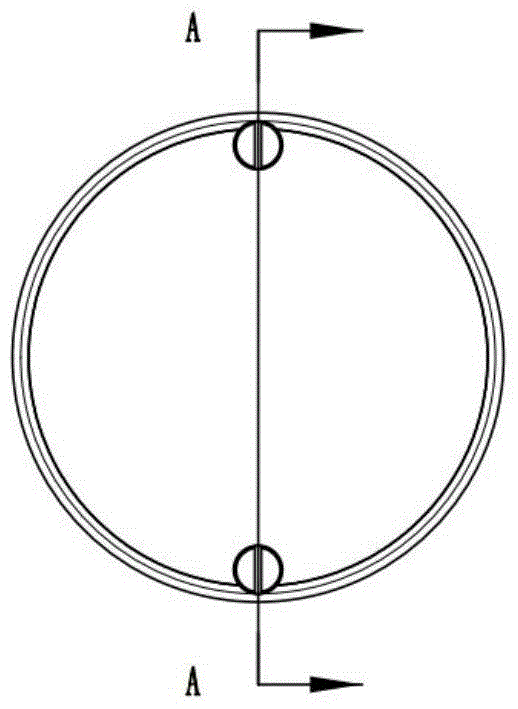

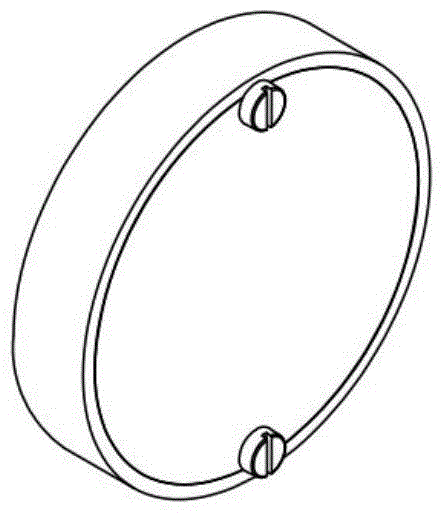

[0022] A plug-type interlayer disclosed in this embodiment for a multi-pulse gas generator includes: a mounting sleeve 1 , a connecting screw 2 , a plug 3 , and a gasket 4 .

[0023] The plug 3 is shaped like a trapezoidal cylinder in cross section, the first half of which is a cylinder, and the second half of which is a cone.

[0024] The outer surface of the installation sleeve 1 is a cylinder, the first half of the inner surface is cylindrical, and the second half is conical, which matches the shape of the plug 3 . Threaded holes are formed on the side of the mounting sleeve 1 with a larger inner hole diameter, and the threaded holes are distributed symmetrically in the circumferential direction. The outer surface of the mounting sleeve 1 is threaded.

[0025] Connection relationship: the plug 3 is placed in the installation sleeve 1; the gasket 4 is placed on the plug 3 and the installation sleeve 1; the connecting screw 2 is fixed and installed in the threaded hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com