System and method for gas purge control

一种节气门、进气歧管的技术,应用在电气控制、装料系统、发动机控制等方向,能够解决不新鲜空气系统等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

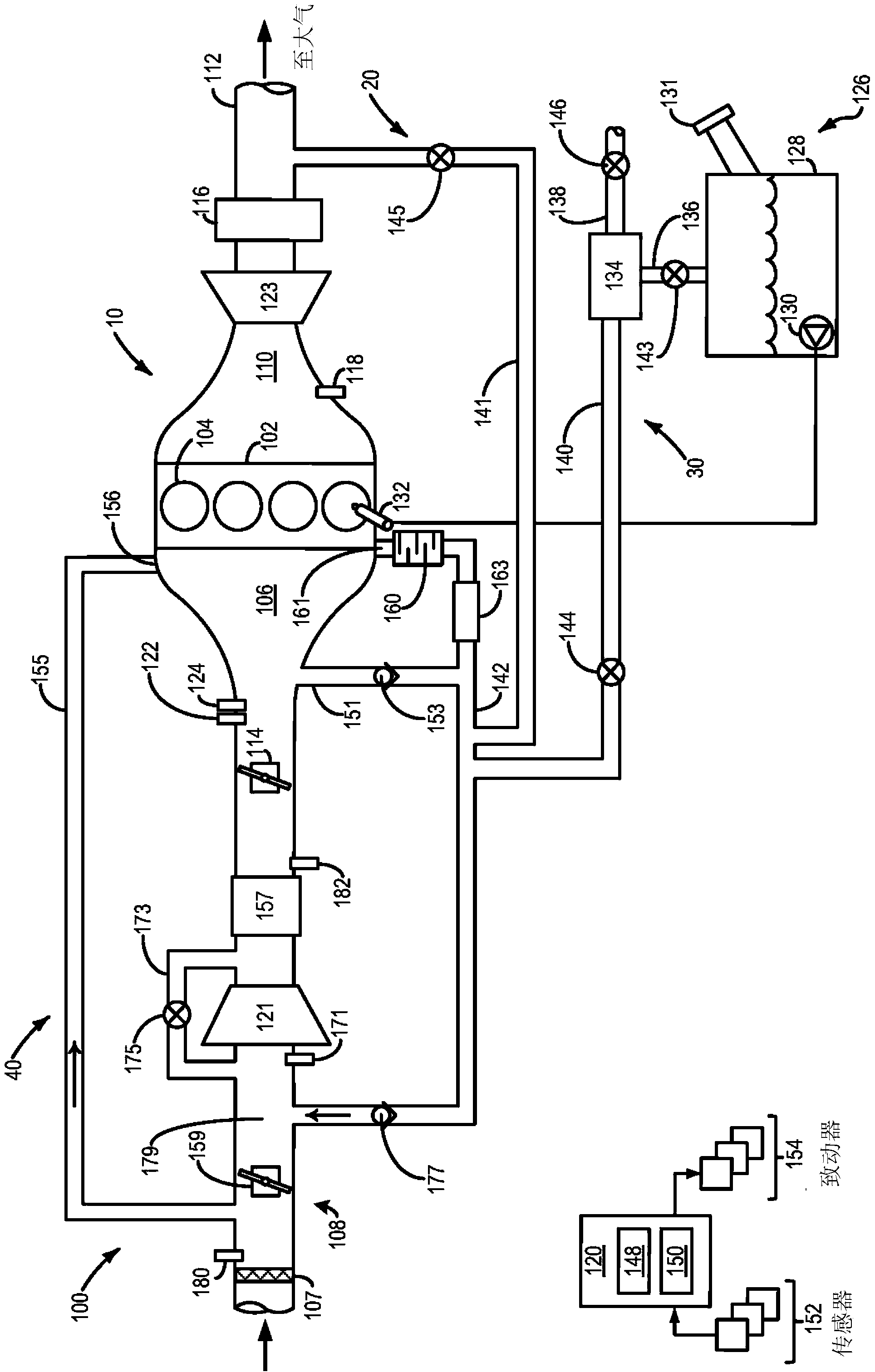

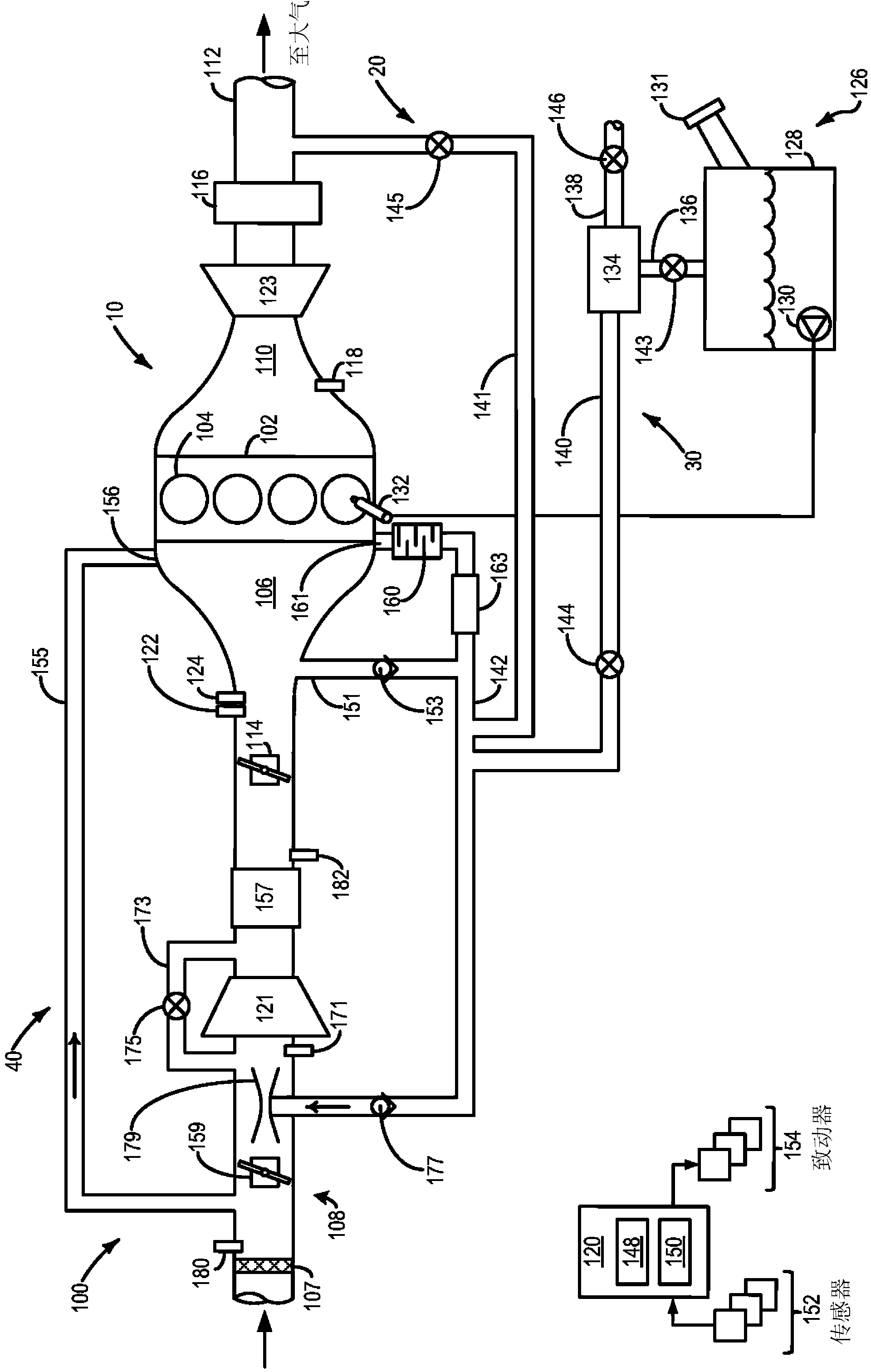

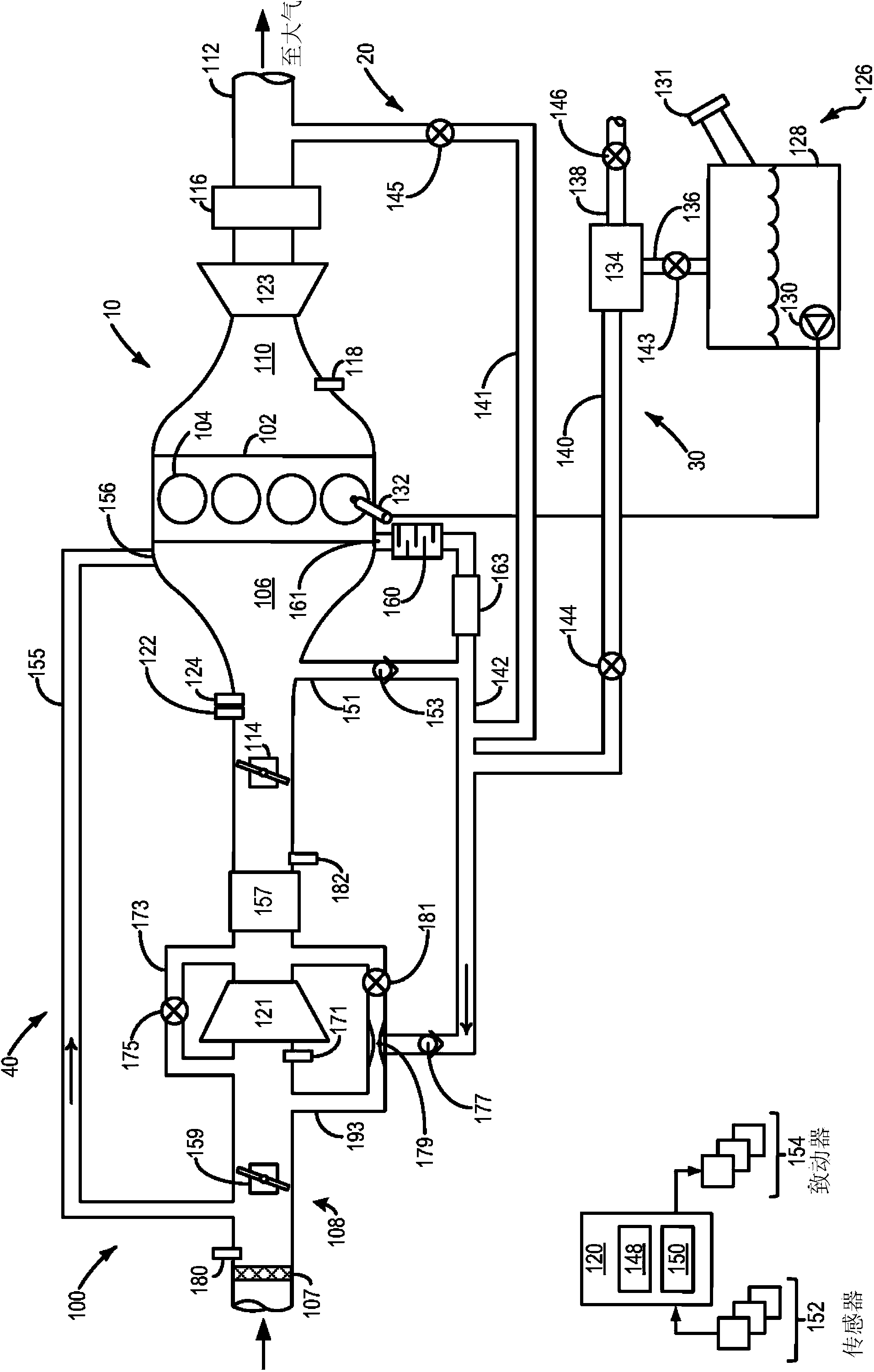

[0011] This detailed description relates to the Figure 1-4 Systems and methods for providing vacuum by one or more of a crankcase ventilation system, an emission control system, and an exhaust gas recirculation (EGR) system in an engine system shown in . like Figure 1-4 As shown, a vacuum source such as an ejector or a venturi can be included in the intake port of the engine downstream of the compressor pre-throttle and upstream of the intake throttle, and can be used to provide a vacuum proportional to the flow rate of the engine intake air. proportional vacuum. like Figure 5 As shown, the vacuum generated by the vacuum source in the engine intake may be used to drive consistent flow through crankcase ventilation systems, emission control systems, and exhaust gas recirculation (EGR) systems included in the engine system.

[0012] figure 1 An example of an engine system 100 according to an embodiment of the disclosure is schematically shown. Engine system 100 may be inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com