Gas turbine rotor positioning device

A gas turbine and rotor technology, applied in safety devices, blade support components, engine components, etc., can solve the problem that oil is not the actuating medium and it is difficult to control the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

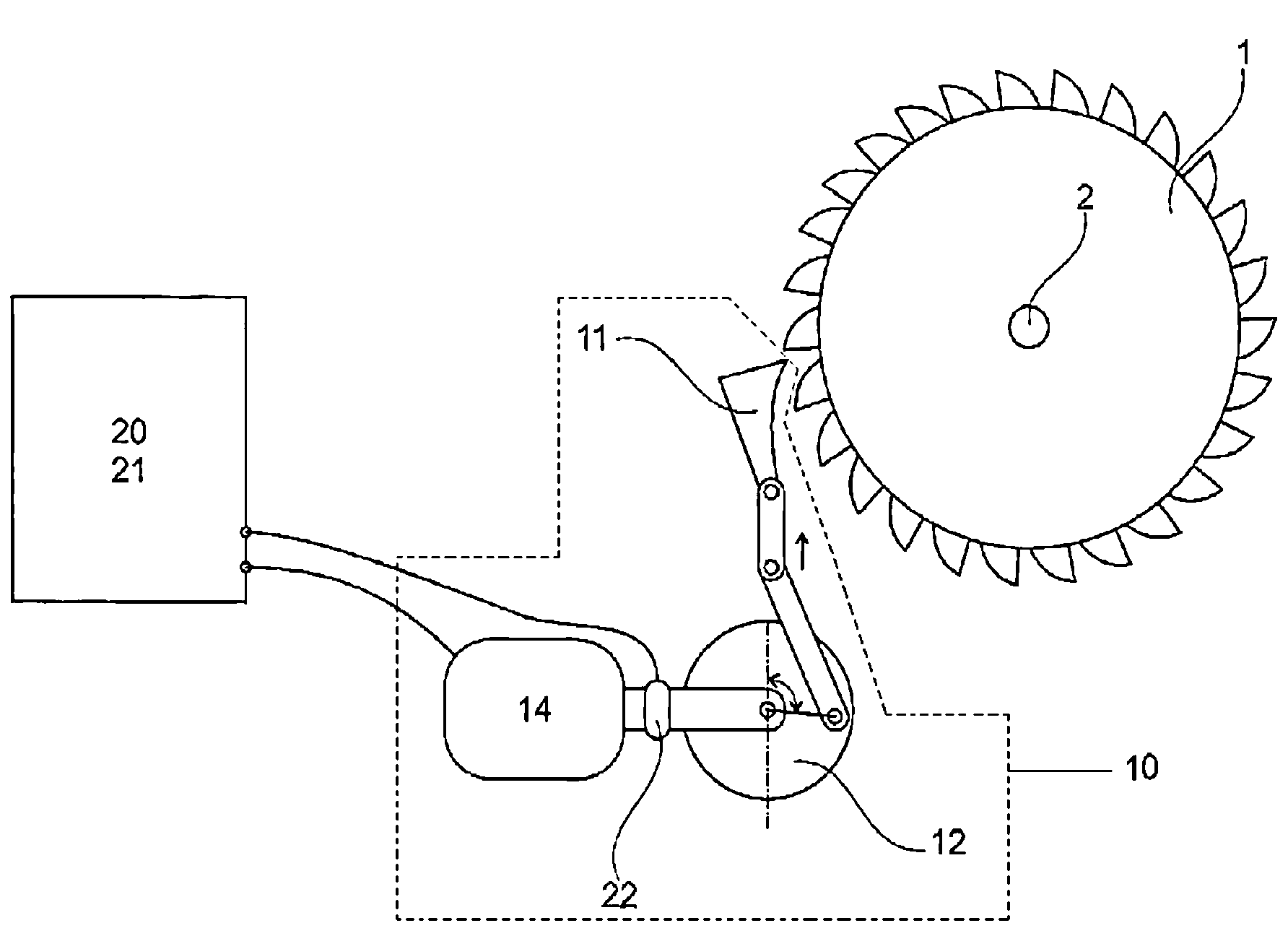

[0017] The invention relates to a device for positioning a gas turbine rotor 2 in a precise manner. The device comprises a piston rod 11 which linearly moves its ratchet 1 which moves the gas turbine rotor 2 . The drive mechanism 10 comprises an eccentric 12 and a drive device (preferably a synchronous motor 14). The piston rod 11 is moved by an eccentric 12 connected to a synchronous motor 14 .

[0018] The synchronous motor 14 of the drive mechanism 10 allows precise control of its angular position by means of an incremental counter.

[0019] The frequency converter 21 can vary the rotational speed of the synchronous motor 14, which determines the speed and position of the piston rod 11, and the output torque of the synchronous motor, which allows the definition of the applied linear force.

[0020] The conversion of the triangular trajectory from the rotational movement of the synchronous motor 14 to the linear movement of the piston rod 11 is performed by the motion cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com