Multifunctional environment-friendly and coating-saving wall painting machine

A wall brushing machine, multi-functional technology, applied in the direction of construction, building construction, etc., can solve problems such as environmental pollution, affecting the quality of the wall, heavy workload, etc., to achieve the effect of reducing environmental pollution, reducing decoration costs, and liberating labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

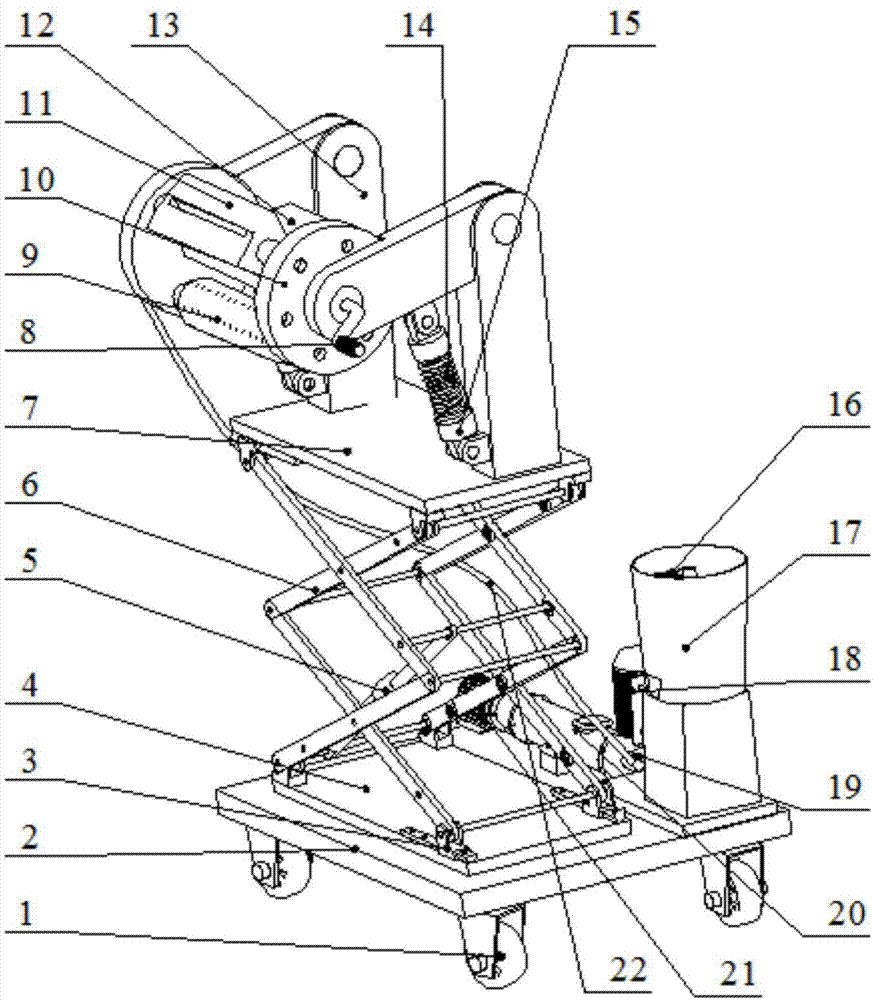

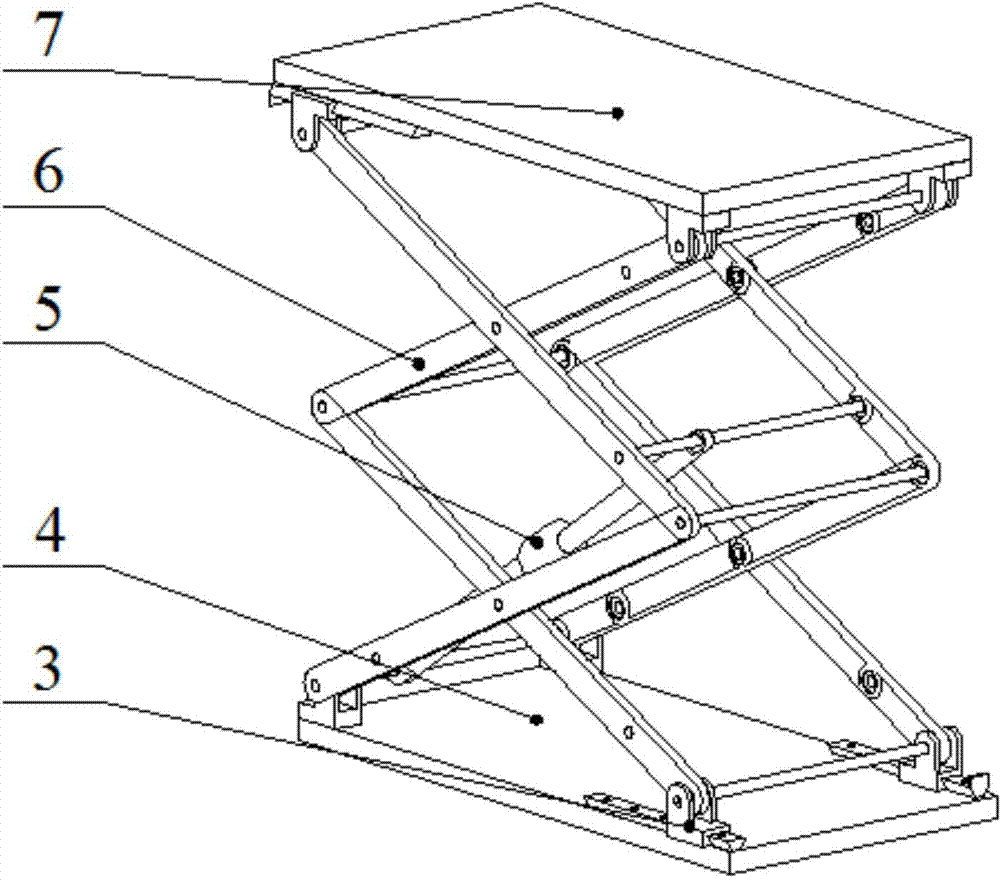

[0027] Such as Figure 1-Figure 5 As shown, the multifunctional environmental-friendly material-saving wall brushing machine of the present invention is a trolley structure as a whole, including a base 2, a movement module, a wall brushing module, a feeding module 20 and a stirring module. The motion module includes a lifting mechanism installed on the base 2, and the lifting mechanism drives the wall painting module to move vertically.

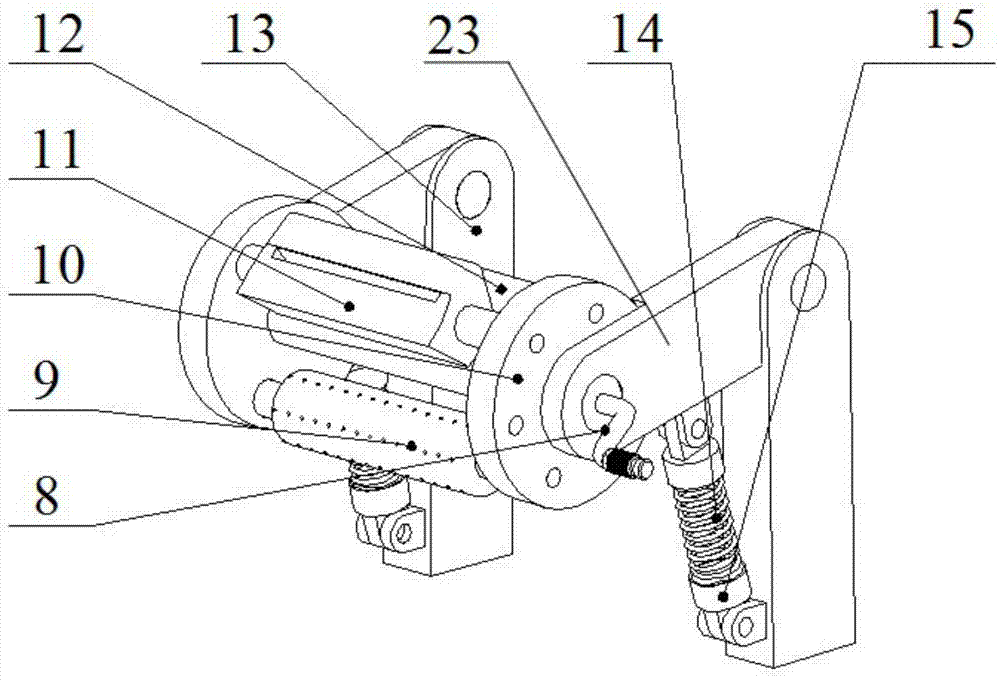

[0028] The wall brushing module includes a roller brush 9 , a greasy scraper 11 , a grinding disc 12 and a rotary positioning mechanism 10 , and the rotary positioning mechanism 10 includes a turntable 1002 , a positioning pin 1004 and a return spring 1005 . The top of the lifting mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com