Weft drawing device of air jet loom

An air-jet loom and weft drawing technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of easy formation of thread clusters, unclean drainage, and low degree of automation, so as to avoid clogging of waste yarn and yarn discharge channel Unobstructed and high loom efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

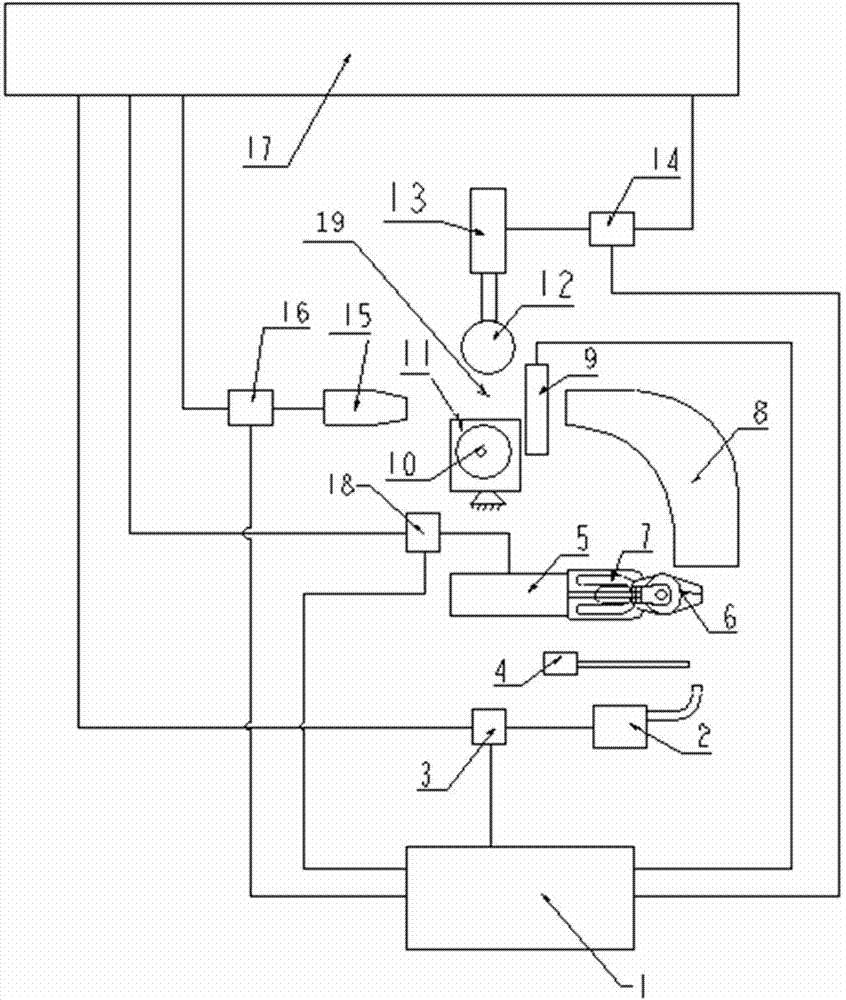

[0015] Such as figure 1 As shown, a weft drawing device of an air-jet loom, which uses the guided airflow to drive the waste yarn to fly and the rotation of the driving wheel and the pressure wheel to extract the waste yarn, including a controller 1, a guide nozzle mechanism, a scissors mechanism, and an air flow guide Tube 8, driven pressure wheel mechanism, driving wheel mechanism, yarn detection sensor 9, waste yarn suction port structure, air source 17, the guide nozzle mechanism includes guide nozzle 2, and the scissors mechanism includes scissors cylinder 5, scissors 6 , guide frame, described scissors cylinder 5 is connected with guide frame, described guide frame is provided with scissors chute 7, two handles of the rear portion of described scissors cooperate with guide chute 7 of guide frame, scissors 6 The linear reciprocating motion in the guide chute 7, and under the guidance of the two guide chutes of the scissors chute 7, the scissors 6 perform opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com