A concrete glue reducer

A glue reducer and concrete technology, which is applied in the field of chemical building materials, can solve the problems of negative impact on concrete durability, uneven technical development level, and nowhere to put solid waste, etc., to improve initial flow performance and improve hydration degree, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] 1. The components of ZWL-I glue reducer are as follows

[0011] Sodium aminotrimethylene phosphonate 1.2 Kg

[0012] Resorcinol 3.5 Kg

[0013] Triisopropanolamine 7.5 Kg

[0014] N-Methyldiethanolamine 2.8 Kg

[0015] Water (tap water) 85.0 Kg.

[0016] Accurately weigh sodium aminotrimethylene phosphonate, resorcinol, triisopropanolamine and N-methyldiethanolamine, then add to water at 25°C to 35°C and stir until completely dissolved.

[0017] 2. Concrete test material

[0018] Cement: Zhonglida P.O 42.5

[0019] Fly ash: Jiaxing Class II fly ash

[0020] River sand: Ganjiang sand, the fineness modulus is 2.7, the mud content is 1.8%, and the mud content is O

[0021] Stones: Xinkaiyuan stones, 5-20mm continuous graded stones.

[0022] Water reducer: ZWL-A-IX polycarboxylate high performance water reducer and ZWL-A-H naphthalene water reducer.

[0023] Glue reducer: ZWL-I type glue reducer.

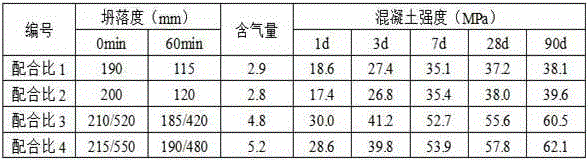

[0024] Concrete mix ratio:

[0025]

[0026] Specific concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com