Low-Reynolds-number airfoil section with multi-seam synergetic jet flow control and control method

A technology of synergistic jet flow and low Reynolds number, applied in the direction of wings, heat reduction structures, aircraft parts, etc., can solve problems such as unseen solutions, avoid the design of ventilation pipelines, reduce the sliding distance, and save fuel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

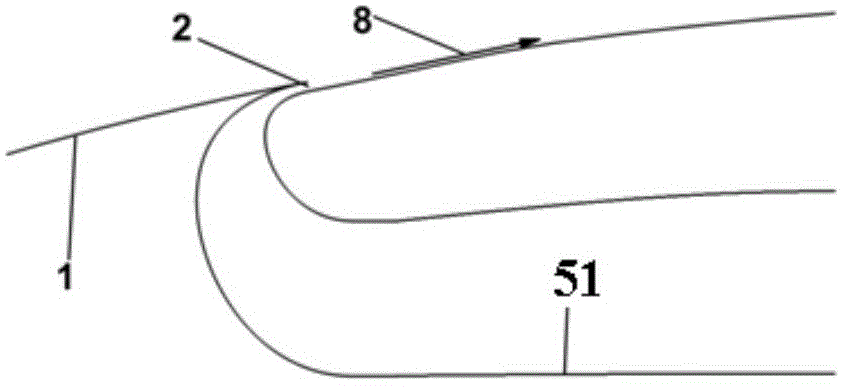

[0028] The present invention provides a low Reynolds number airfoil with multi-slot cooperative jet control, such as figure 1 As shown, it is a cross-sectional view of the airfoil, and the jet port 2 is set on the leading edge of the upper surface of the airfoil 1, see figure 2 , is a partial enlarged view of the air jet, and an air suction area 3 formed by a plurality of neatly arranged air suction microholes 10 is set on the rear edge of the upper surface of the airfoil 1; see image 3 , is a schematic diagram of micropore layout in the suction area; as a preferred method, the air injection port 2 is set at 15% to 20% of the chord line, and the height of the air injection port 2 is 3% to 5% of the chord length; the air suction area 3 is arranged At the position of 40% to 60% of the chord line, the range of the entire suction area accounts for 20% of the chord length; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com