Hot press for new-type wall material production line

A technology for wall materials and production lines, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor thermal insulation and pressure retention performance of plates, inability to adjust the thickness of hot pressing, uneven temperature distribution of hot plates, etc., to achieve adjustable spacing and reduce installation. And the effect of equipment maintenance difficulty and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some modifications and improvements can also be made, and these should also be regarded as belonging to the present invention. protection scope of the invention.

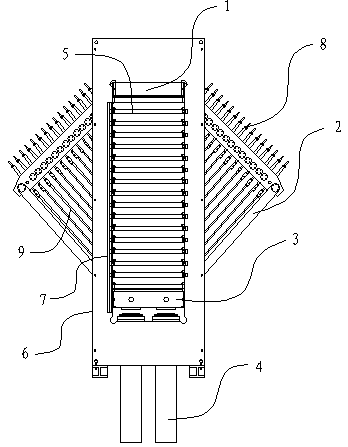

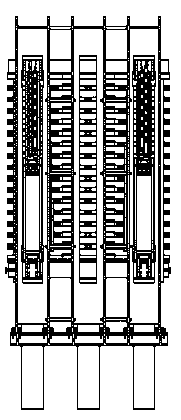

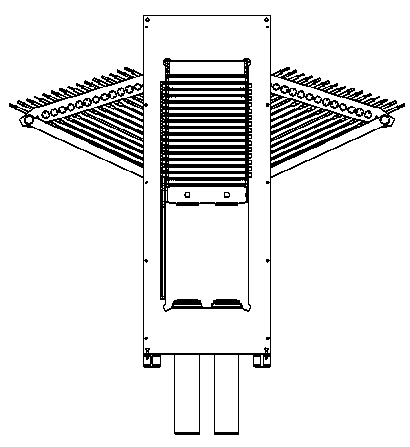

[0022] Such as figure 1 , figure 2 As shown, the present invention uses six oil cylinders 4 as the power mechanism, and the space between the hot platens 5 is equalized by the limit block during standby. . Load the templates to be pressed into the hot press for the new wall material production line, and meet the needs of thickness adjustment by replacing or adjusting the contour blocks when producing plates of different thicknesses. After the formwork is assembled, the automatic starting program oil cylinder 4 begins to work, such as image 3 , Figure 4 As shown, the oil cylinder 4 will pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com