Fixed high-speed-wire high-speed-area guide and guard device

A guide device, high-speed technology, applied in the direction of the guide/positioning/alignment device, etc., can solve the problem of the opening degree becoming larger, and achieve the effect of reducing the number of alignments, the frequency of replacing the guide wheel, and the overall structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

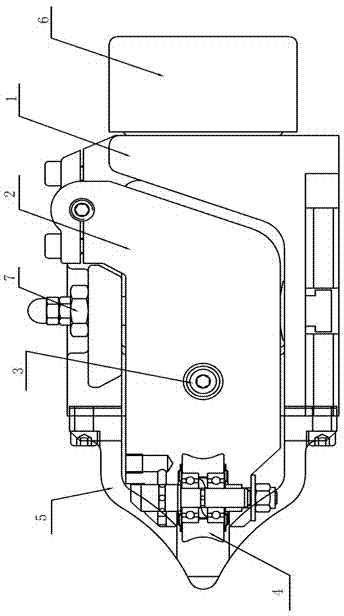

[0020] Example 1 : see figure 1 , a guide device for a fixed high-speed high-speed area, the guide device includes a box body 1, left and right support arms 2, a transition part 3 between the support arm and the box body, a guide wheel 4, a nose tip 5, a guide plate 6, a box The body 1 and the left and right support arms 2 are connected through the connecting shaft 7, the nose tip 5 is connected with the box body 1 through the hexagon socket bolt, the guide wheel 4 is connected with the support arm 2 through the connecting shaft, and the opening adjustment of the support arm is through the connection with the box body 1. When the transition part 3 is carried out, the guide is mainly to support the wire rod to enter the roll smoothly, so as to prevent the occurrence of steel stacking accidents.

Embodiment 2

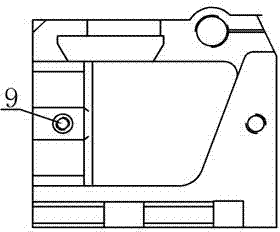

[0021] Example 2 : As an improvement of the present invention, the transition part 3 between the support arm and the box is referred to by an external threaded sleeve Figure 6 , Figure 7 and six angle nut see Figure 4 , Figure 5 composition.

Embodiment 3

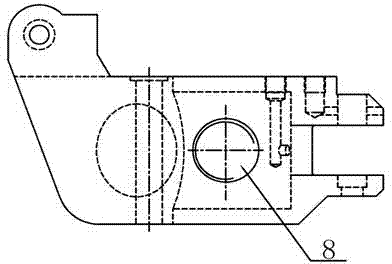

[0022] Example 3 : see figure 2 , as an improvement of the present invention, there are left-right symmetrical support arms on the guide, and the support arms are all provided with thread holes 8, the size of which is Φ28-32mm, and the threads of the externally threaded sleeve are used in conjunction with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com