An automatic seedling feeding device of a pot seedling transplanting machine for dry land vegetables

A technology for transplanting machines and vegetables, applied in the field of agricultural machinery, can solve the problems of slowness, low operation efficiency, high labor intensity, etc., and achieve the effects of high efficiency, simple structure and accurate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

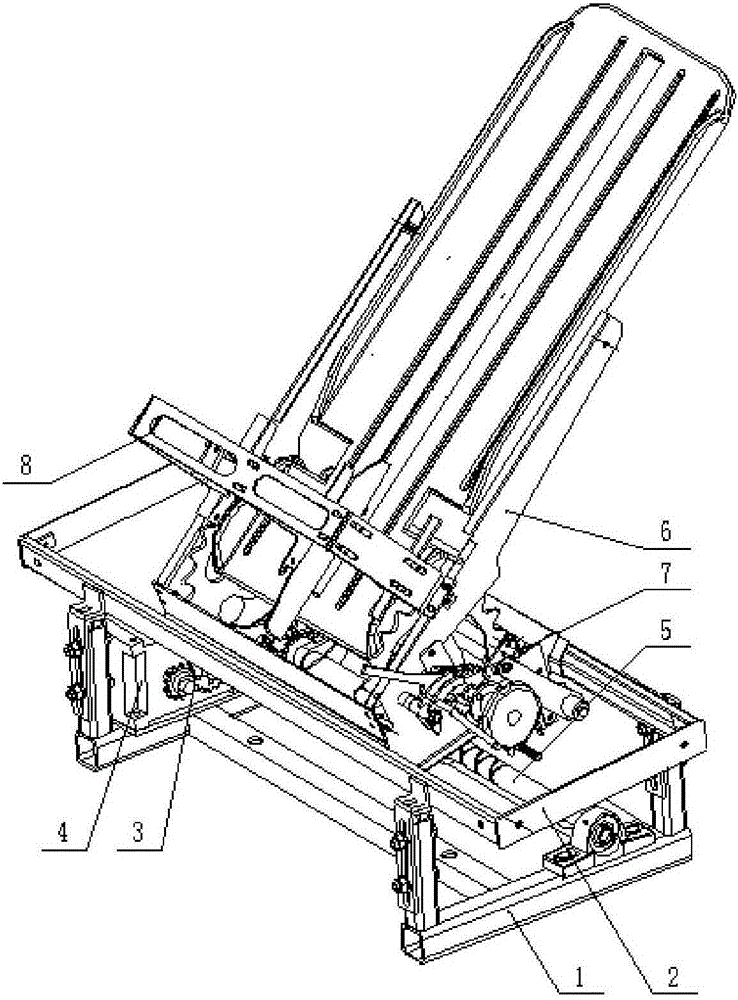

[0029] Such as figure 1 As shown, an automatic seedling feeding device for a pot seedling transplanter for dry land vegetables, including a frame assembly 1, a slide rail assembly 2, a chain transmission mechanism 3, a parallel indexing divider 4, a lateral moving box assembly 5, and a seedling box assembly 6. The vertical seedling delivery assembly 7 and the seedling pressing plate assembly 8.

[0030] Such as figure 1 and 2 As shown, the frame assembly 1 comprises a straight beam square tube 9, a cross beam square tube 10 and a column square tube 11; The column square tube 11 is welded; the two ends of the two beam square tubes 10 are welded with the inner surfaces of the two straight beam square tubes 9 respectively.

[0031] Slide rail assembly 2 comprises slide rail support plate 12, slide rail fixed piece 13, slide rail 14 and slide rail side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com