Jointing coal rock direct tensile test device and jointing coal rock direct tensile test method

A technology of tensile test and jointed coal rock, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of large deviation between test results and real values, and avoid bonding Difficult, avoid coal sample damage, avoid the effect of brittle coal cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

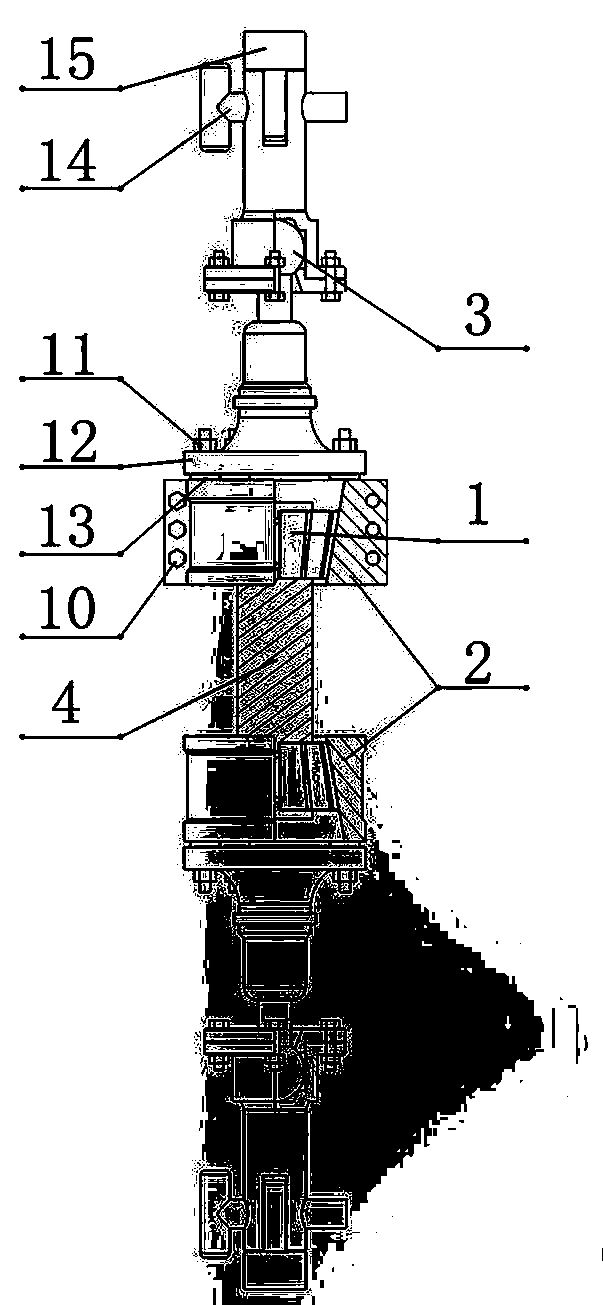

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

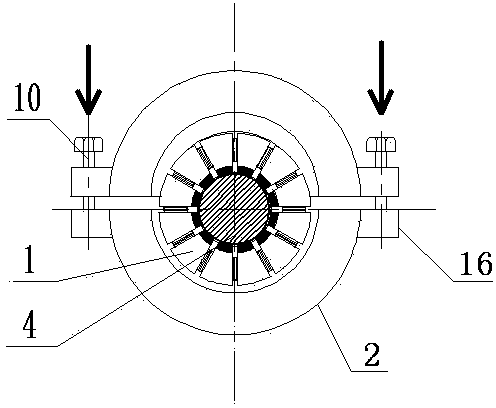

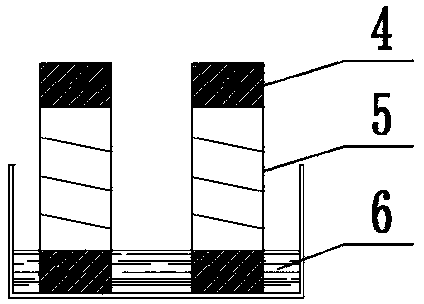

[0032] like figure 1 As shown in the figure, the jointed coal-rock direct tensile test device includes a taper sleeve of a card body, a spherical joint 3, and a tensile testing machine 15. The two ends of the coal sample 4 are respectively fastened by the taper sleeve of the card body, and each taper sleeve of the card body is connected. Corresponding ball joints 3 are connected to the tensile testing machine 15 . After the two ends of the coal sample 4 are respectively tightened by the taper sleeves of the card body, they are connected to the tensile testing machine 15 through the ball joint 3, and the tensile testing machine 15 conducts the tensile test on the coal sample 4. 1. Set it on the end of coal sample 4, and then install the cone sleeve 2. The outer surface of the card body 7 is completely fit with the inner wall of the cone sleeve 2. When stretching, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com