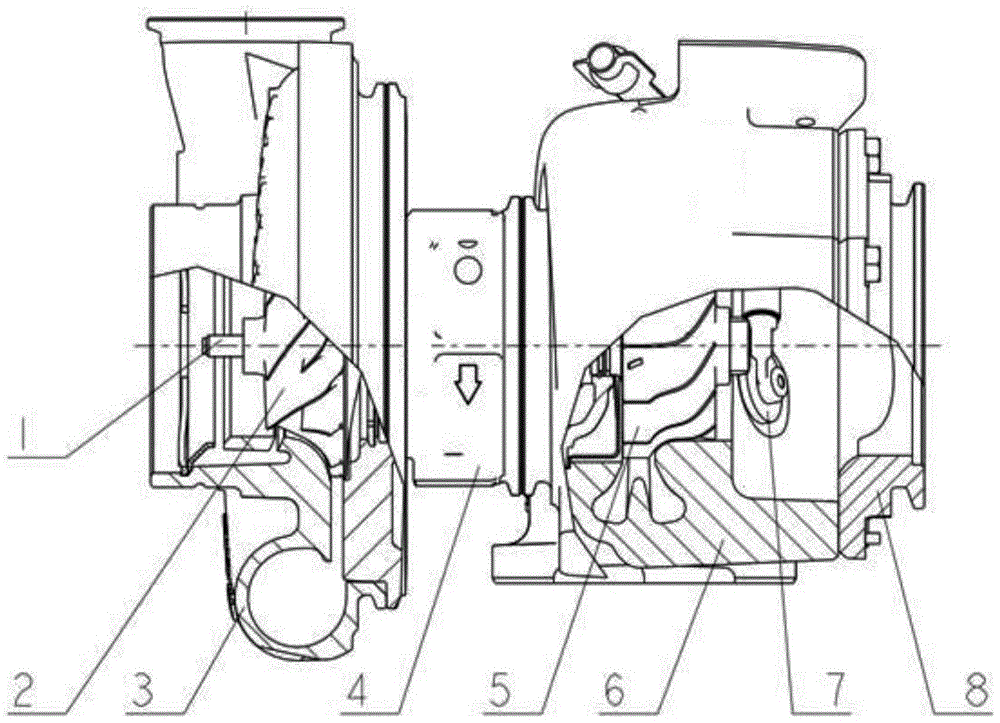

Turbocharger

A turbocharger, turbine technology, applied in machine/engine, engine components, internal combustion piston engine, etc., can solve problems such as not clarifying the best effect, achieve smooth flow, reduce entropy increase, and weaken turbulent flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

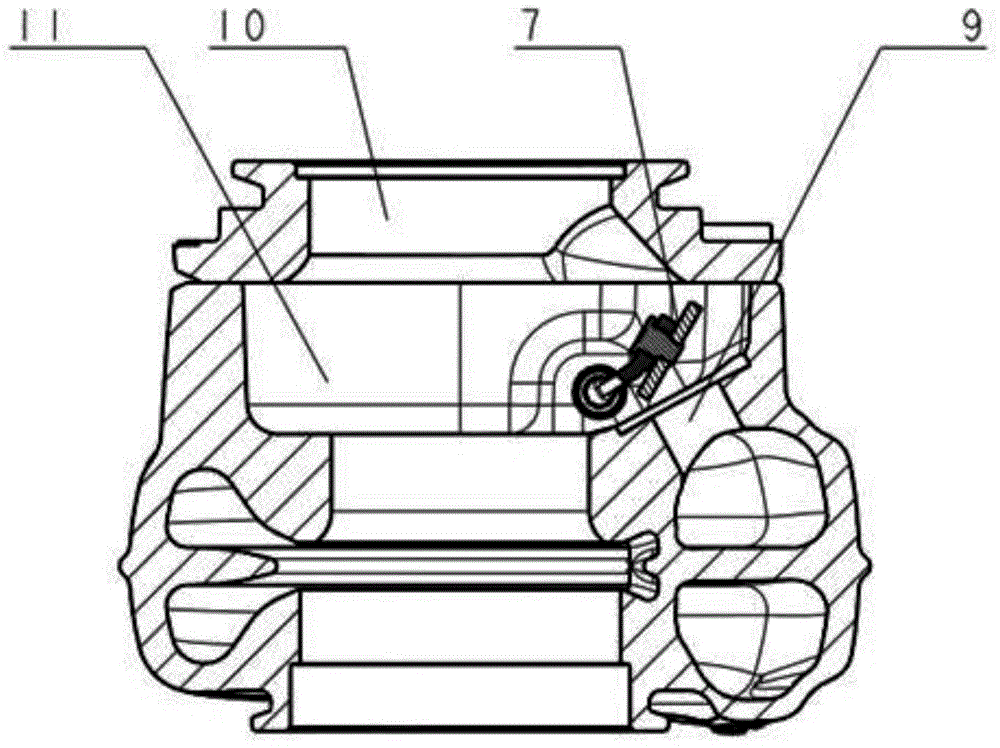

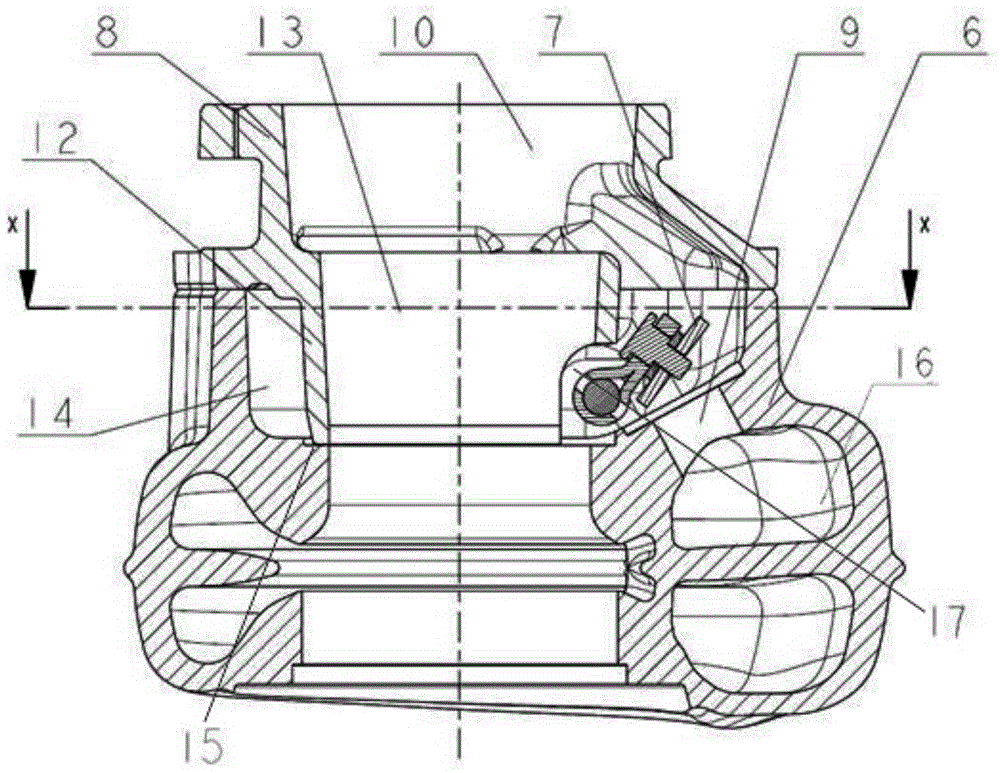

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0027] Such as image 3 , 4 As shown, a turbocharger of the present invention includes a turbine casing 6 with a flow passage 16, a bypass passage 9 communicating with the flow passage 16 is provided on the turbine casing 6, and the bypass passage 9 A bypass valve 7 is provided on the top, and a transition joint 8 is fixedly connected to the installation surface of the turbine casing 6. A partition wall 12 is provided on the side where the transition joint 8 is connected to the turbine casing 6, and the partition wall 12 extends into the turbine casing. In some special cases, due to space constraints, the positions of the partition wall 12 and the bypass valve 7 will partially overlap , at this time, an installation groove 17 can be provided on the partition wall 12 corresponding to the bypass valve 7; in other cases, there is no installation groove 17 here, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com