Steelmaking working procedure management system and method

A management system and process technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems that the production plan cannot fully consider the production conditions, the effectiveness of the production plan arrangement is not high, and the production situation analysis cannot be provided, etc., to achieve Solve the isolated island of information, produce accurate results, and record clearly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings, but the present invention will not be restricted in any way. Any changes or substitutions made based on the teachings of the present invention belong to the protection scope of the present invention.

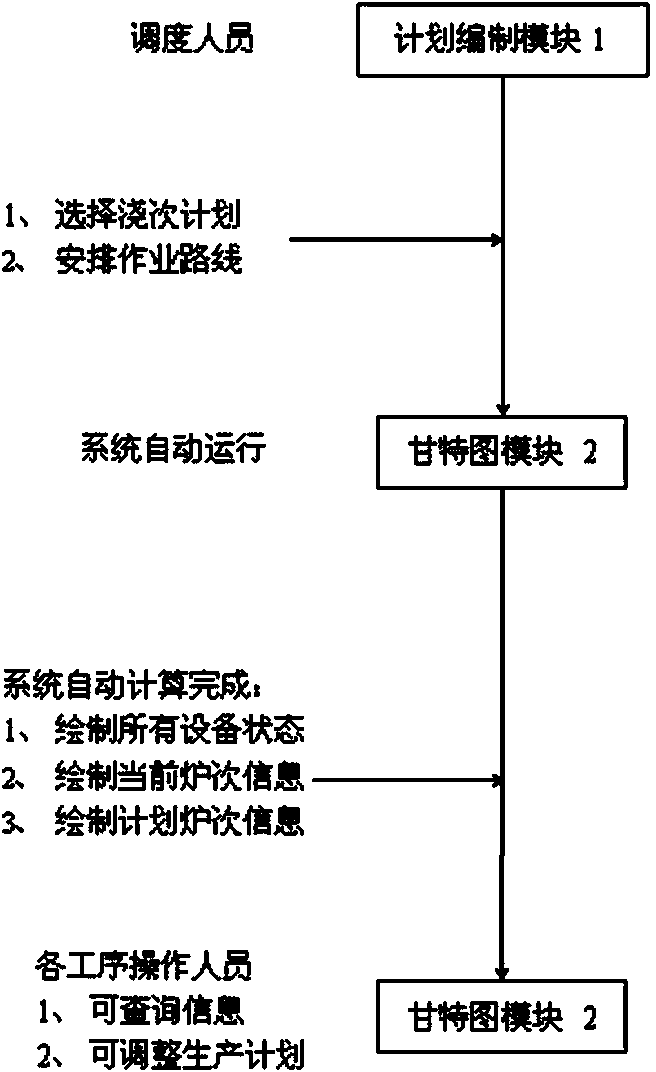

[0018] The steelmaking process management system of the present invention includes a terminal module, a planning module, a Gantt chart module, and a data storage module, wherein:

[0019] Terminal module: used for operators to operate the system;

[0020] Planning module: used to prepare production plans and store them in the data storage module;

[0021] Gantt chart module: used to call the equipment status of each process from the data storage module and draw the real-time situation of the production line, and draw the plan information according to the real-time situation of the production site;

[0022] Data storage module: used to store steelmaking process information.

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com