camera module

A camera module and lens assembly technology, which is applied to cameras, focusing devices of cameras, focusing devices of projectors, etc., can solve the problems of complex assembly process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The camera module will be described in detail below in conjunction with specific embodiments and drawings to make it more clear. However, the technical solutions of the camera module can be implemented in many different forms, and are not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the camera module more thorough and comprehensive.

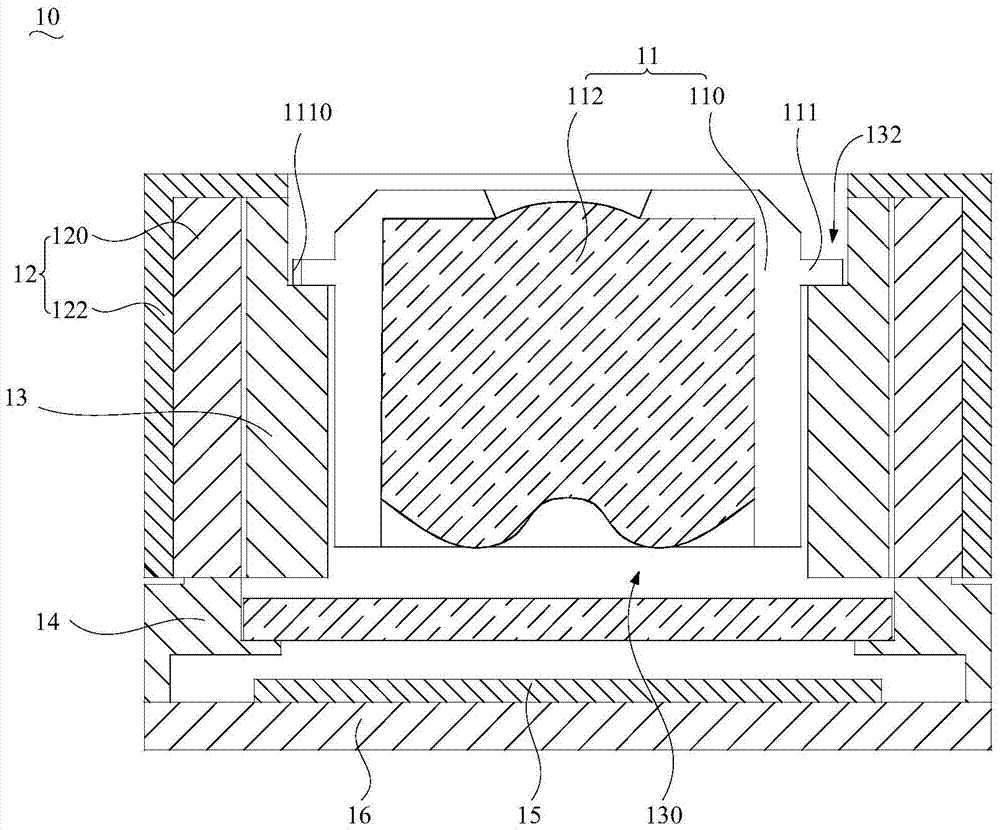

[0027] see Figure 1 to Figure 3 , in the first embodiment, the camera module 10 includes a lens assembly 11 , a driving mechanism 12 , a connector 13 and a bracket 14 .

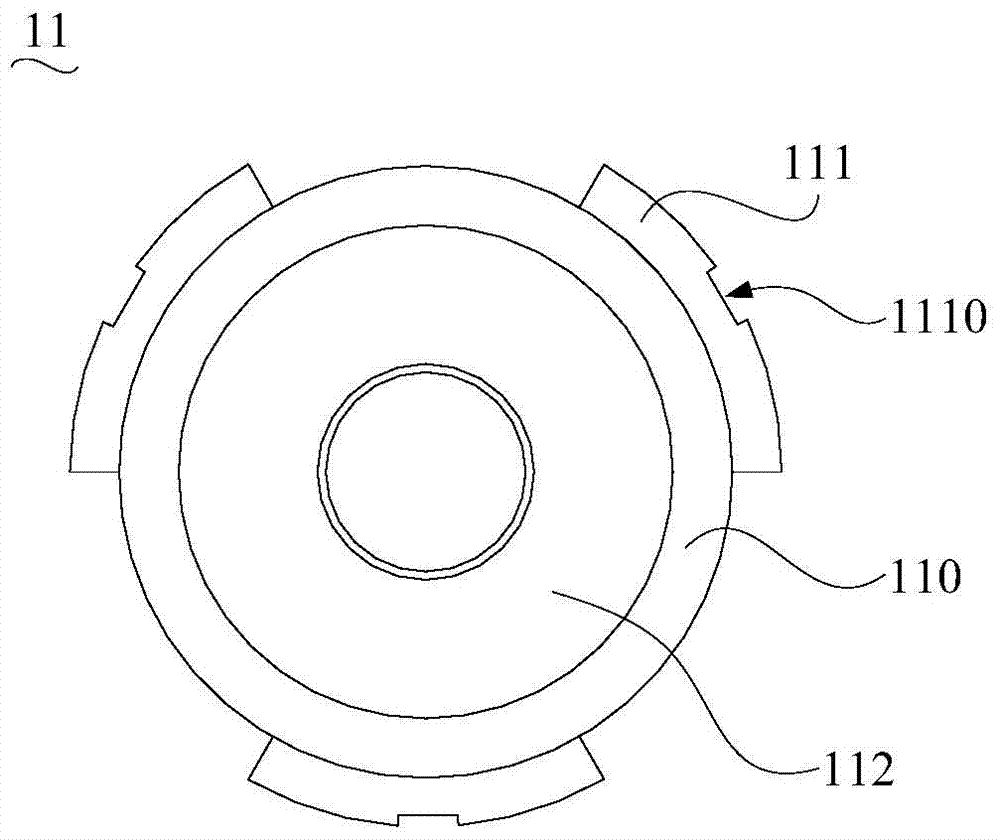

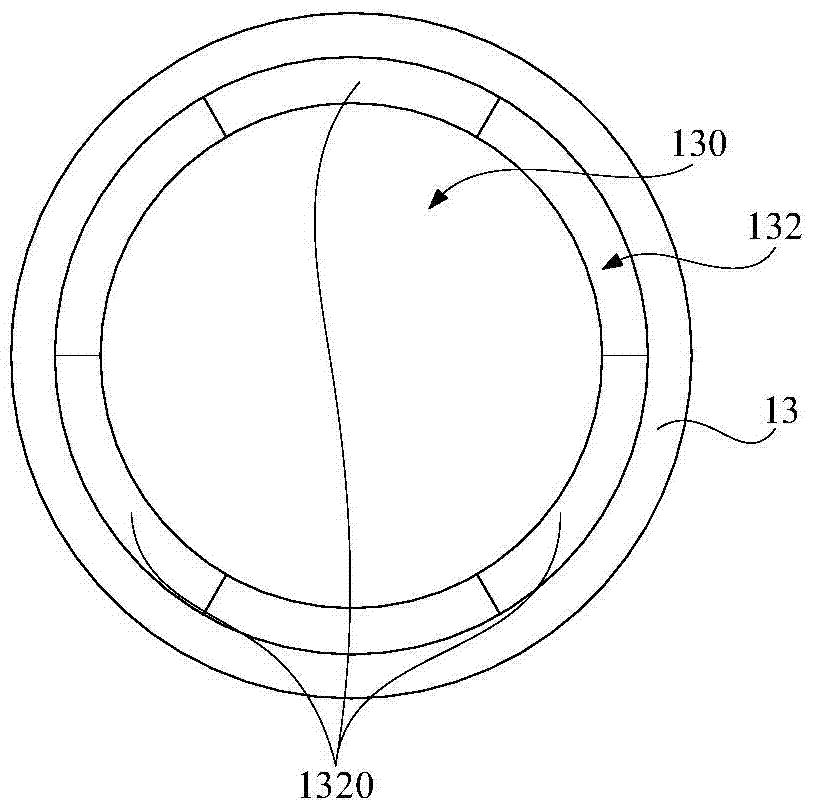

[0028] The lens assembly 11 includes a lens barrel 110 and an optical element 112 built in the lens barrel 110 . The driving mechanism 12 is mounted on the bracket 14 , and the connecting piece 13 is movably accommodated in the driving mechanism 12 . The connecting piece 13 defines a through hole 130 , and the lens assembly 11 is embedded in the through hole 130 . In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com