A method and device for evaluating the emulsification effect of an emulsifier for emulsion explosives

A technology of emulsified explosives and extrusion devices, which is applied in the field of evaluation of the emulsification effect of emulsifiers, to achieve the effect of small dose, high reliability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

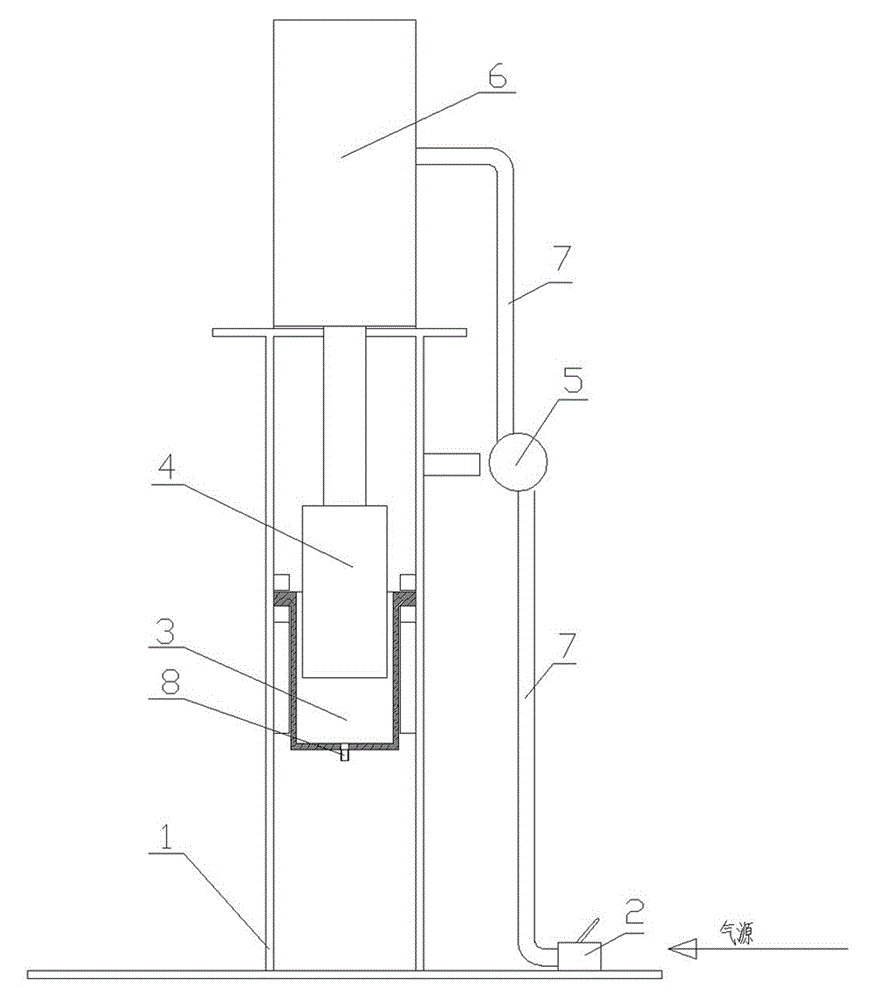

[0022] The structure of the emulsification effect evaluation device is as follows: figure 1 As shown, it consists of three parts: bracket, extrusion device and pneumatic mechanism. The pneumatic mechanism includes an air source, an air pump 6 fixed above the bracket 1 and an air pipe 7 for connecting the air source and the air pump, and an air pump starting and running direction adjustment switch 2 and a pressure gauge 5 are arranged on the air pipe 7 . The extruding device is composed of extruding tank 3 and extruding rod 4. There is a small hole in the middle of the bottom of the extruding tank 3, which is detachably installed on the bracket 1. The connector 8 of the hole, one end of the extruding rod 4 is fixed on the air pump 6, and the other end is located above the extruding tank 3, driven by the air pump 6, and moves up and down in the extruding tank.

Embodiment 2

[0024] Using the emulsification effect evaluation device of Example 1, the emulsification effects of three commercially available emulsifiers were evaluated by the emulsification effect evaluation method of the present invention. Wherein, emulsifier A is T152 emulsifier produced by Changzhou Cambridge Chemical Plant, emulsifier B is 2727B emulsifier produced by Lubrizol, and emulsifier C is T152 emulsifier produced by Shanxi Yongji Hongyuan Chemical Plant.

[0025] According to the following ratio, use each emulsifier to prepare 300g emulsification base for evaluation test: 73.5wt% ammonium nitrate, 20wt% water, 1.5wt% emulsifier, 5wt% 32# machine oil.

[0026] Mix ammonium nitrate and water under heating conditions to form a water phase, and control the temperature of the water phase to 80°C.

[0027] Mix the emulsifier with 32# mechanical oil, heat and melt to form an oil phase, control the temperature of the oil phase to 50°C, and keep it warm in a water bath.

[0028] Add...

Embodiment 3

[0041] Using the emulsification matrix formula and emulsification conditions in Example 2, 0# diesel oil was used instead of 32# mechanical oil, and the obtained emulsification matrix was repeatedly squeezed 15 times, and the hole diameter of the squeeze tank connector was 1 mm. The test conditions are shown in Table 4.

[0042]

[0043] The obtained results show that the emulsifying effect of the emulsifier is B>C>A, which is consistent with the result of Example 2.

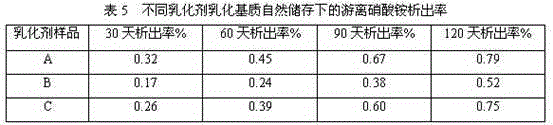

[0044] Its natural storage conditions are shown in Table 5.

[0045]

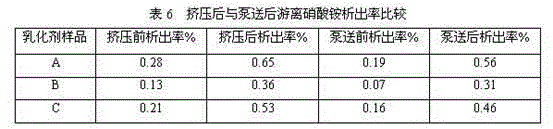

[0046] According to this emulsification formula, the experiment was carried out on the emulsified explosive production line, and then the emulsified matrix was repeatedly pumped 15 times with a screw pump, and the pumping pressure was 0.15MPa. This result was compared with the situation after extrusion using the emulsification effect evaluation device, and the results are shown in Table 6.

[0047]

[0048] The comparison results s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com