A self-balancing two-way flapper valve for shock absorbers

A self-balancing, baffle valve technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., to achieve the effect of light weight, simple structure and friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

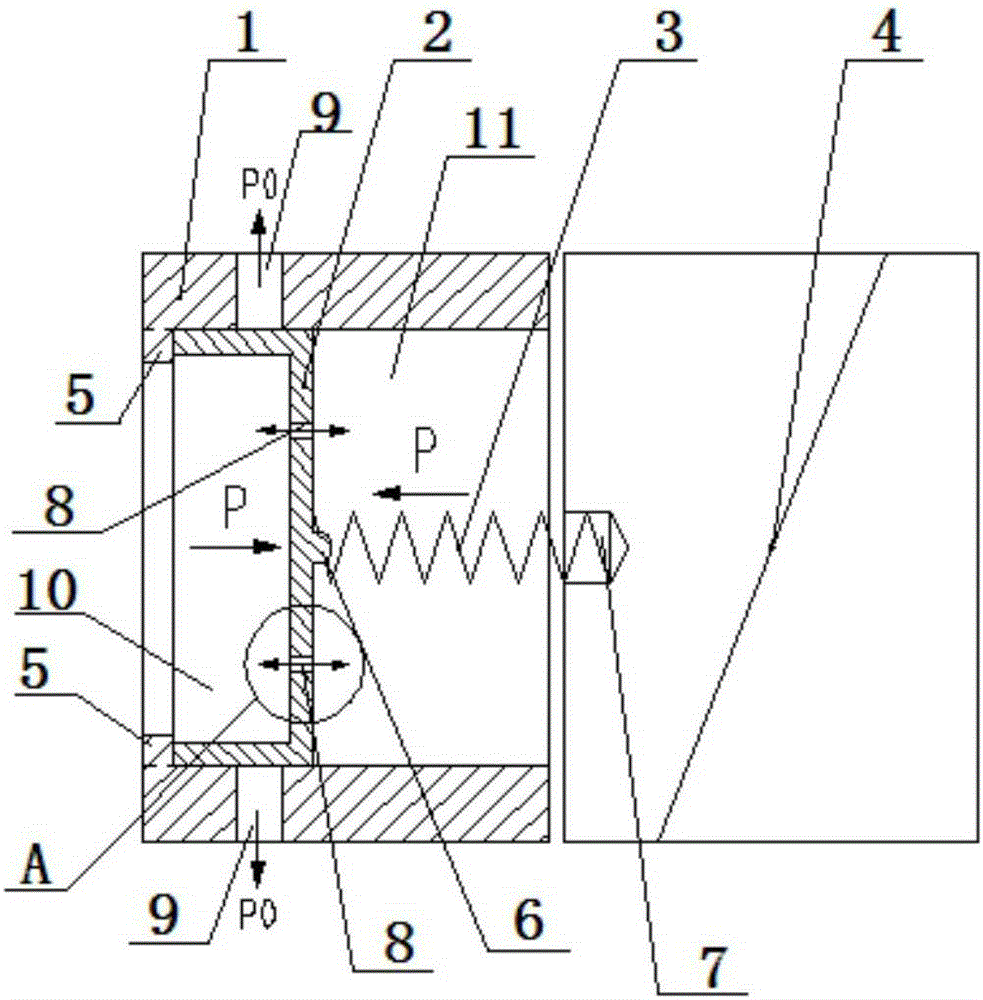

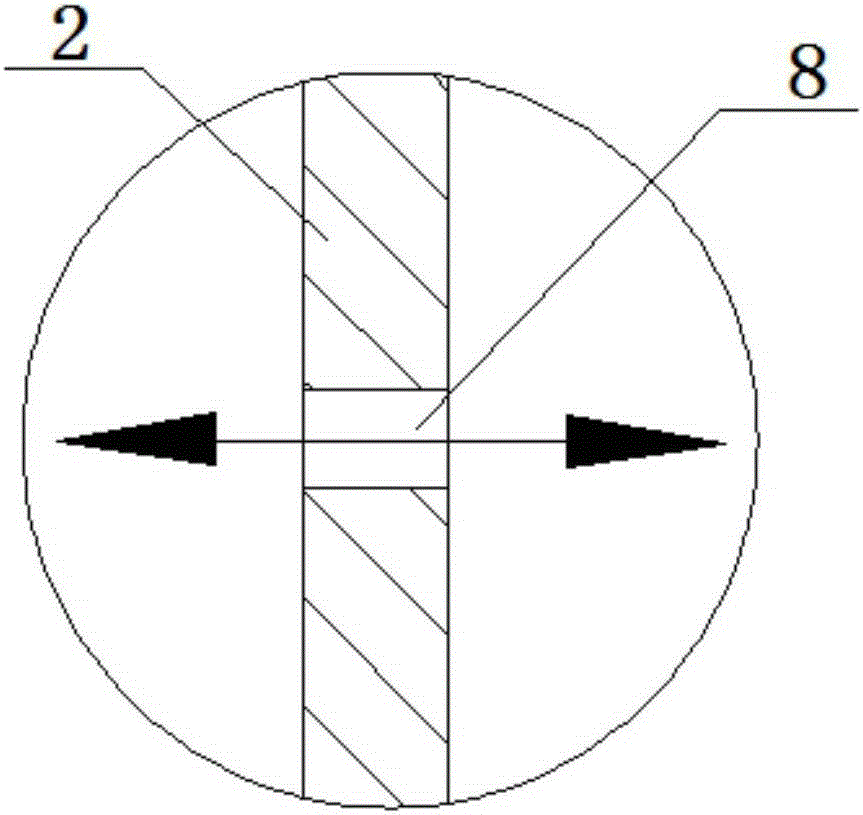

[0028] This embodiment provides a self-balancing two-way baffle valve for shock absorbers, the structure of which is as follows: figure 1 and 2 As shown, it includes a baffle valve body 1 with an inner cavity, a baffle valve core 2 arranged in a gap between the inner cavity of the baffle valve body 1 and the baffle valve body, and a driving device arranged on one side of the baffle valve body 1 4 and the return spring 3 connecting the baffle spool 2 with the driving device 4, wherein the gap between the baffle spool and the baffle valve body is 0.5-1 mm, and the driving device adopts an electromagnet, and the circulating The oil is hydraulic oil:

[0029] The section of the baffle valve core 2 is a U-shaped structure and divides the baffle valve body 1 into a left chamber 10 and a right chamber 11. The baffle valve body 1 is evenly distributed along the circumferential direction with at least four oil holes 9 for hydraulic oil circulation. , the baffle valve body 1 is far aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com