One-time injection moulding septic tank

An injection molding and septic tank technology, applied in the field of one-shot injection molding septic tanks and septic tanks, can solve the problems of high cost, easy leakage of feces to pollute the environment, long construction period, etc., and achieves good results and is conducive to disease prevention. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

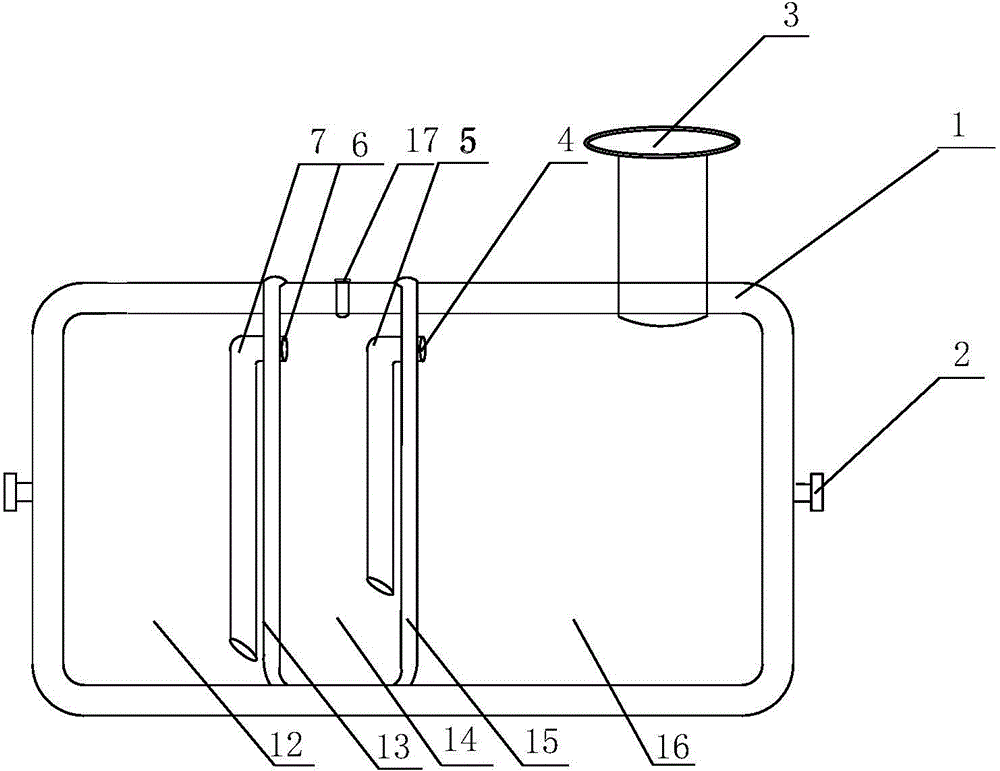

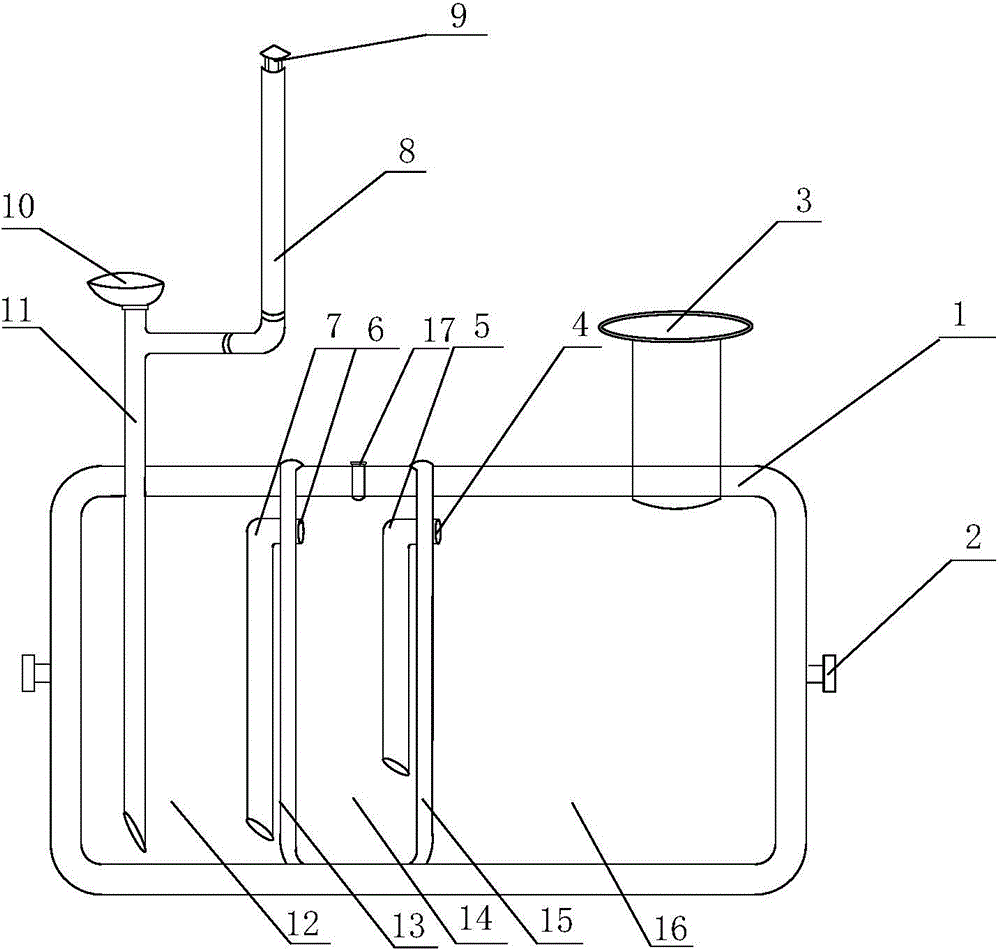

[0018] refer to figure 2 The one-time injection molding septic tank is used in a harmless toilet, including a toilet 10, a septic tank main body 1, and the septic tank main body 1 is fastened into a whole by two half boxes through fastening bolts 2. The above-mentioned septic tank body 1 is provided with a septic tank partition 13 and a septic tank partition 15 with two compartments. Two grid septic tanks 14 are formed between the first lattice septic tank partition 13 and the second grid septic tank partition 15, and the second grid septic tank 14 is provided with a slag removal port 17; the first grid septic tank partition 13 and the One septic tank main body constitutes a septic tank 12; two septic tank partitions 15 and one septic tank main body constitute a three-compartment septic tank 16. The above-mentioned one-grid septic tank partition 13 and the two-compartment septic tank partition 15 are respectively shaped with feces guide holes, and the primary fecal passage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com