Feed tension stabilizing device for central line of zipper

A constant tension, center line technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of inconsistent tension, low adjustment work efficiency, insufficient tension adjustment function, etc., to reduce the difference, The effect of simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

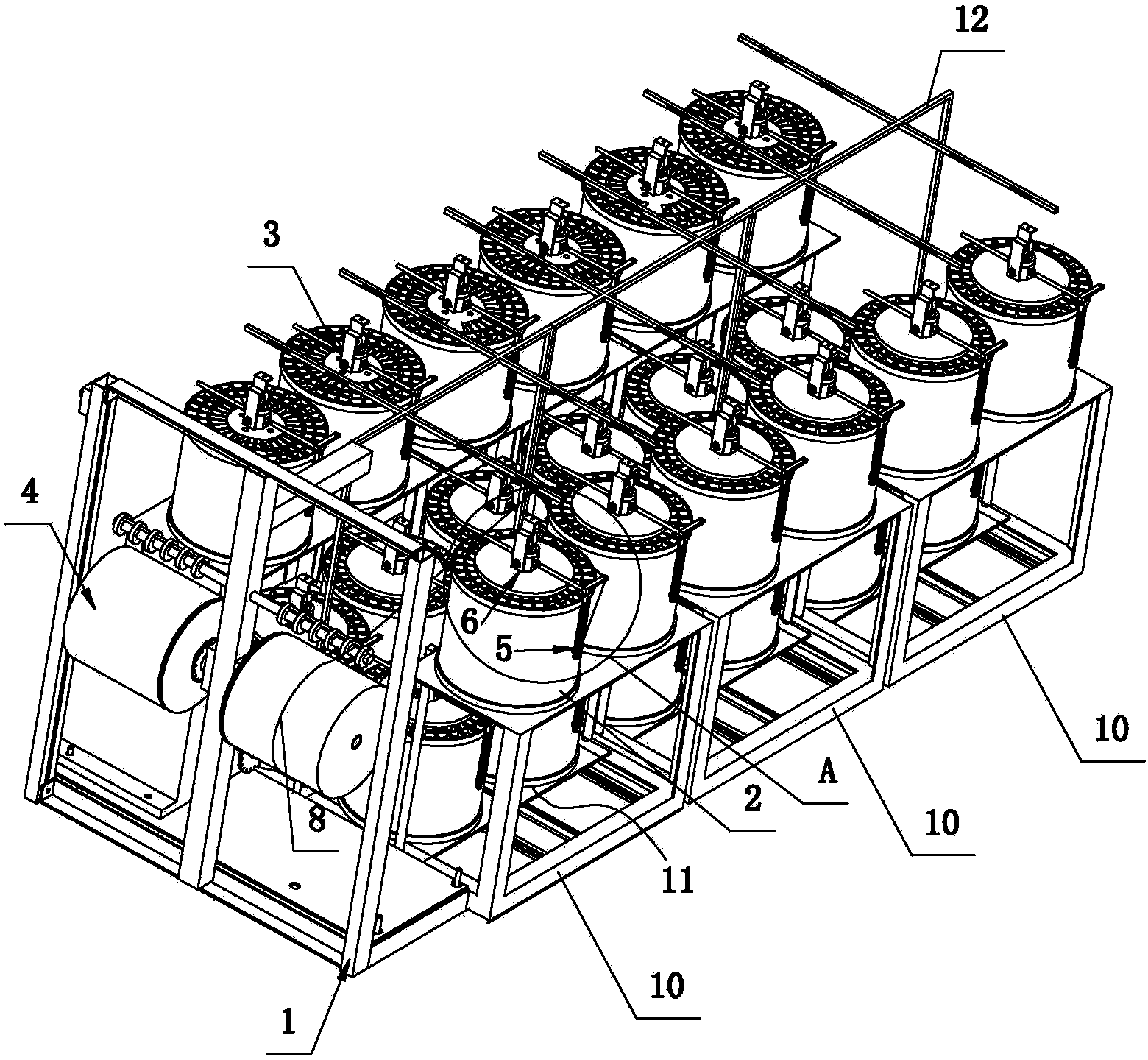

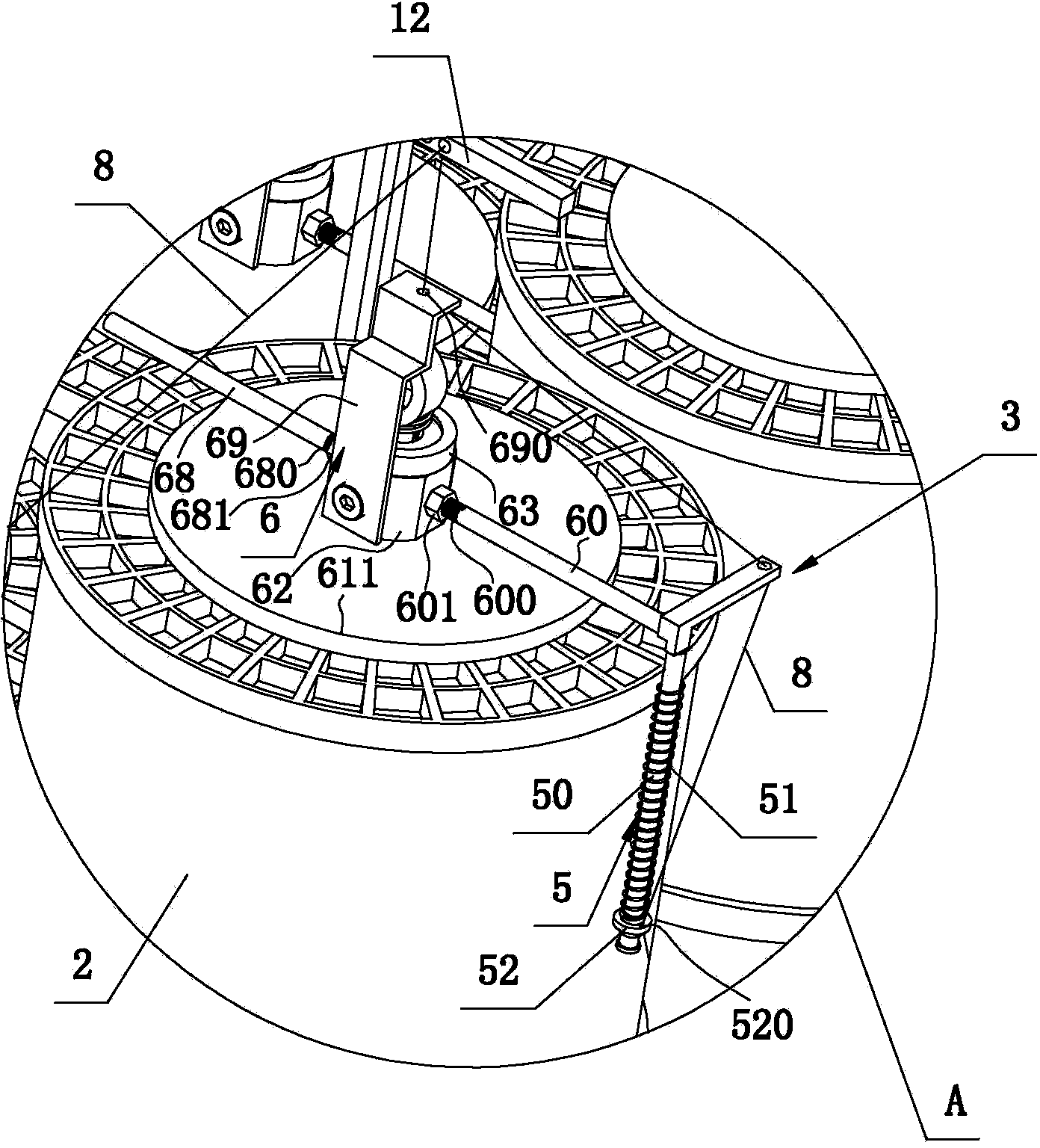

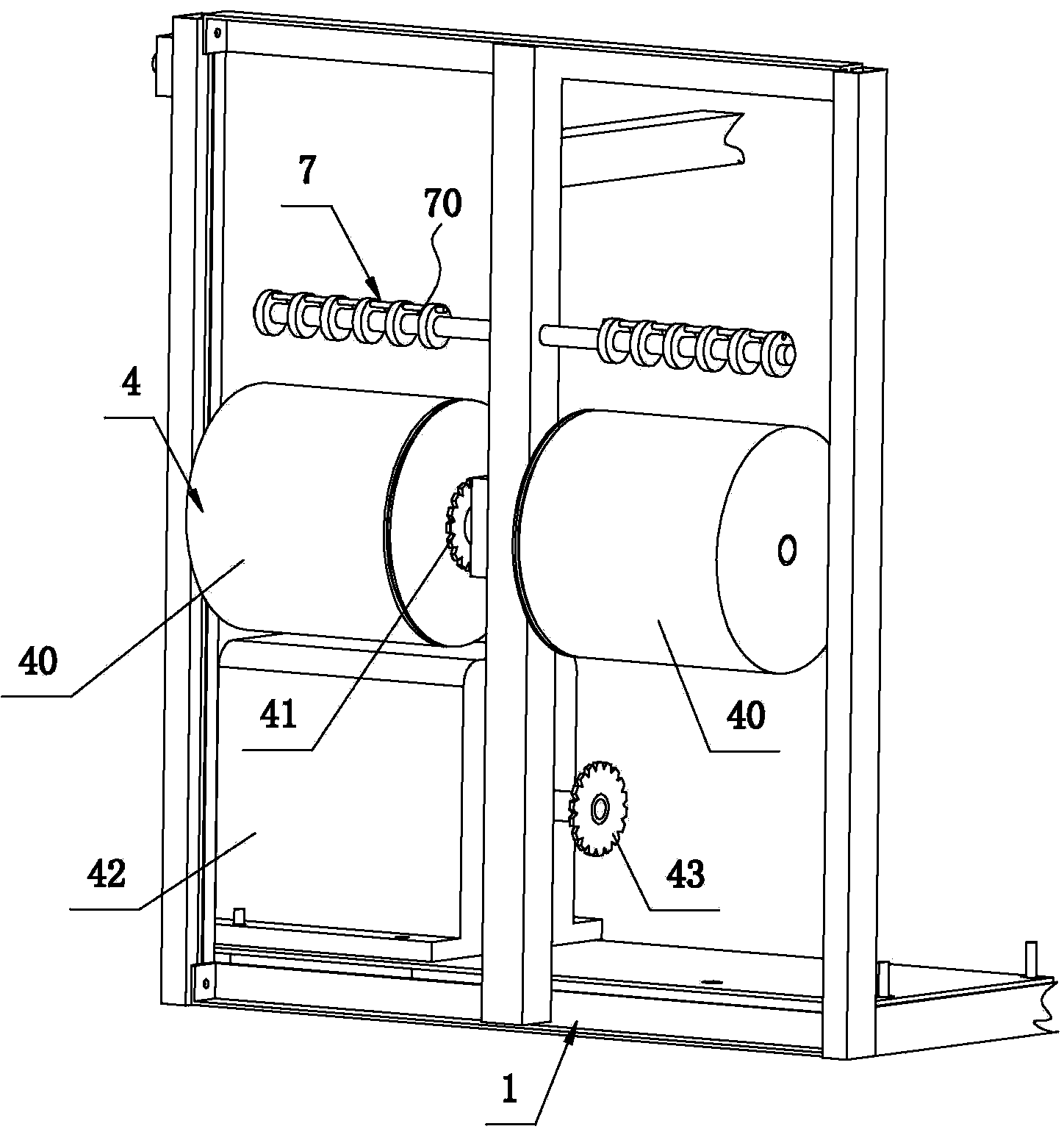

[0032] refer to figure 1 , figure 2 , image 3 with Figure 4. A device for feeding constant tension on the centerline of a zipper, comprising a bracket 1, at least one I-shaped cylinder 2 fixedly installed on the bracket 1, a wire arrangement mechanism 3 above the I-shaped cylinder 2, and a centerline 8 for pulling the centerline 8 from the row The driving mechanism 4 dragged away from the wire mechanism 3, the wire arranging mechanism 3 is rotatably installed above it relative to the I-shaped cylinder 2, and is correspondingly arranged on one side of the winding position of each I-shaped cylinder 2 There is a tension adjustment mechanism 5, which includes a longitudinally arranged guide rod 50, a compression spring 51 set on the guide rod 50, and a sleeve set on the guide rod 50 and abutting on the compression spring 51. The adjustment slider 52 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com