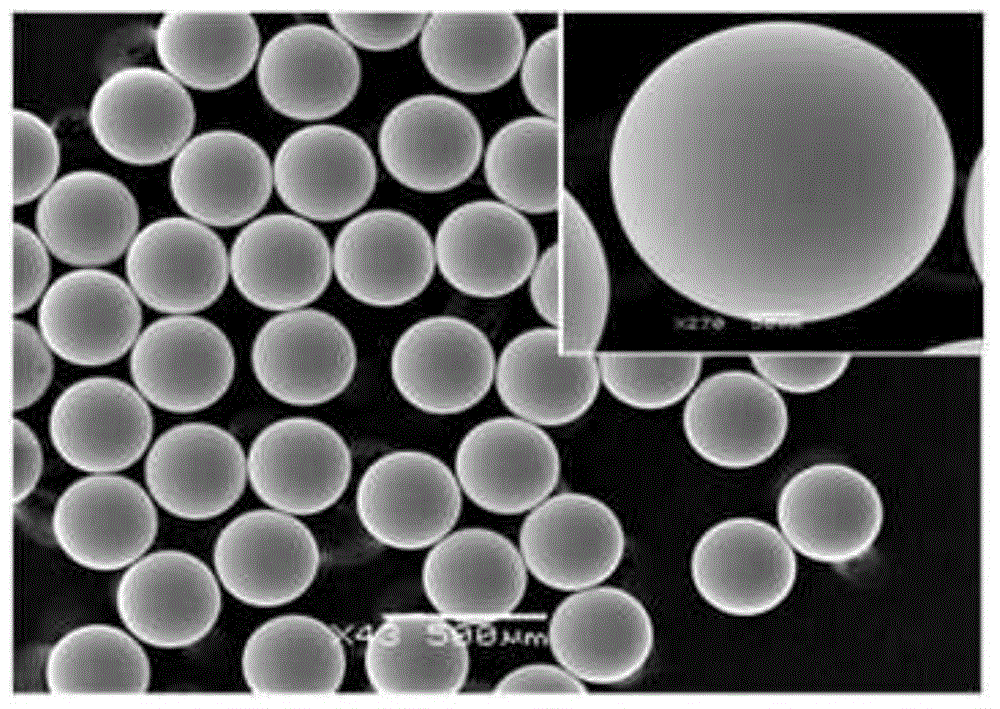

Method and device for manufacturing metallic glass particles

A metallic glass and particle technology, which is applied in the field of metallic glass preparation, can solve the problems of uneven distribution of particle size, inconsistent thermal history, and low cooling rate, and achieve consistent thermal history, easy realization, and increased range of differential pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as figure 1 and 2A device used in a method for preparing metallic glass particles is shown, the device includes a vacuum system, a droplet ejection system, an image acquisition system and a particle collection device, the vacuum system includes a vacuum chamber 7, and the particle collection device is installed on The bottom of the vacuum chamber, the droplet injection system is installed on the top of the vacuum chamber, and is located directly above the particle collection device, the image acquisition system is connected to the vacuum chamber of the vacuum system, and the baffle 11 is movably installed on the droplet through the bracket 12 Between the injection system and the particle collection device, the purpose of setting the baffle plate is to remove particles that do not conform to the size at the beginning or form an oxide layer on the surface, so as to improve the yield of the product. Particles of different sizes are not mixed together.

[0036] The v...

Embodiment 2

[0051] Embodiment 2 is the same as the device and the preparation method of metallic glass particles in embodiment 1, and the different relevant parameters of the device and method of this embodiment are as follows:

[0052] (1) The small holes of the device are two holes distributed on a circular arc with the center of the ceramic sheet as the center, and the angle between the two holes is 180°, the aperture range of the small holes is 0.020mm, and the speed of preparing particles is 0.020 mm. 2 times that of Example 1.

[0053] (2) The vibration frequency of piezoelectric ceramics is 600Hz; the crucible and ceramic sheet are made of Al 2 o 3 ; The transmission rod is made of Al 2 o 3 .

[0054] (3) Step (1) charging: adding the metal to be prepared is Cu-Hf alloy.

[0055] (4) Step (2) evacuating: using a mechanical pump and a diffusion pump to evacuate the crucible and the vacuum chamber to 0.0009Pa.

[0056] (5) Step (3) molten metal: after the Cu-Hf alloy is complet...

Embodiment 3

[0059] Embodiment 3 is the same as the device and the preparation method of metallic glass particles in embodiment 1, and the different relevant parameters of the device and method of this embodiment are as follows:

[0060] (1) The small holes of the device are 4 holes distributed on a circular arc centered on the center of the ceramic sheet, and the angle between each hole is 90°, the small hole aperture range is 0.600mm, and the speed of preparing particles is 4 times that of Example 1.

[0061] (2) The vibration frequency of piezoelectric ceramics is 1200Hz; the making material of crucible 3 and ceramic sheet 9 is ZrO 2 , the transmission rod 2 is made of ZrO 2 .

[0062] (3) Step (1) charging: the metal to be prepared is Zr-Cu-Al alloy.

[0063] (4) Step (2) evacuating: using a mechanical pump and a diffusion pump to evacuate the crucible and the vacuum chamber to 0.0008Pa.

[0064] (5) Step (3) molten metal: the Zr-Cu-Al alloy is completely melted and then kept for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com