Corn thresher

A threshing machine and corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of unclean threshing and easy interruption, and achieve the effects of large processing capacity, prevention of breakage, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

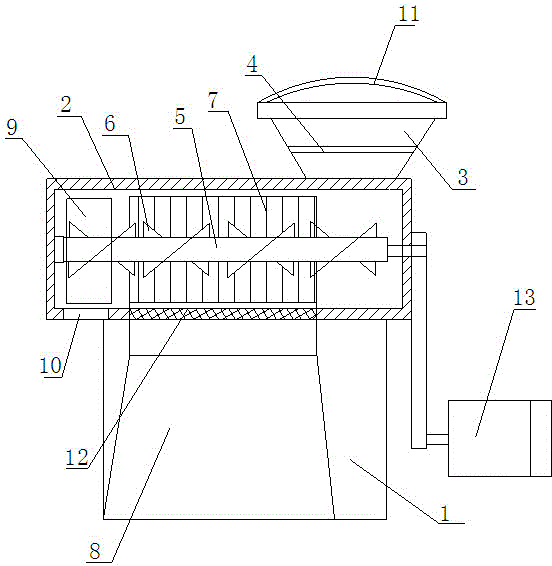

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] like figure 1 As shown, the corn thresher of the present invention comprises a cabinet 1, the top of the cabinet 1 is connected to the threshing box 2, and one end of the threshing box 2 is connected to the feed box 3, and the inner wall of the feed box 3 is provided with a heating wire 4, in order to dry the corn cobs quickly , is conducive to threshing, and prevents corn cobs from breaking during the threshing process. A rotary blade assembly is provided in the threshing box 2. The rotary blade assembly includes a rotating shaft 5 and a helical blade 6 arranged on the rotating shaft 5. The rotating shaft 5 is driven by a motor 13. The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com