Wire winding method and device for wire winding type strainmeter

A strain gauge and wire-wound technology, which is applied in the field of manufacturing resistance strain gauges, can solve problems such as low pass rate, low material utilization rate, and no wire-wound strain gauges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

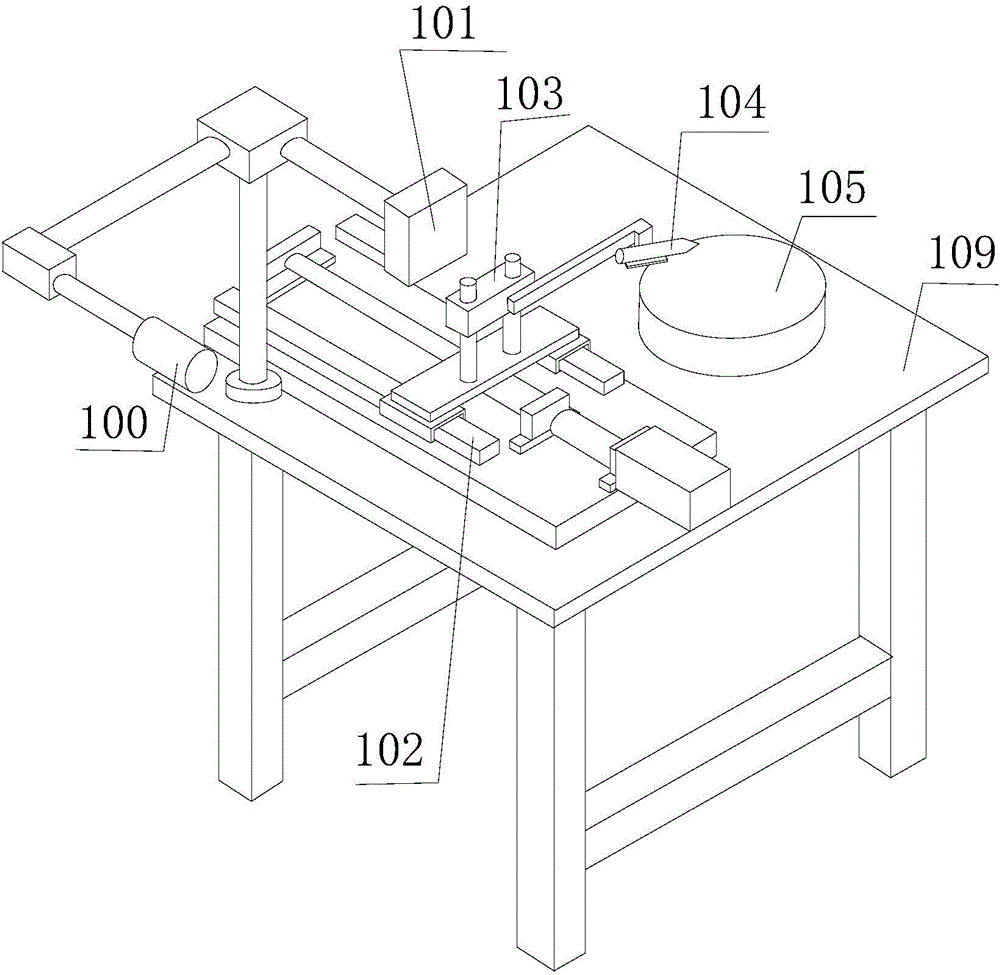

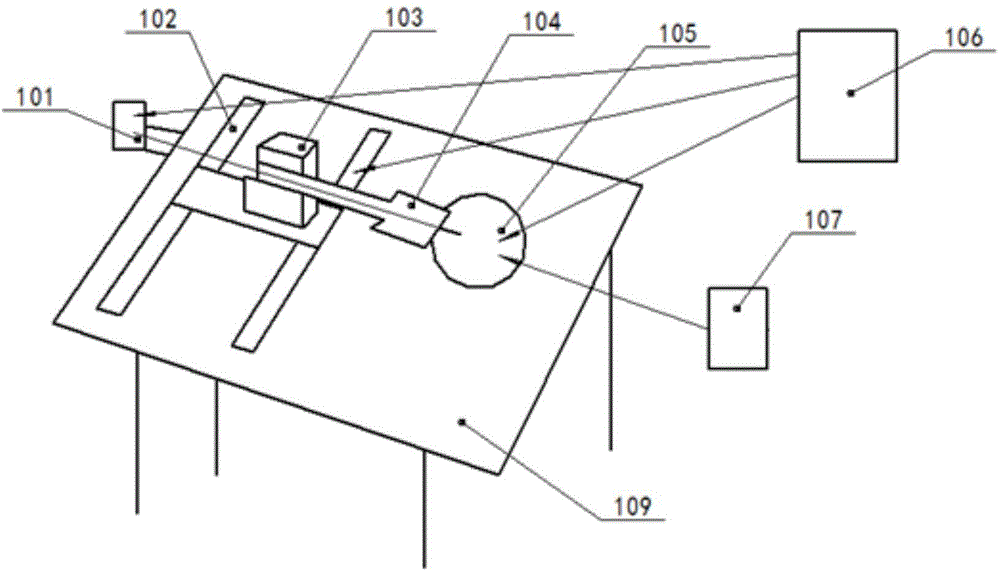

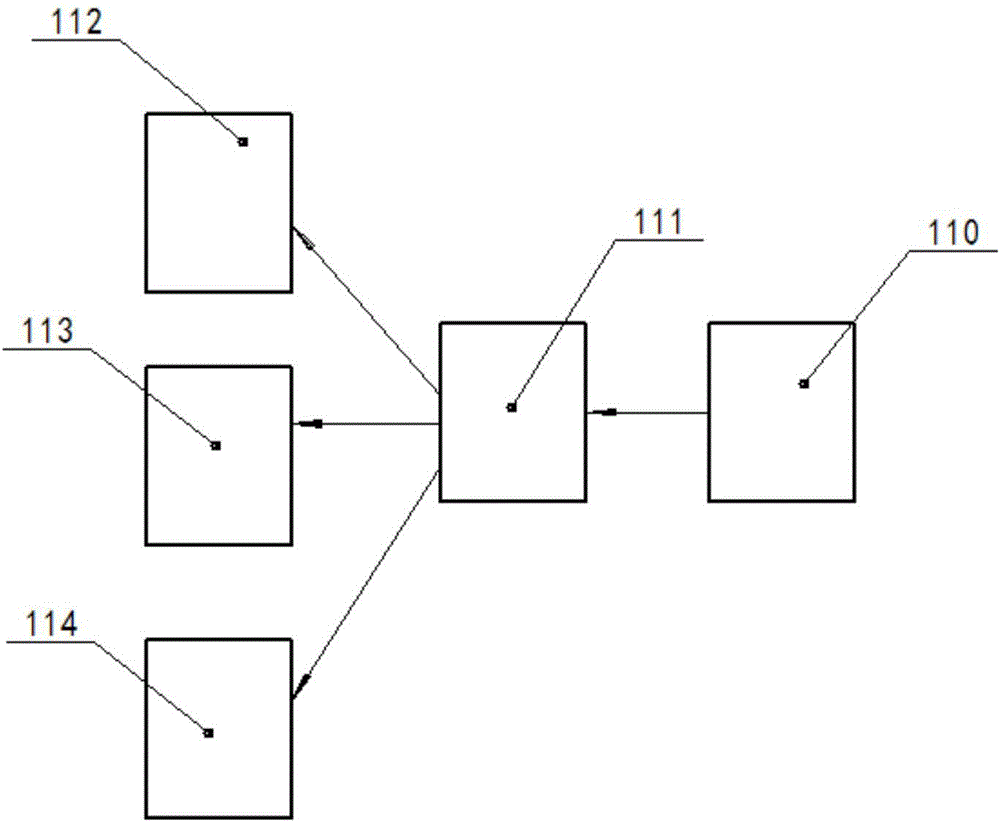

[0022] The present invention provides a wire-wound strain gauge wire winding device and method. The strain gauge base film is adsorbed on the strain gauge base adsorption device 105, and the wire to be wound is controlled by the industrial computer 106 to send the wire into the wire feeding mechanism 101 Put the glue in the glue-filling silk outlet device 104, stick it on the base film of the strain gauge after stretching out, use the industrial computer 106 to control the linear motion system 102 to drive the mechanical arm 103 and the glue-filling silk outlet device 104 to do linear motion, At the same time, the strain gauge base adsorption device 105 is controlled to rotate, so that the motion tracks of the wire and the base film are synthesized into a helical line, and finally the required wire-wound strain gauge is formed.

[0023] The suction device for the strain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com