An annealing process of an aluminum alloy coil

An annealing process, an aluminum alloy technology, applied in the annealing process field of aluminum alloy coils, can solve the problems of shortening the annealing time, the difference in the microstructure and properties of the coil head and tail of the finished material, etc., so as to shorten the annealing time, monitor the annealing temperature, and achieve a remarkable production effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put 6 volumes of 1 series 1060, 0.25×1020×C aluminum alloy coils produced by casting and cold rolling according to the normal process into a 50-ton electric heating annealing furnace, and insert thermocouples on the outside and inside of the first coil near the furnace door;

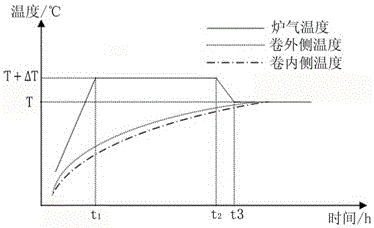

[0017] The annealing process is set as follows: the annealing target temperature T of the aluminum alloy coil is 330°C, the ΔT is set to 90°C, and the Δt is set to 30°C. The alloy coil is heated up rapidly, and the temperature rise rate is controlled at 2.4°C / min. At the same time, the temperature of the outer high temperature point of the aluminum alloy coil is monitored. When the monitored outer high point temperature of the coil reaches 330°C-30°C, the annealing furnace The air temperature drops to 330°C, and the cooling time is 90 minutes. When the monitored inner low point temperature of the aluminum alloy coil reaches (330°C-10°C), keep warm for 60 minutes and air cool.

[0018] After anneal...

Embodiment 2

[0020] Put 4 rolls of 1 series 1060, 0.15×1000×C aluminum alloy coils produced by casting and cold rolling according to the normal process into a 25-ton electric heating annealing furnace, and insert thermocouples on the outside and inside of the first roll near the furnace door;

[0021] The annealing process is set as follows: the annealing target temperature T of the aluminum alloy coil is 390°C, the ΔT is set to 20°C, and the Δt is set to 15°C. The alloy coil is heated up rapidly, and the heating rate is controlled at 2.4°C / min. At the same time, the temperature of the externally measured high temperature point of the aluminum alloy coil is monitored. When the monitored high temperature on the outside of the coil reaches 390°C-15°C, the furnace The air temperature drops to 390°C, and the cooling time is 70 minutes. When the monitored low temperature of the inner side of the aluminum alloy coil reaches (390°C-25°C), heat preservation for 80 minutes and air cooling.

[0022]...

Embodiment 3

[0024] According to the above raw material ratio, 4 volumes of 3003, 0.25×1020×C aluminum-magnesium coils produced by casting and cold rolling according to the normal process are put into a 25-ton electric heating annealing furnace, and inserted on the outside and inside of the first volume near the furnace door. upper thermocouple;

[0025] The annealing process is set as follows: the annealing target temperature T of the aluminum alloy coil is 360°C, the ΔT is set to 110°C, and the Δt is set to 40°C. The aluminum alloy coil is heated up rapidly, and the temperature rise rate is controlled at 3 / min. At the same time, the temperature of the external high temperature point of the aluminum alloy coil is monitored. The air temperature drops to 360°C, and the cooling time is 75 minutes. When the monitored inner low point temperature of the aluminum alloy coil reaches (360°C-20°C), keep warm for 120 minutes and air cool.

[0026] After annealing, the finished state of aluminum an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com