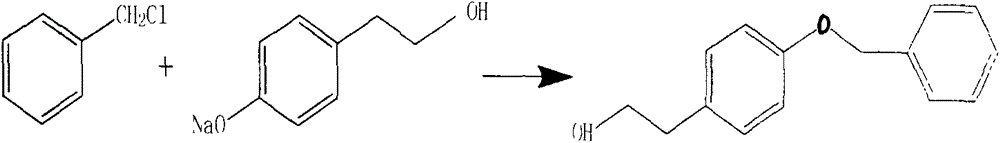

Preparation method of 2-(4-benzyloxyphenyl) ethanol

A technology of benzyloxyphenyl and hydroxyphenylethanol, which is applied in the field of preparation of 2-ethanol, can solve the problems of low product yield, long reaction route, poor production efficiency, etc., and achieve high product yield and low product by-products Less, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Add 200ml of water and 50g of p-hydroxyphenylethyl alcohol into a 1000ml three-necked bottle, stir and mix evenly, and add the pre-configured sodium hydroxide solution (16.5g of sodium hydroxide + 50ml of water) dropwise at room temperature for 2 hours; , under reduced pressure distillation at 0.085MPa vacuum, about 200ml of water is evaporated, stop steaming; add 250ml of toluene to reflux with water, heat up to reflux state, reflux with water until there is no water, keep reflux for 1.5h after bringing water; cool down, temperature When the temperature is lower than 30°C, start to add 50g of benzyl chloride dropwise, and the dropping time is controlled within 1h; after the dropwise addition, raise the temperature to reflux 100°C, and keep the temperature for 25h; Stir at ℃ for 0.5h, then stand still for 0.5h to separate layers, extract the organic layer and cool it down to below 20℃, stir slowly to crystallize for 8h to crystallize, filter to obtain a wet product, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com