A self-heating tank with a double-layer lid

A double-layered, self-heating technology, applied in food heating containers, rigid containers, packaged foods, etc., can solve problems such as mis-pulling products and failures, and achieve the effects of balancing pressure difference, low cost, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

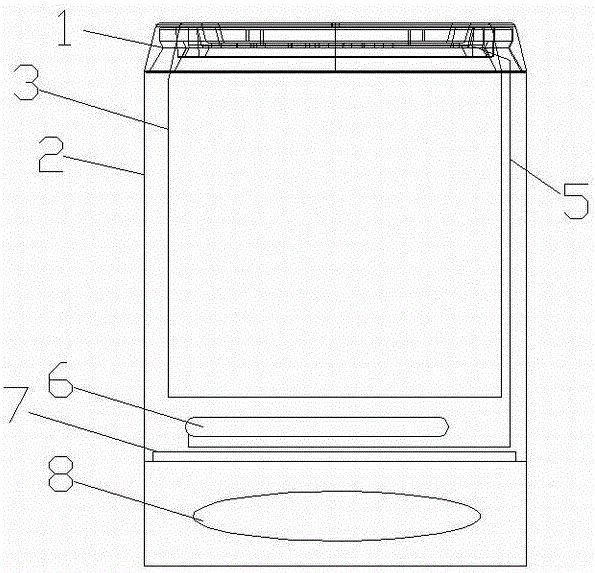

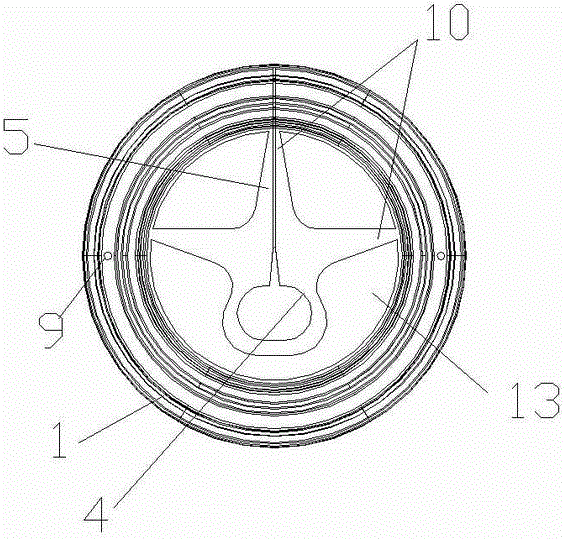

[0018] Attached below figure 1 , 2 , 3, 4 describe the present invention in detail:

[0019] A self-heating tank with a double-layer cover, which includes a double-layer cover 1, the double-layer cover 1 has an outer layer card slot 11 and an inner layer card slot 12; the outer layer card slot 11 and the outer layer The layer tank 2 is snap-connected, and the inner layer card slot 12 is snap-connected with the tank 3 to be heated;

[0020] The middle part of the double-layer cover 1 is an easy-pull loop structure 4, and a drawstring 5 is fixed on the back of the easy-pull loop structure 4, and the other end of the drawstring 5 is connected to the water bag 6 in the outer tank 2 For fixing, the water bag 6 is fixedly connected to the fixing plate 7; the self-heating bag 8 is placed on the bottom of the outer tank 2.

[0021] A plurality of vent holes 9 are opened on the double-layer cover body 1.

[0022] The outer edge of the easy-pull ring structure 4 is connected to the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com