Polyvinyl alcohol film and preparation method thereof

A polyvinyl alcohol film, polyvinyl alcohol technology, applied in the field of optical materials, can solve problems such as poor tensile properties, affecting the imaging quality of liquid crystal displays, and polarizer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

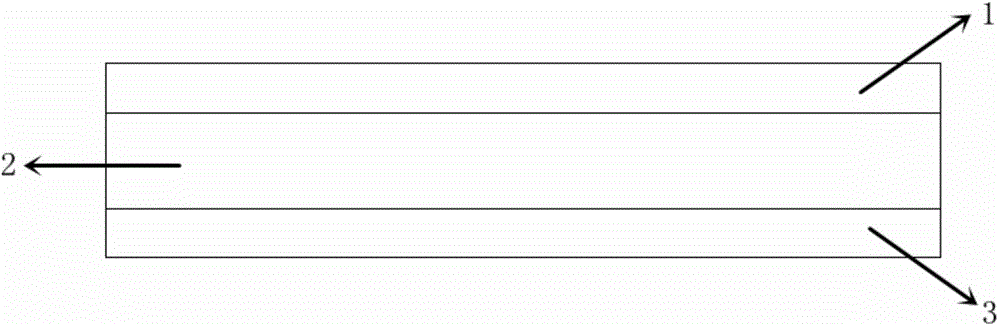

Image

Examples

preparation example Construction

[0060] The present invention also provides a kind of preparation method of polyvinyl alcohol film, comprises the following steps:

[0061] melting and co-extruding the first component, the second component and the third component to obtain a polyvinyl alcohol film;

[0062] The first component includes first polyvinyl alcohol, and the degree of polymerization of the first polyvinyl alcohol is 3000-4000;

[0063] The second component includes a second polyvinyl alcohol, and the degree of polymerization of the second polyvinyl alcohol is 1000-3000;

[0064] The third component includes third polyvinyl alcohol, and the degree of polymerization of the third polyvinyl alcohol is 3000-4000.

[0065] In the present invention, the first component is consistent with the first component in the above technical solution, and will not be repeated here. In the present invention, the components included in the first component are preferably mixed to obtain the first component;

[0066] In...

Embodiment 1

[0076] Mix 100 parts by mass of polyvinyl alcohol with a degree of polymerization of 3500 and a degree of alcoholysis of 99.5%, 13 parts by mass of glycerol, 0.1 part by mass of lauric acid diethanolamide and 220 parts by mass of water to obtain the first component;

[0077] Mix 150 parts by mass of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99.5%, 19.5 parts by mass of glycerol, and 329 parts by mass of water to obtain the second component;

[0078] Mix 100 parts by mass of polyvinyl alcohol with a degree of polymerization of 3500 and a degree of alcoholysis of 99.5%, 13 parts by mass of glycerol, 0.1 part by mass of lauric acid diethanolamide and 220 parts by mass of water to obtain a third component;

[0079] Using a three-layer dissolving co-extrusion equipment, the obtained first component, second component and third component were simultaneously extruded and cast on a steel belt at 90°C, and after drying for 5 minutes, polyvin...

Embodiment 2

[0089] Mix 100 parts by mass of polyvinyl alcohol with a degree of polymerization of 3200 and a degree of alcoholysis of 99.7%, 10 parts by mass of glycerol, 0.3 parts by mass of lauric acid diethanolamide and 300 parts by mass of water to obtain the first component;

[0090] Mix 150 parts by mass of polyvinyl alcohol with a degree of polymerization of 2000 and a degree of alcoholysis of 99.2%, 15 parts by mass of glycerol, and 450 parts by mass of water to obtain the second component;

[0091] Mix 100 parts by mass of polyvinyl alcohol with a degree of polymerization of 3200 and a degree of alcoholysis of 99.7%, 10 parts by mass of glycerol, 0.3 parts by mass of lauric acid diethanolamide and 300 parts by mass of water to obtain a third component;

[0092] Using a three-layer dissolving co-extrusion equipment, the obtained first component, second component and third component were simultaneously extruded and cast on a steel belt at 90°C, and after drying for 5 minutes, polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com