Dust collector with motor suspension fixing structure

A fixed structure, vacuum cleaner technology, applied in the installation of suction hoses, motor fan components, etc., can solve the problems of no innovation in reducing vibration, increased vibration of the dust box, and no great improvement in the effect, so as to avoid destructive Deformation, improve the comfort of use, eliminate the effect of working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

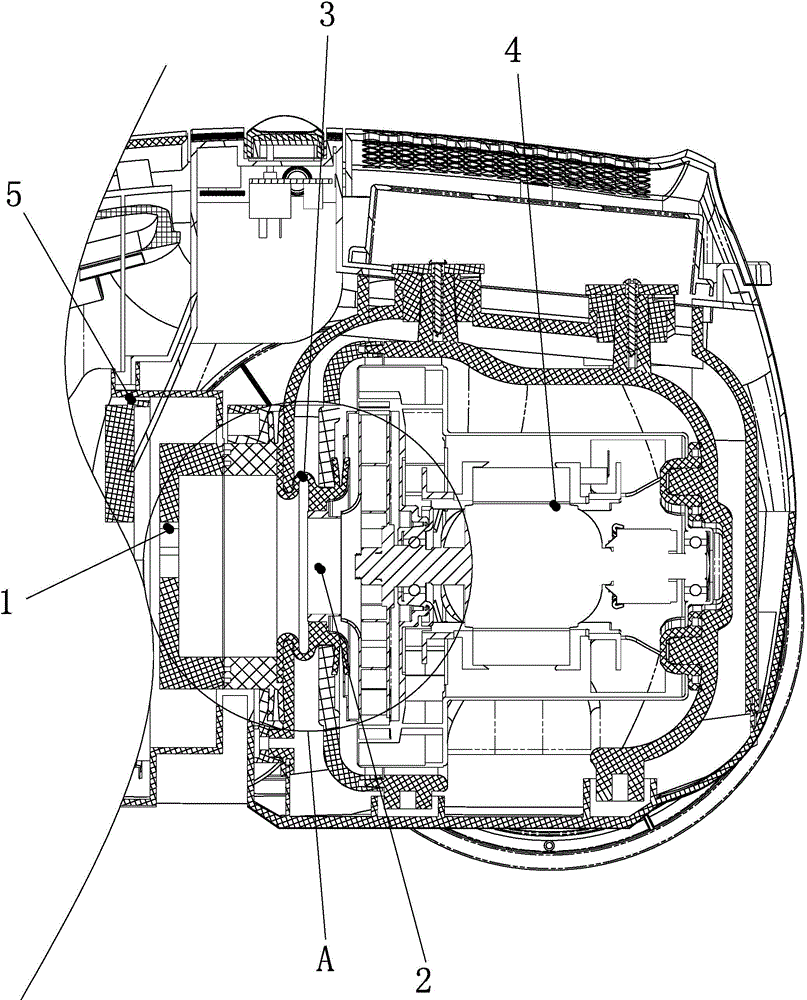

[0022] Figure 1 to Figure 4 A specific embodiment of the vacuum cleaner with the motor suspension fixing structure of the present invention is shown. The vacuum cleaner includes a motor 4 and a dust box 5, wherein the dust box 5 is provided with a dust box air outlet 1, and the motor 4 is provided with a motor suction. The air outlet 2 and the motor air inlet 2 are made of plastic parts. The motor 4 is composed of a motor body and a motor casing that accommodates the motor body. The motor air suction port 2 is provided on the motor casing.

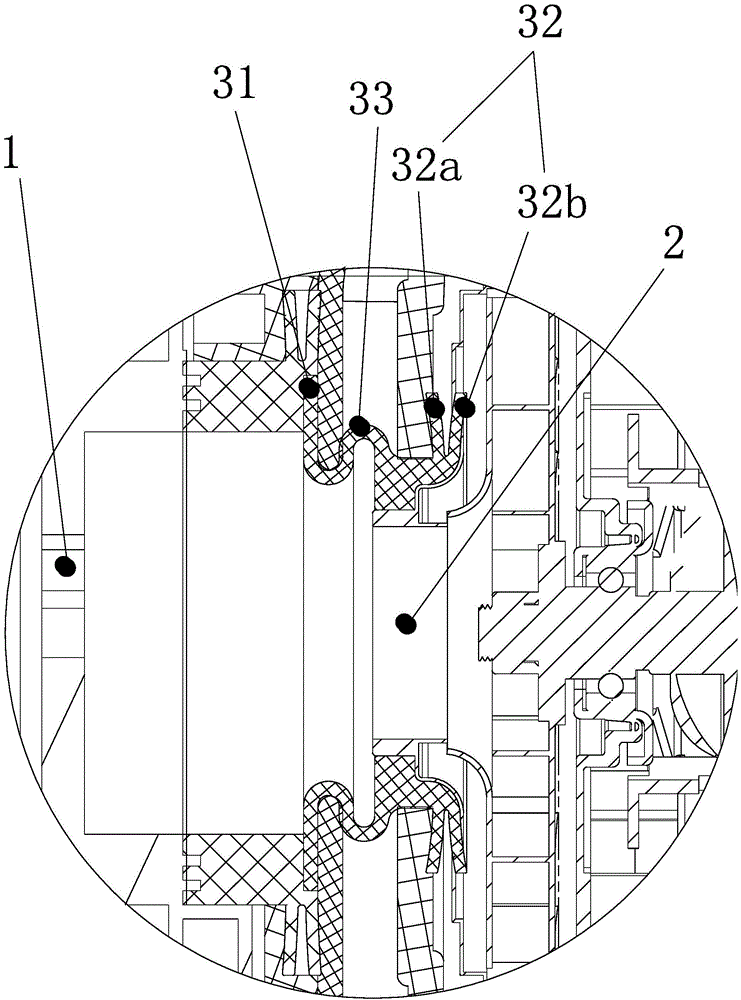

[0023] The key improvement of this embodiment is that a retractable and flexible air duct 3 is sealed and connected between the dust box air outlet 1 and the motor air suction port 2 . The air outlet 1 of the dust box and the air inlet 2 of the motor are in sealed communication through the flexible air duct 3, which can produce both axial expansion and contraction deformation and circumferential torsional deformation.

[0024] The flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com