Colored photosensitive composition, black photo spacer, and color filter

A photosensitive composition and photopolymerization technology, applied in optical filters, photosensitive materials for optomechanical equipment, optics, etc., can solve problems such as damage characteristics, curability of spacer layers, etc., to ensure light Effects of absorbing and maintaining voltage retention and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0387] [Manufacturing method of colored photosensitive composition]

[0388] The colored photosensitive composition of the present invention is prepared according to a conventional method. Hereinafter, although an example is given and it demonstrates concretely, the manufacturing method of the coloring photosensitive composition in this invention is not limited to this method.

[0389] From the viewpoint of ensuring the dispersion stability of the pigment, the coloring photosensitive composition of the present invention is preferably prepared in the following manner to prepare a pigment dispersion liquid in advance and to mix other components therein.

[0390] [1] Manufacturing method of pigment dispersion liquid

[0391] Predetermined amounts of the pigment, solvent, and dispersant, and, if necessary, a dispersion aid are weighed, and in the dispersion treatment step, the pigment is dispersed to obtain a liquid pigment dispersion. In this dispersion treatment step, a paint ...

Embodiment

[0432] Hereinafter, although an Example and a comparative example are given and this embodiment is demonstrated more concretely, this embodiment is not limited to the following example unless the summary is exceeded. In addition, below, "part" means a "weight part."

[0433] The constituent components of the colored photosensitive composition used in the following examples and comparative examples are as follows.

[0434]

[0435]"ZCR-1569H" manufactured by Nippon Kayaku Co., Ltd. (MW = 3000 to 4000, acid value = about 100 mg-KOH / g)

[0436] In addition, this binder resin-1 corresponds to "alkali-soluble resin (A)" in this invention.

[0437]

[0438] "ZCR-1642H" manufactured by Nippon Kayaku Co., Ltd. (MW = 5000 to 6500, acid value = about 100 mg-KOH / g)

[0439] In addition, this binder resin-2 corresponds to "alkali-soluble resin (A)" in this invention.

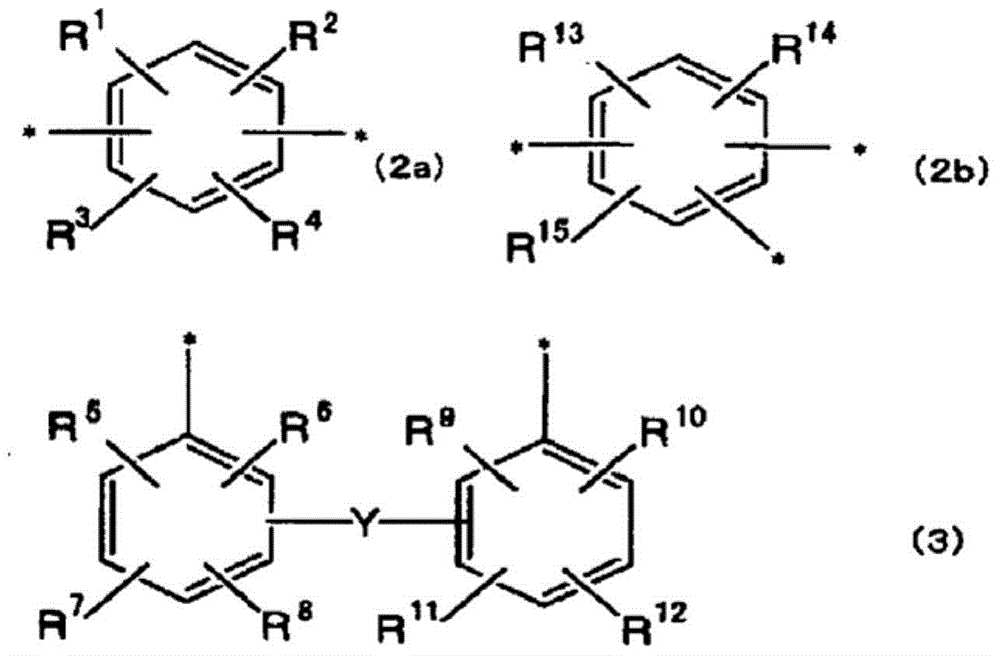

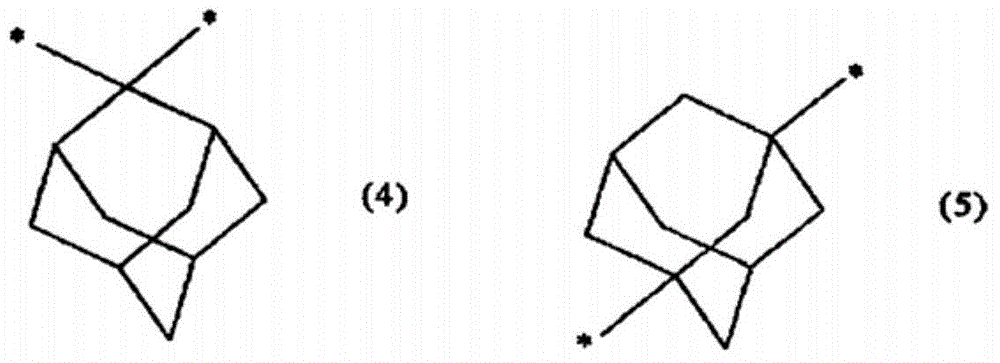

[0440]

[0441] Resin (MW=3500-4500, acid value = about 110 mg-KOH / g)

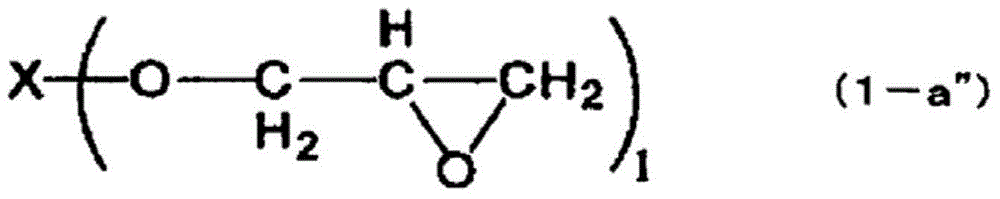

[0442] [chemical formula 21]

[0443]...

Synthetic example 1

[0445]

[0446] Add 50g of epoxy compound (epoxy equivalent 264) of above structure (11), 13.65g of acrylic acid, 60.5g of methoxybutyl acetate, 0.936g of triphenylphosphine and 0.032g of p-methoxyphenol into a thermometer equipped with , a stirrer, and a flask with a cooling tube, the reaction was carried out at 90° C. while stirring until the acid value became 5 mgKOH / g or less. The reaction required 12 hours, and an epoxy acrylate solution was obtained.

[0447] 25 parts by weight of the above-mentioned epoxy acrylate solution and 0.74 parts by weight of trimethylolpropane (TMP), 3.95 parts by weight of biphenyltetracarboxylic dianhydride (BPDA), 2.7 parts by weight of tetrahydrophthalic anhydride (THPA) It was added to the flask equipped with the thermometer, the stirrer, and the cooling tube, and it heated up slowly to 105 degreeC, stirring, and it was made to react.

[0448] When the resin solution became transparent, it was diluted with methoxybutyl acetate, and it p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com