Wiper for vehicle

一种刮水器、车辆的技术,应用在车辆保养、车辆的清洗、运输和包装等方向,能够解决刮水片小型化困难等问题,达到抑制张开的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

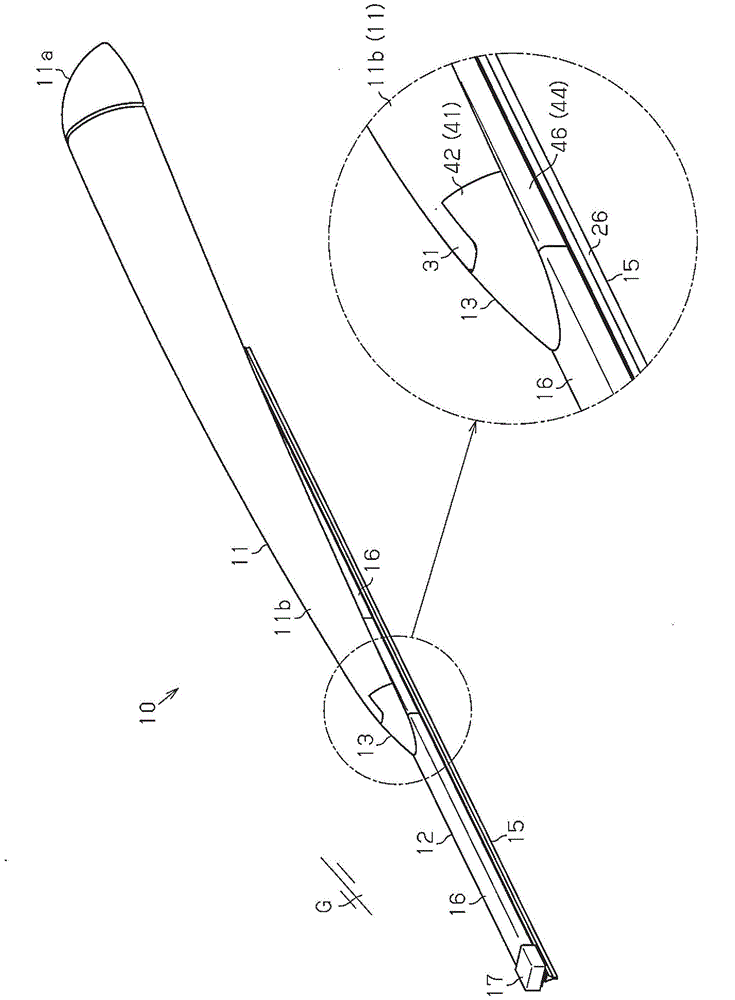

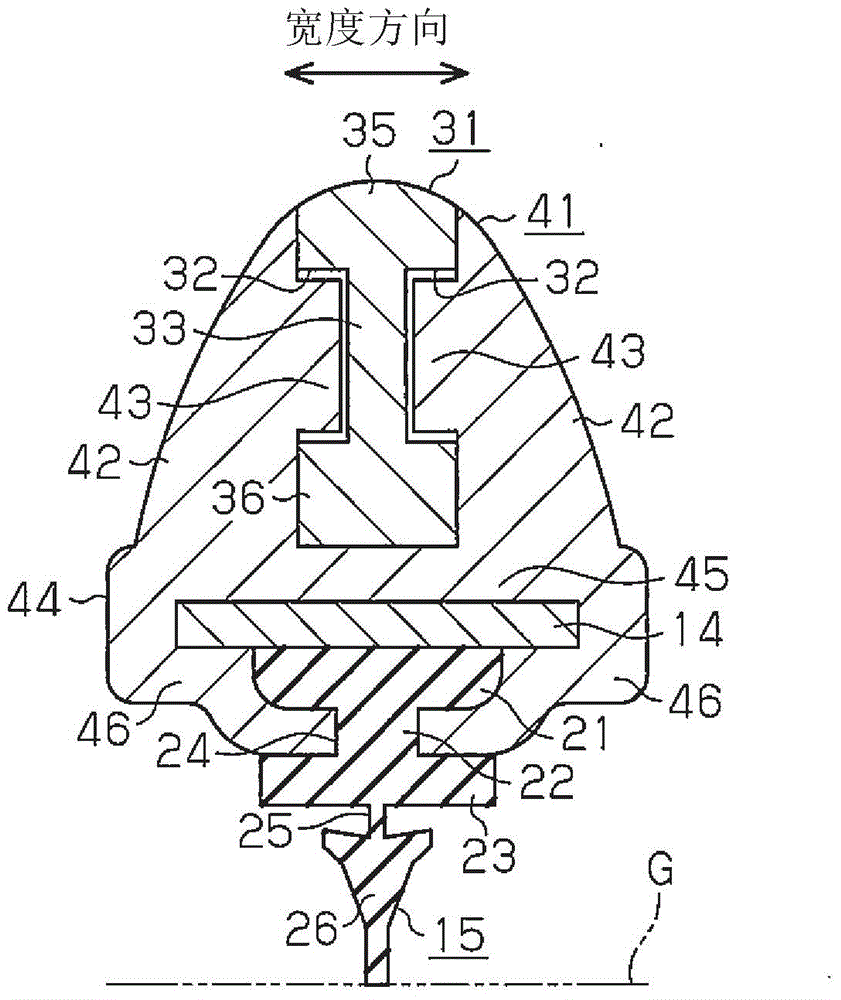

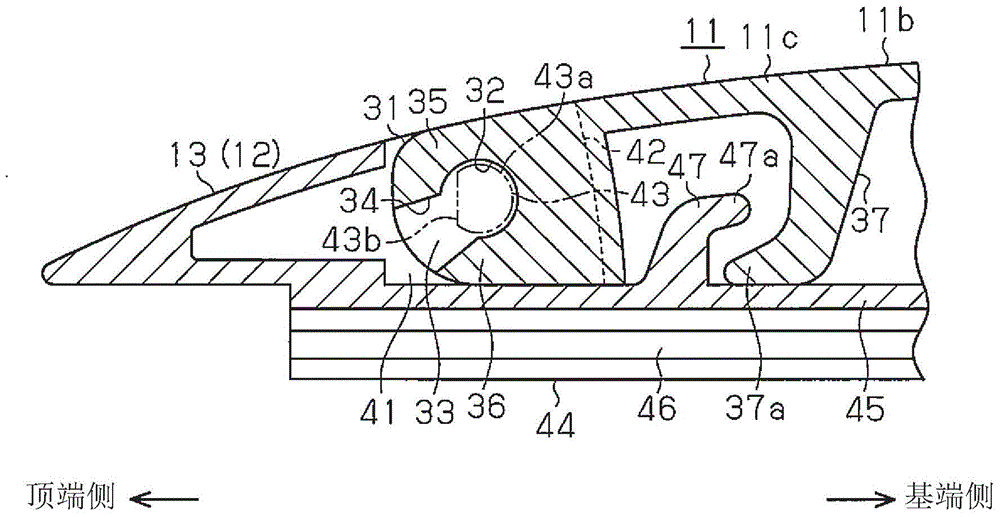

[0034] One embodiment of a vehicle wiper will be described below.

[0035] like figure 1As shown, the vehicle wiper blade 10 of this embodiment is used to wipe off raindrops and the like adhering to the surface (wiping surface G) of the rear glass of the vehicle. The vehicle wiper 10 is composed of a resin wiper arm 11 and a wiper blade 12 which is rotatably connected to the tip end of the wiper arm 11 and is arranged in contact with a wiper surface. on G.

[0036] A base end portion of the wiper arm 11 is connected to an arm head 11 a fixed to a pivot shaft not shown. The wiper arm 11 and the wiper blade 12 move back and forth based on the above-mentioned pivot shaft being rotationally driven by a wiper motor (not shown). Then, wiping on the wiping surface G is performed by the swinging wiper blade 12 . In addition, a spring (not shown) for generating a pressing force for pressing the wiper blade 12 against the wiping surface G is attached to the wiper arm 11 .

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com