Linear motor

A linear motor and magnetic technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems such as the difficulty in realizing the miniaturization and space saving of the linear motor, the increase in the weight of the linear motor module, and the troublesome assembly work, etc., and achieve low cost. The effect of simplification, simple manufacturing and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0063] [Structure of Linear Motor]

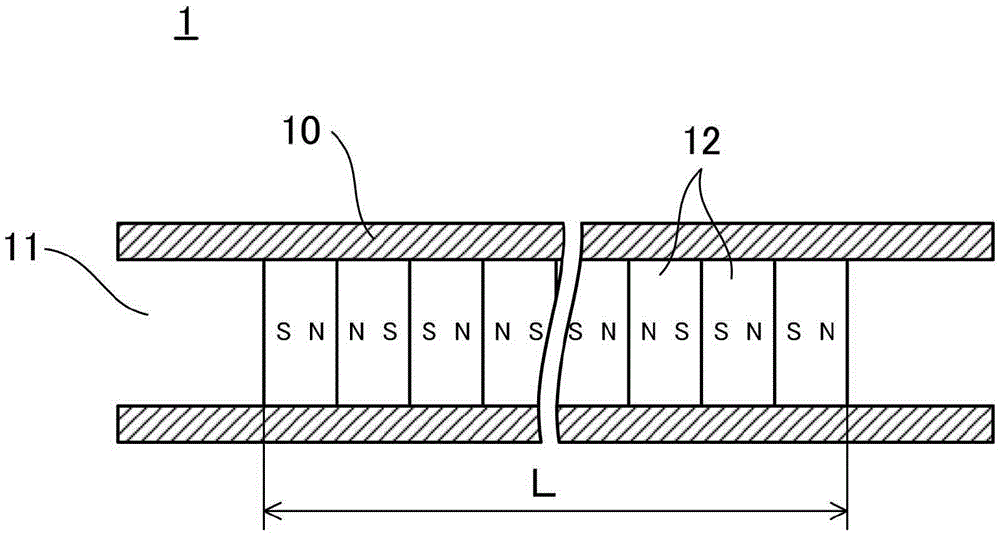

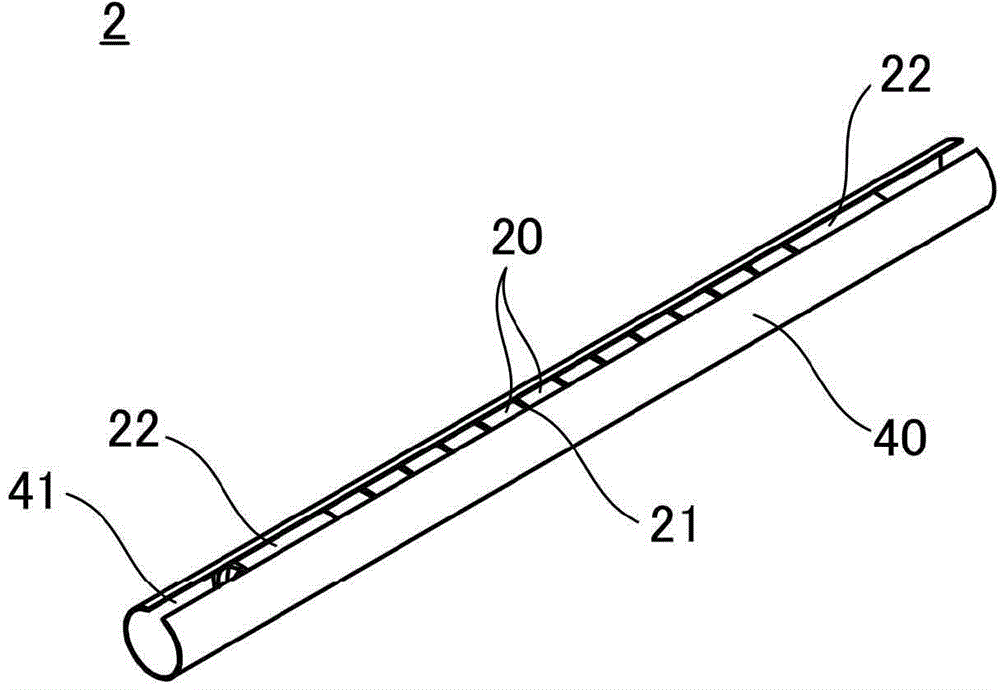

[0064] refer to Figure 1 to Figure 9 , the configuration of the linear motor according to Embodiment 1 will be described. figure 1 It is a perspective view of the linear motor of Embodiment 1. figure 2 It is a sectional view of the field part in the linear motor of Embodiment 1. image 3 It is a perspective view of the armature in the linear motor of Embodiment 1. Figure 4 It is a perspective view of the first form of the frame in the linear motor of Embodiment 1. Figure 5 It is the front view of the frame open state in the linear motor of Embodiment 1. Figure 6 It is a perspective view of the second form of the frame in the linear motor of Embodiment 1. Figure 7 It is a perspective view of the third form of the frame in the linear motor of Embodiment 1. Figure 8 It is the perspective view of the 4th form of the frame in the linear motor of Embodiment 1. Figure 9 It is a front view of the linear motor of Embodiment 1.

[006...

Embodiment approach 2

[0112] Next, refer to Figure 10 ~ Figure 14 , the linear motor 200 according to Embodiment 2 will be described. Figure 10 It is a perspective view of the linear motor of Embodiment 2. Figure 11 It is a perspective view of the second form of the armature in the linear motor of Embodiment 2. Figure 12 It is a perspective view of the third form of the armature in the linear motor of Embodiment 2. Figure 13 It is a perspective view of the fifth form of the frame in the linear motor of Embodiment 2. Figure 14 It is a perspective view of the sixth form of the frame in the linear motor of Embodiment 2. In addition, the same code|symbol is attached|subjected to the same component as the linear motor 100 of Embodiment 1, and the description is abbreviate|omitted.

[0113] Such as Figure 10 As shown, the linear motor 200 of the second embodiment is the same as that of the first embodiment except that the structures of the magnetic cylinder 40 of the armature 2 and the frame ...

no. 3 approach 〕

[0136] Next, refer to Figure 15 , the linear motor unit 300 according to Embodiment 3 will be described. Figure 15 It is a perspective view of the linear motor unit of Embodiment 3. In addition, the same code|symbol is attached|subjected to the same component as the linear motor 100 of Embodiment 1, and the description is abbreviate|omitted.

[0137] Such as Figure 15 As shown, the linear motor unit 300 of the third embodiment is a linear motor formed by arranging a plurality of the linear motors 100 of the first embodiment in the width direction (the beam direction) and forming a unit.

[0138] Screw holes 82 for fastening bolts 81 are formed at both end portions of the upper frame 31 and the lower frame 32 as in the first embodiment. A plurality of linear motors 100 are arranged in contact with each other in the width direction, and sealing plates 80 are arranged at both ends in the width direction. Further, the plurality of linear motors 100 are integrated into a mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com