Deep plate loading test device

A technology of deep plate load and test device, which is applied in the test of basic structure, construction, basic structure engineering, etc. It can solve the problems of instability, difficult reaction force to meet the test requirements, too long force transmission column, etc., and achieve high accuracy , good promotion and application value, and large loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred modes of the present invention will be further described in detail below in conjunction with the accompanying drawings.

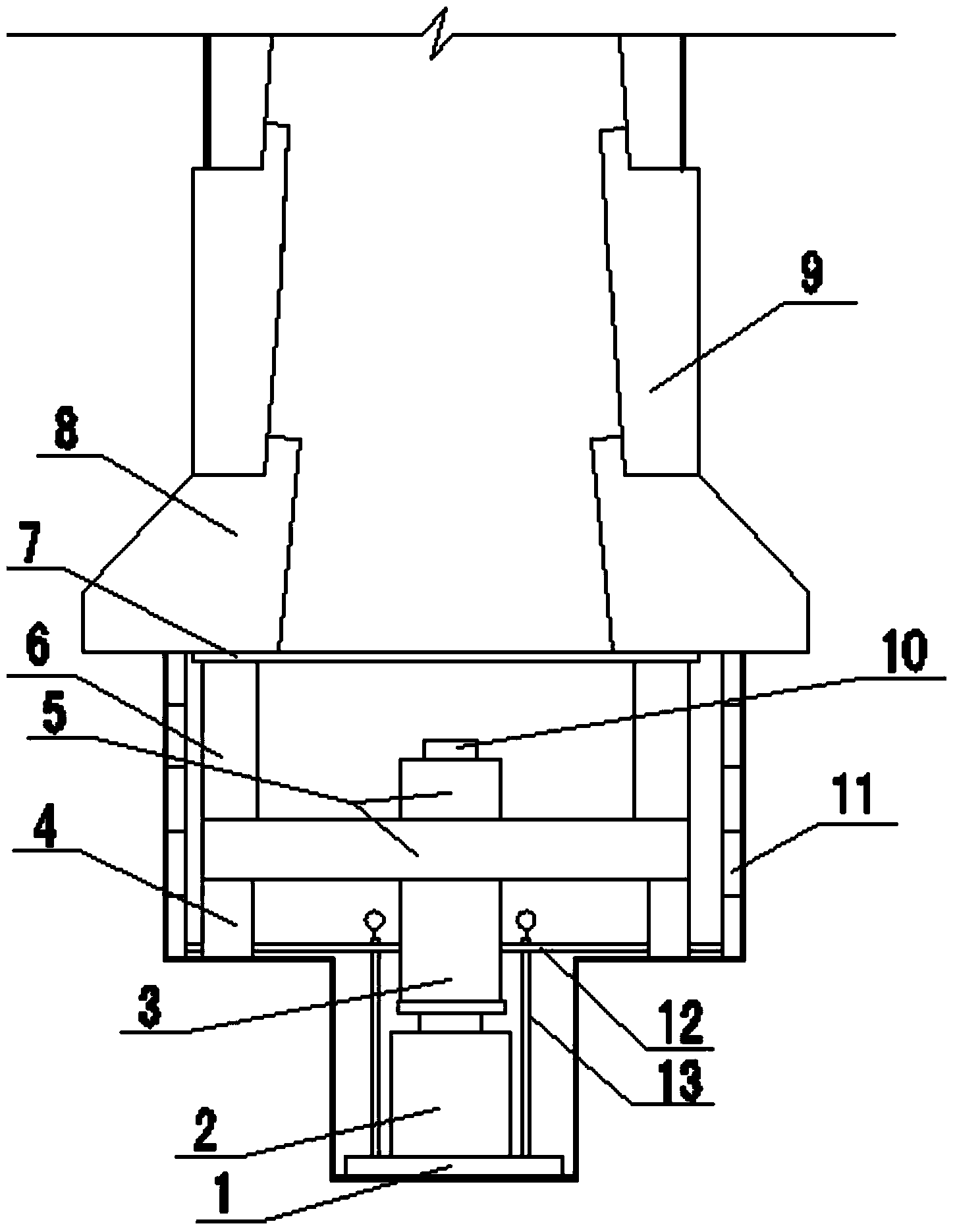

[0024] see figure 1 , the composition of the deep plate load test device is as follows:

[0025] The center of the bearing plate 1 is provided with a jack 2 and a force transmission column 3 successively, and a reference beam 12 is placed outside the force transmission column 3 in a non-contact manner.

[0026] On the same horizontal plane of the benchmark beam 12, there are successively a support 4, a main beam 5, a secondary beam 6, a backing plate 7, a concrete ring beam 8 and a concrete retaining wall 9 on the pile side; wherein, the main beam 5 is cross-shaped, and consists of two cross-stacked The lower surface at the center is connected with the upper surface of the force transmission column 3 in conflict, and the upper surface is equipped with a camera 10 aimed at the dial of the concrete ring beam 8, the dial indicator 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com