Secondary high-pressure grouting expansion bit anchor rod and construction method thereof

A technology of secondary grouting and enlarged head, which is used in infrastructure engineering, construction, sheet pile walls, etc. The end is not dense and other problems, to achieve the effect of large pull-out force, large pull-out force, and small displacement after tensioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

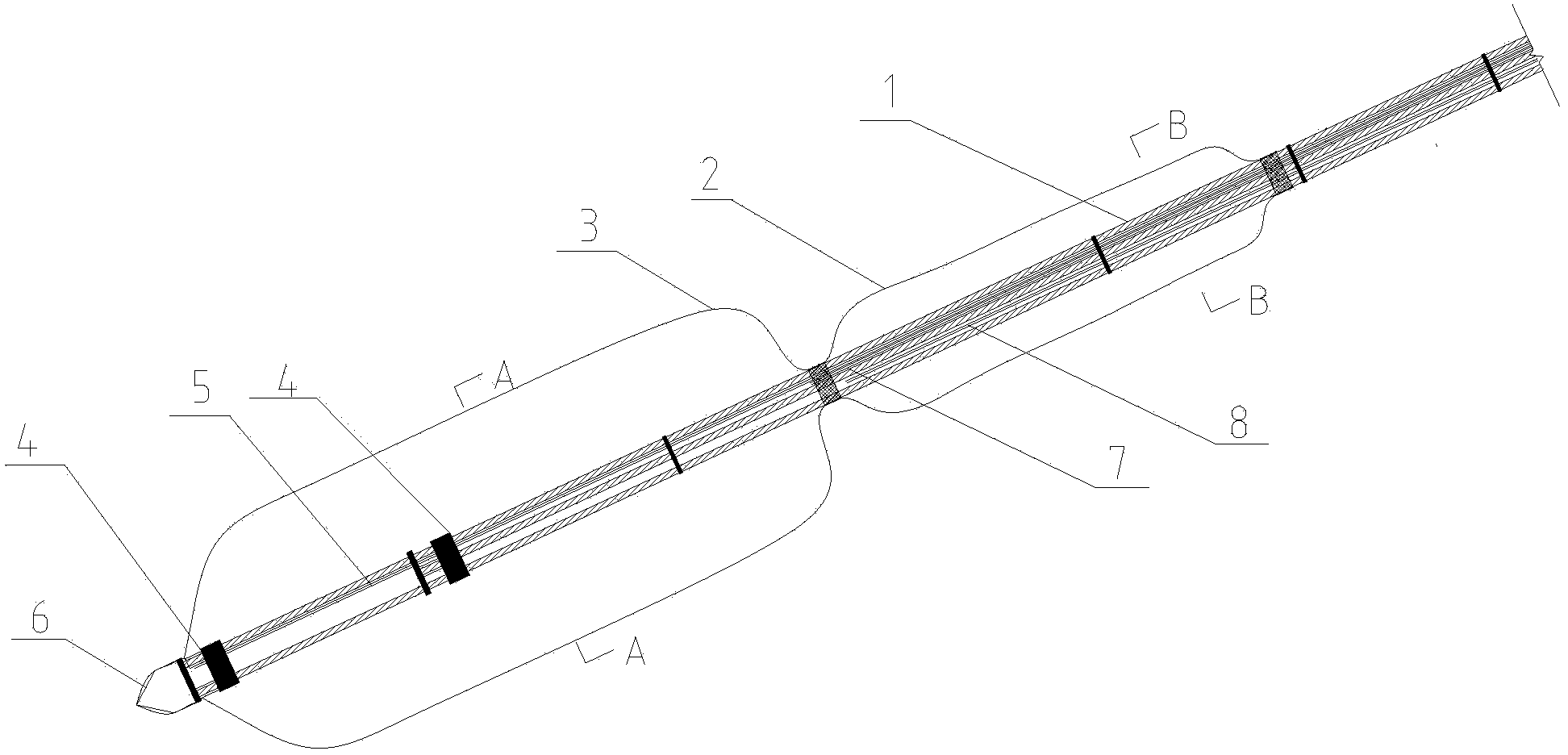

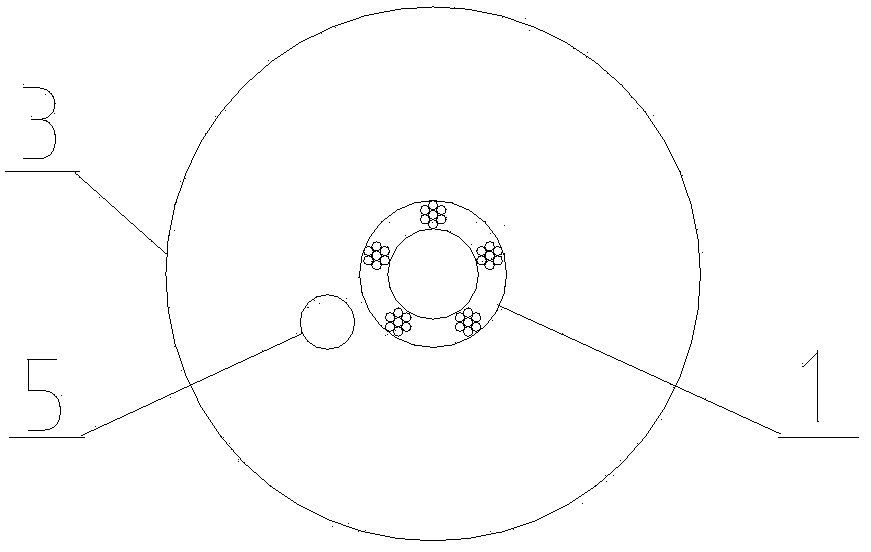

[0025] see Figure 1 to Figure 6 , the present invention includes a bolt body 1, a grouting bag and a grouting pipe, 2 to 3 P anchors 4 are set on the bolt body 1, and a guide cap 6 is installed at the front end of the bolt body to form a pressure dispersion type non-bonding bolt rod body. The key technology is that the centering grouting bag 3 is provided in the front section of the anchor rod body 1, the secondary grouting bag 2 is provided in the rear section of the anchor rod body 1, and the primary grouting pipe 5 and the secondary grouting pipe are arranged on the anchor rod body. 8. The outlet of the primary grouting pipe 5 is located at the front end of the anchor rod body in the centering grouting bag 3 , and the outlet of the secondary grouting pipe 8 is located at the front end of the secondary grouting bag 2 .

[0026] The P anchor 4 is located in the centering grouting bag 3 .

[0027] An exhaust pipe 7 is arranged on the body of the anchor rod, and the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com