Microgel stabilizer with sustained release performance and preparation method thereof

A slow-release performance, microgel technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as long stabilization time, and achieve the effect of inhibiting thermal oxidation chain scission reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

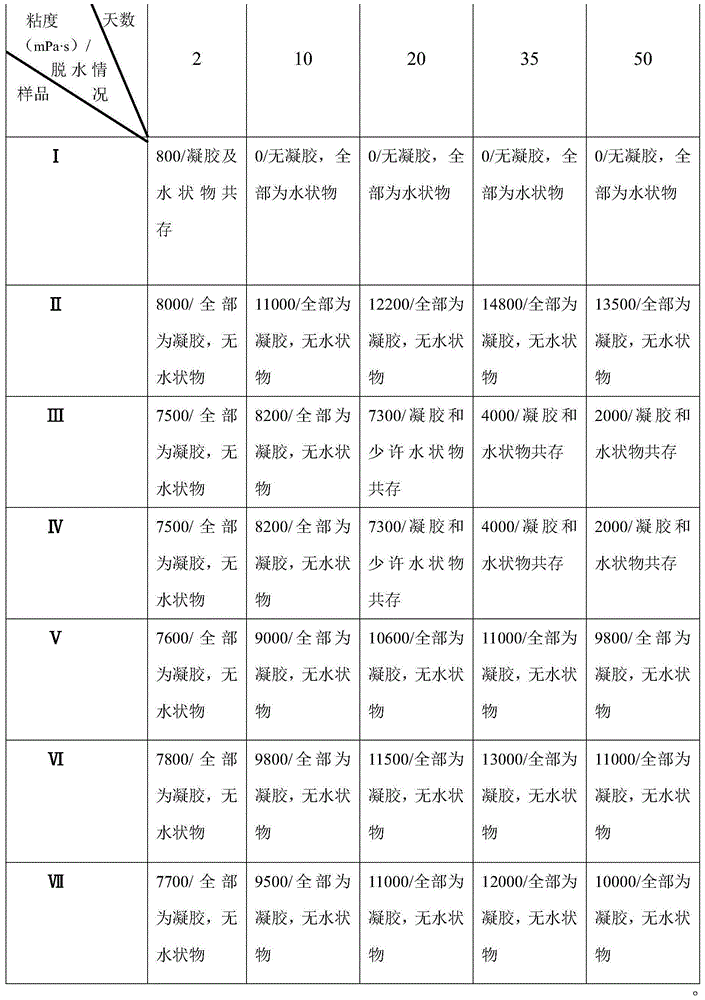

Examples

Embodiment 1

[0030] Add sodium thiosulfate (1.5g), formaldehyde (2.5g), urea (6g), and polyethylene glycol 400 (14g) into water (350g) in sequence, and stir for 60 minutes to mix the compounds uniformly to form solution A .

[0031] Add aluminum nitrate nonahydrate (2.6g) and magnesium nitrate hexahydrate (4.4g) into water (90g) from which carbon dioxide has been removed to form a mixed solution. While stirring the mixed solution, use 5wt% NaOH to adjust the pH to 10.0, and place the mixed solution at 70°C , and reacted for 2 hours under nitrogen protection to form a mixed solution B.

[0032] The solution A and the mixed solution B were mixed evenly in a weight ratio of 1:1, placed at 90° C., stirred and reacted for 4 hours, and the mixed solution C was obtained. The mixed solution C was centrifuged at 5000 rpm for 10 minutes, the solid particles in the mixed solution were discarded, and the remaining colloidal liquid was left for use.

Embodiment 2

[0034] Add sodium thiosulfate (2.3g), formaldehyde (2.1g), urea (7.5g), and polyethylene glycol 800 (16g) into water (650g) in sequence, and stir for 45 minutes to mix the compounds uniformly to form a solution a.

[0035] Add aluminum nitrate nonahydrate (2.75g) and magnesium nitrate hexahydrate (4.1g) into water (55g) from which carbon dioxide has been removed to form a mixed solution. While stirring the mixed solution, use 10wt% NaOH to adjust the pH to 8.5, and place the mixed solution at 80°C , and reacted for 10 hours under the protection of nitrogen to form a mixed solution B.

[0036]The solution A and the mixed solution B were mixed uniformly at a weight ratio of 2:1, placed at 60°C, stirred and reacted for 2.8 hours, and the mixed solution C was obtained. The mixed solution C was centrifuged at 3000 rpm for 10 minutes, the solid particles in the mixed solution were discarded, and the remaining colloidal liquid was left for use.

Embodiment 3

[0038] Add sodium thiosulfate (3.2g), formaldehyde (1.8g), urea (9g), and polyethylene glycol 600 (17g) into water (about 500g) in sequence, and stir for 30 minutes to mix the compounds uniformly to form a solution a.

[0039] Add aluminum nitrate nonahydrate (2.91g) and magnesium nitrate hexahydrate (3.85g) into water (60g) from which carbon dioxide has been removed to form a mixed solution. While stirring the mixed solution, use 15wt% NaOH to adjust the pH to 9.0, and place the mixed solution at 90°C , and reacted for 20 hours under the protection of nitrogen to form a mixed liquid B.

[0040] The solution A and the mixed solution B were mixed uniformly in a weight ratio of 3:1, placed at 70° C., stirred and reacted for 3 hours, and the mixed solution C was obtained. The mixed solution C was centrifuged at 3500 rpm for 10 minutes, the solid particle precipitation in the mixed solution was discarded, and the remaining colloidal liquid was left for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com