Bag making machine longitudinal sealing device with integrated movable and static hot press plates

A technology of static ironing press and dynamic ironing press, which is applied in the direction of container manufacturing machinery, rigid/semi-rigid container manufacturing, packaging, etc., and can solve the problems affecting the hot pressing of packaging bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

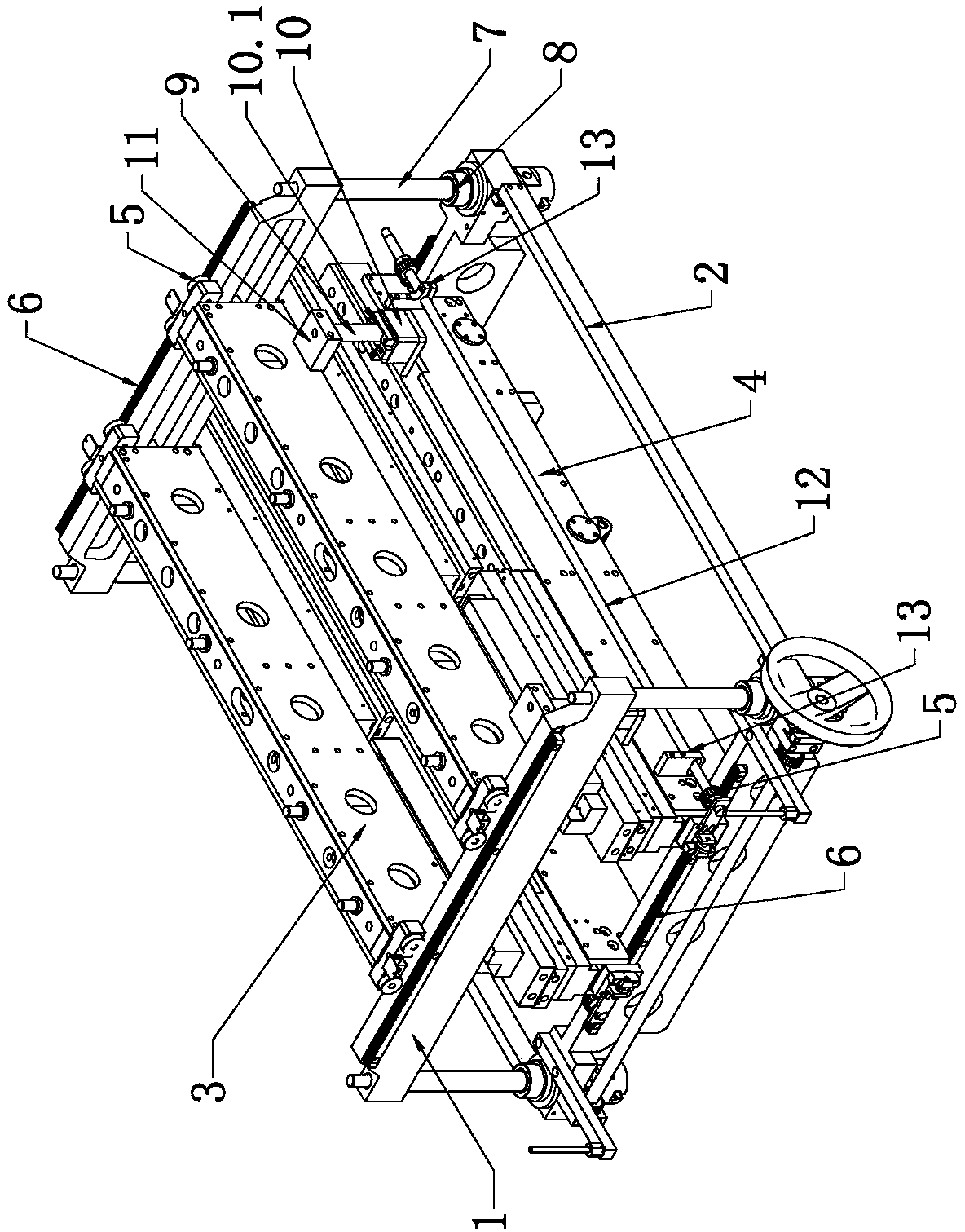

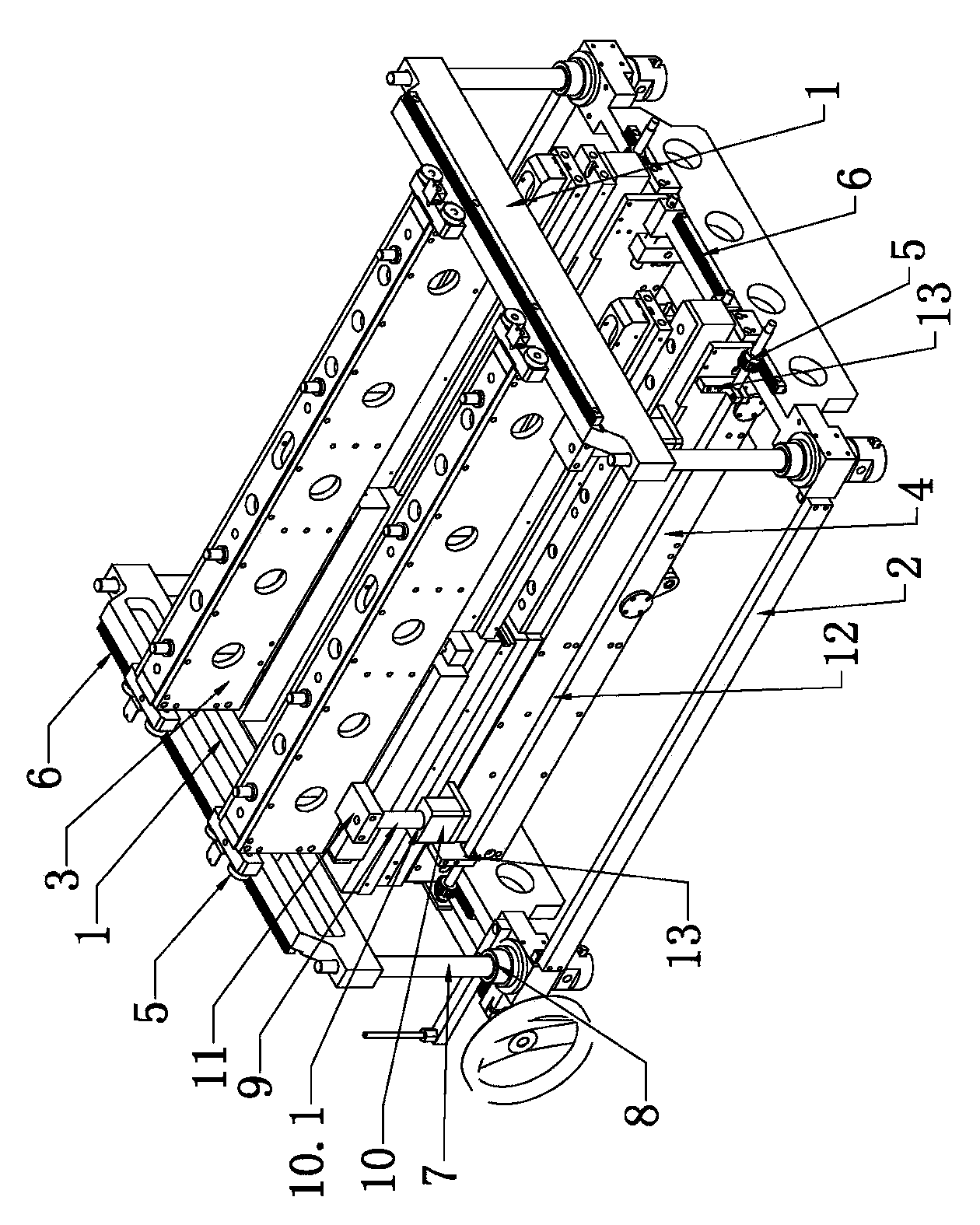

[0008] Such as figure 1 and figure 2 As shown, a bag making machine longitudinal sealing device with integrated dynamic and static ironing platen, including upper frame 1, lower frame 2, dynamic ironing platen 3, static ironing platen 4, rolling gear 5, rack 6, machine Frame guide post 7, spring 8, gear rod 12, gear rod fixed block 13; rack 6 is provided at both ends of upper frame 1 and lower frame 2, and gear rod 12 is connected to static ironing platen 4 through gear rod fixed block 13 Above, the two ends of the gear rod 12 are connected with rolling gears 5, and the two ends of the dynamic ironing platen 3 are connected with rolling gears 5; several static ironing platens 4 are installed on the racks 6 at both ends of the lower frame 2 through the rolling gears 5 at both ends. The four jiaos of lower frame 2 are respectively provided with a frame guide column 7, and upper frame 1 is arranged on the frame guide column 7 and is above lower frame 2, the frame between upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com