Separated straight groove vibrating method and device

A vibrating device and a separation-type technology are applied in the field of separation-type straight groove vibration methods and devices, which can solve problems such as increasing production costs, increasing product breakage rates, and mutual collision of workpieces, thereby reducing losses, avoiding workpiece collisions, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

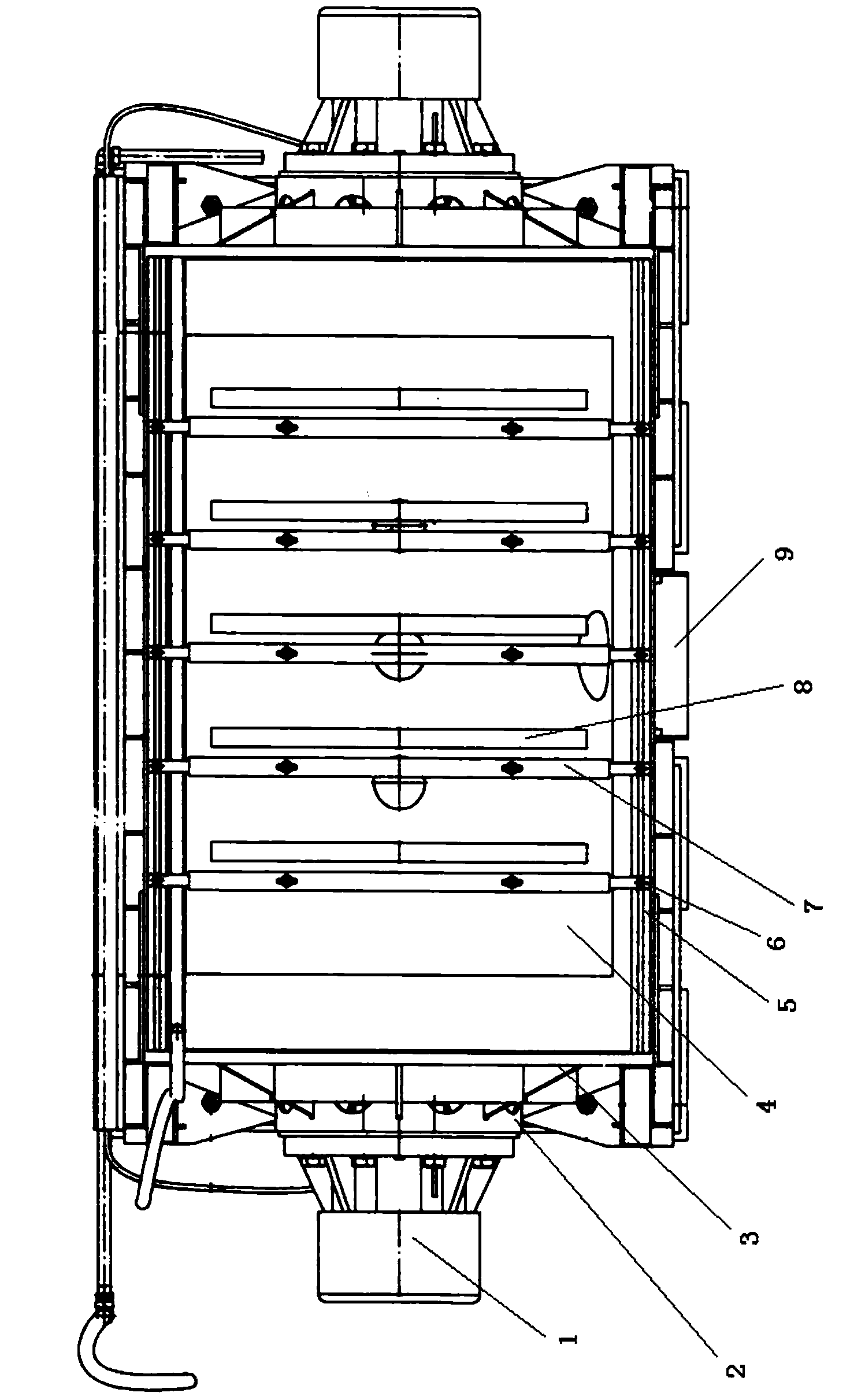

[0013] Example. The divided straight groove vibration method is characterized in that: by installing 5-7 movable partitions in the rectangular tank, the workpiece is placed between the two partitions for vibration processing; the two ends of the partition are The screw is fixed in the concave guide rail, and the nut connecting the screw cannot rotate in the rail. The nuts are square nuts.

[0014] Realize the separated type straight groove vibrating device of above-mentioned method, constitute as figure 1 As shown, including a base 2, a container 3 is provided on the base 2 via a plurality of vibrating springs, a vibration motor 1 is provided at both ends of the container 3, and the inside of the container 3 is a rectangular tank body 4, and the two sides of the rectangular tank body 4 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com