Virtual robot and real robot integration based picking system and method

A virtual robot and virtual system technology, applied in the direction of picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of low picking success rate and low visual positioning accuracy, and achieve the effect of reducing development costs and speeding up the development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

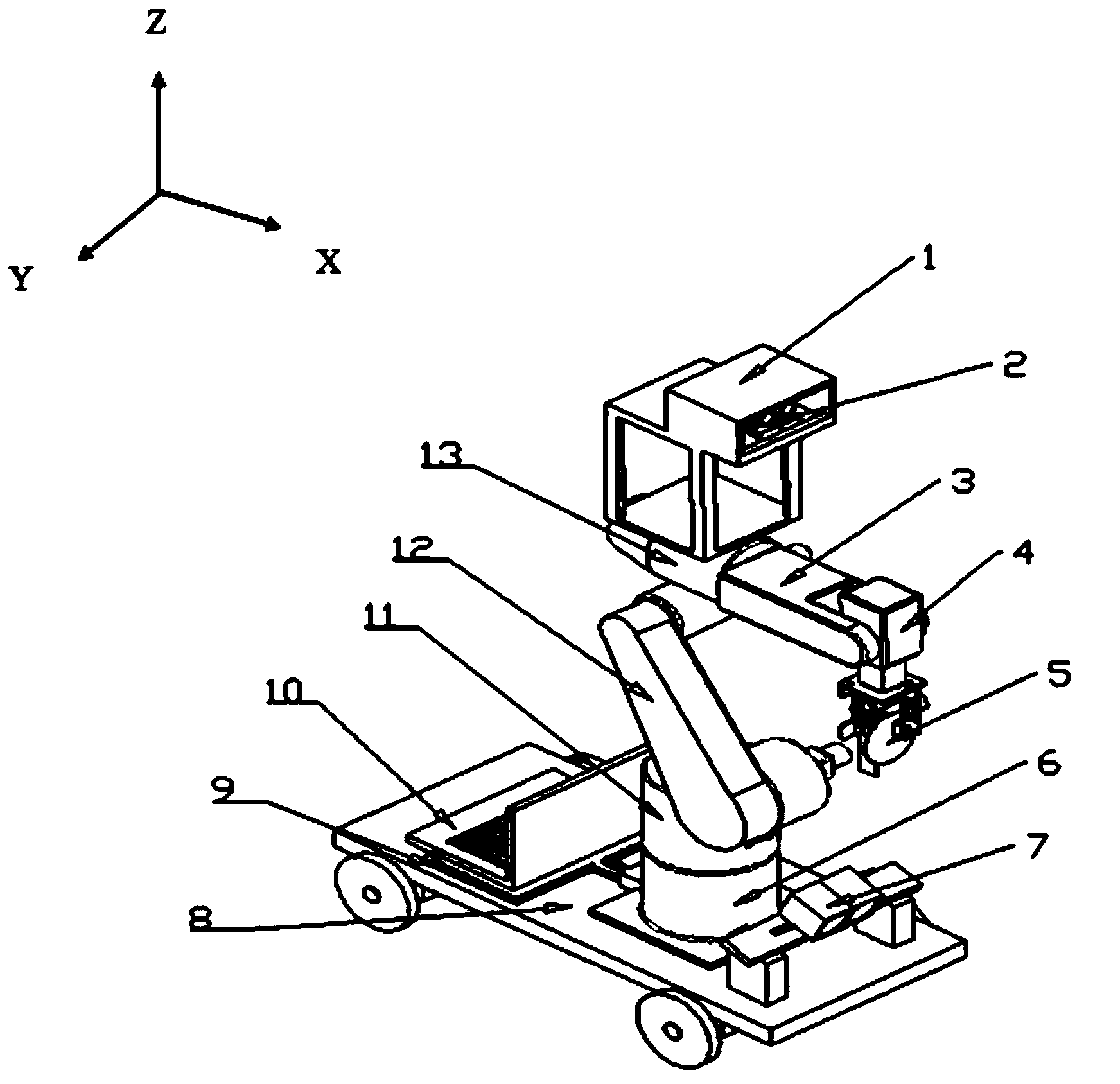

[0028] Such as figure 1 , the picking system based on the integration of virtual robot and real robot includes two parts: real robot and virtual robot picking simulation system. These two parts perform real-time data communication and feedback, and the two assist and correct each other. The real robot positioning vision system includes a consignment car 8, a binocular camera 2, a robot and its manipulator, and a visual positioning software system located in a computer 10. The manipulator of the robot includes a base 6 , a joint one 11 , a joint two 12 , a joint three 13 , a joint 4 , and an end effector 5 . Wherein, the robot base 6 is fixedly connected with the consignment trolley, and the robot is a 6-DOF robot. The binocular camera positioning system is developed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com