Novel in-out equal potential working method

An equipotential and new technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing economic investment, increasing manpower consumption, and consuming physical strength of personnel, so as to improve safety, reduce manpower consumption, and ensure reasonable utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

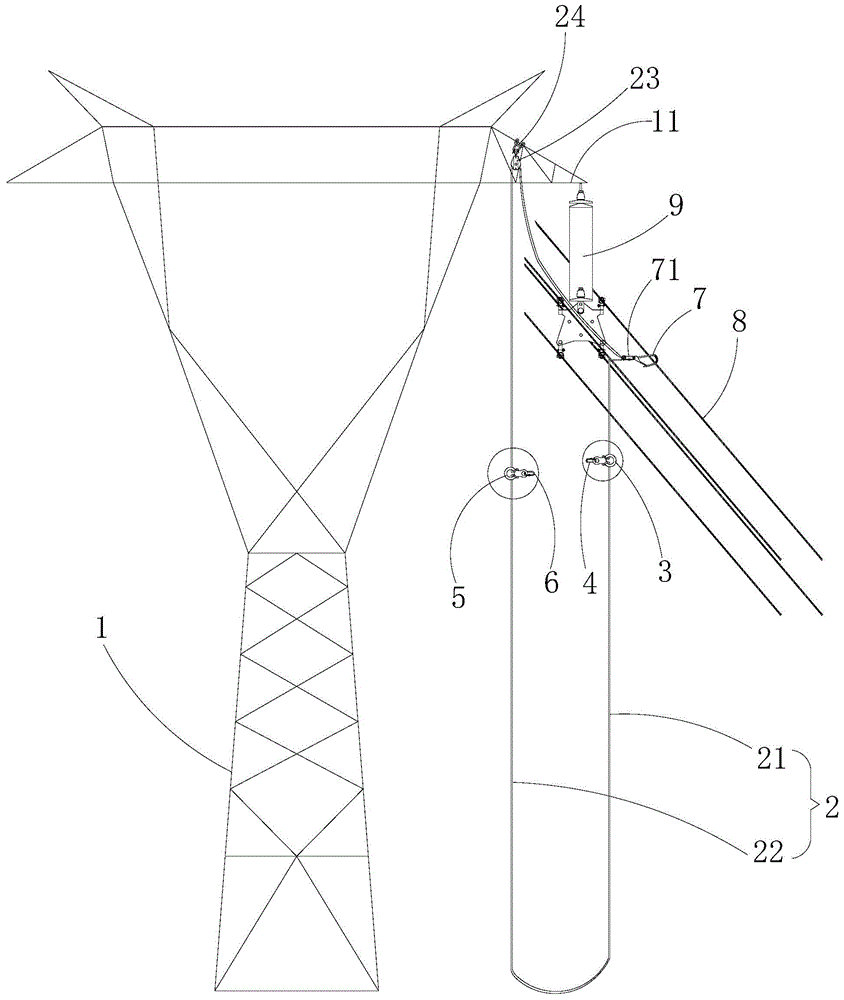

[0030] 1. The equipotential electrician enters the equipotential, which includes the following steps:

[0031] Step 1. The ground potential electrician and the equipotential electrician carry the transmission rope 2 passing through the insulating pulley 23 to the iron tower cross arm 11 along the foot nails of the iron tower 1, and the transmission rope 2 is a ring-shaped hook.

[0032] Step 2. Fix the insulating pulley 23 to the iron tower cross arm 11 through the endless rope sleeve 24, and the transfer rope 2 extends downward. The transmission rope 2 on the side is defined as the transmission rope 22. No matter how the transmission rope 2 slides on the insulating pulley 23, the transmission rope 21 and the transmission rope 22 are defined according to the above method, that is, the positions of the transmission rope 21 and the transmission rope 22 are defined. is changing.

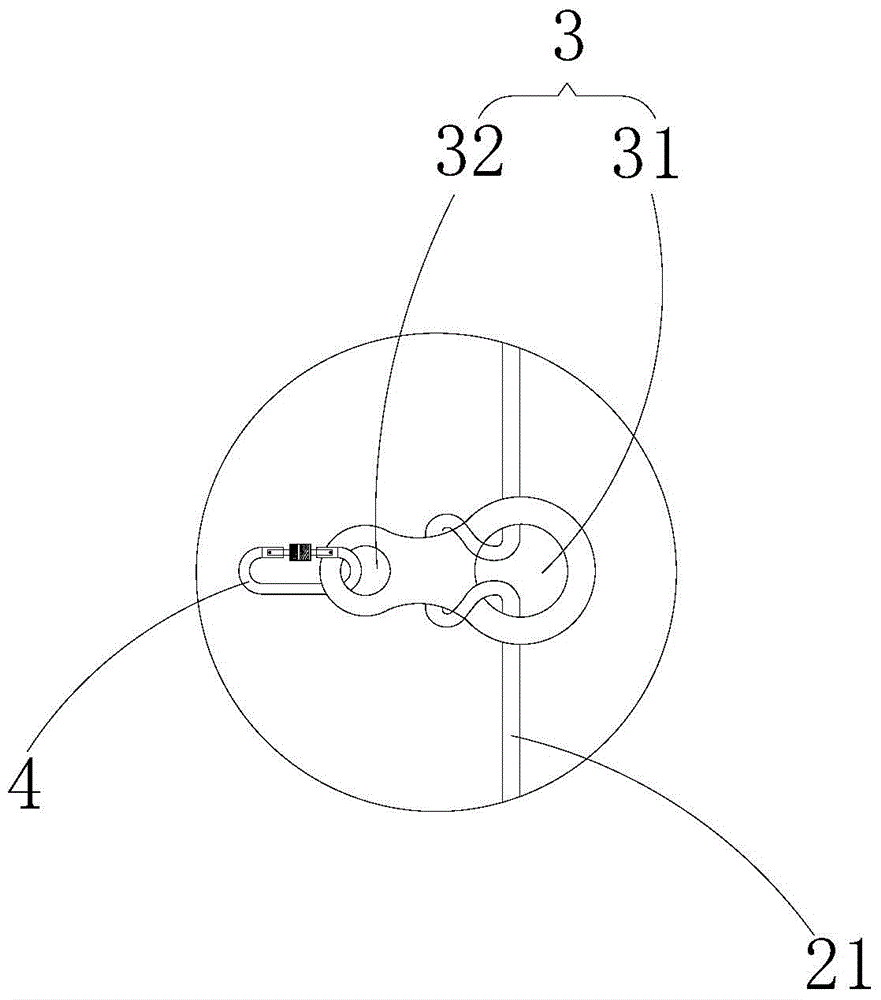

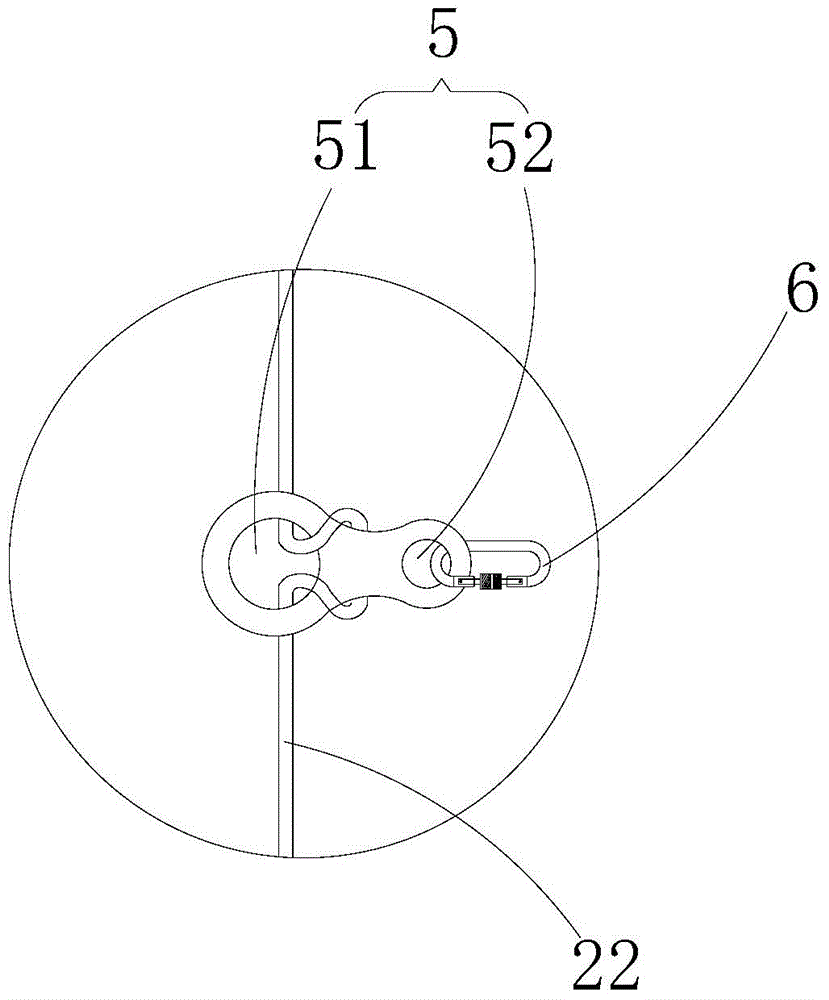

[0033] Step 3. Tie a first double bar tack on the transmission rope 21, pass a first thread main lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com