Organic light-emitting display device

A light-emitting display and organic light-emitting layer technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of current magnitude difference, unfavorable light emission of organic light-emitting elements, and inconsistent display brightness of display areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

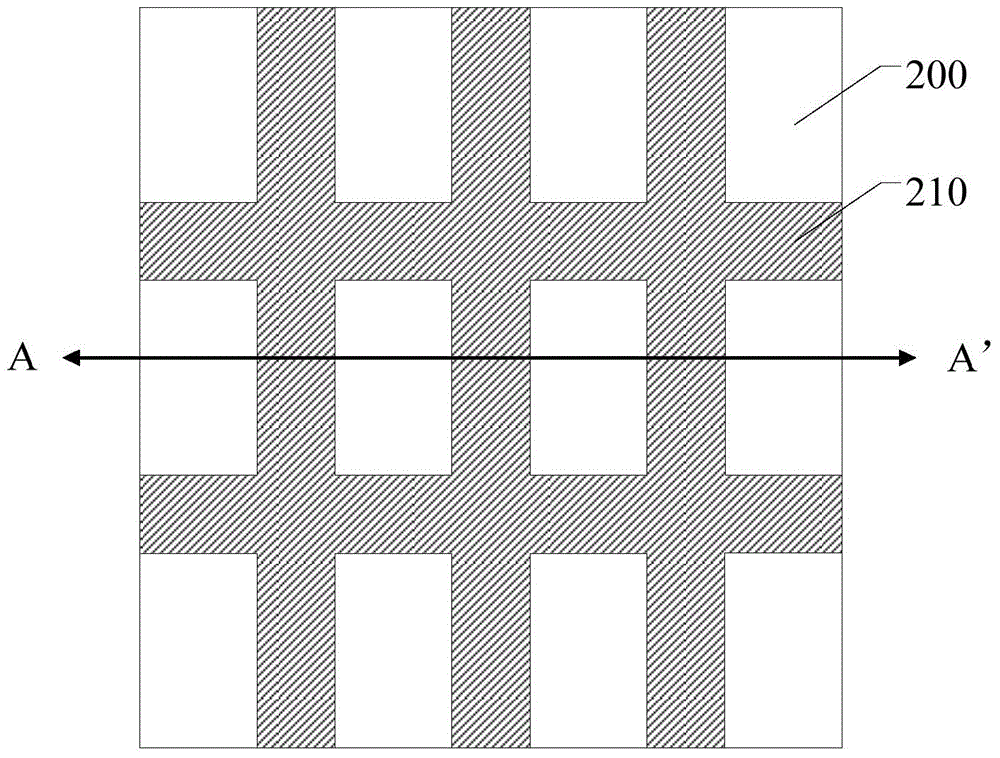

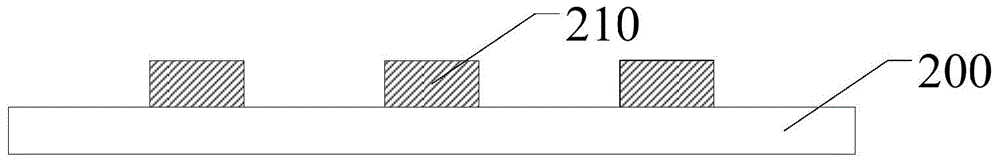

[0021] Please refer to figure 1 , figure 1 It is a schematic top view of the cover plate of the organic light-emitting display device provided in Embodiment 1 of the present invention, figure 2 for figure 1 A cross-sectional view of the cover plate in AA' direction, the cover plate includes a second substrate 200 and a conductive layer 210, and the conductive layer 210 is disposed on the side of the second substrate 200 facing the first substrate.

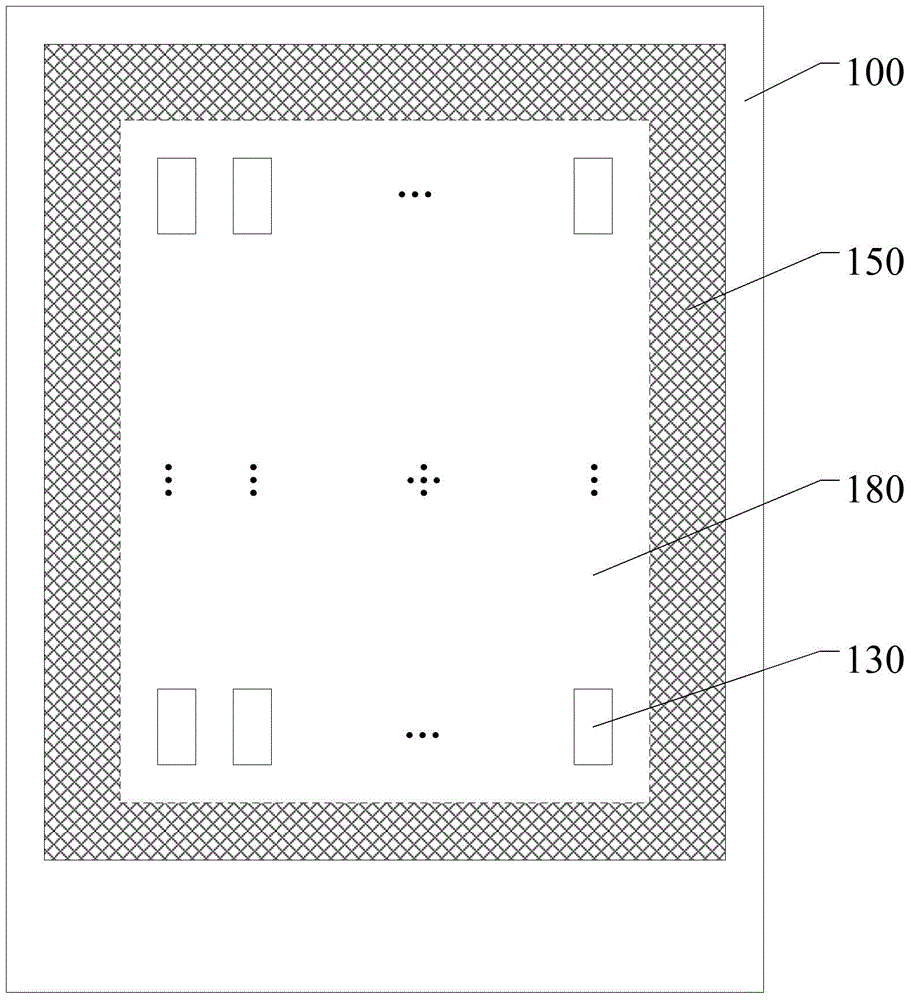

[0022] image 3 It is a top view schematic diagram of an array substrate of an organic light emitting display device provided in Embodiment 1 of the present invention. The array substrate and the cover plate are arranged opposite to each other. The array substrate includes a first substrate 100, a plurality of organic light emitting elements 130 and cathode via holes 150. The plurality of organic light emitting elements 130 and cathode vias 150 are disposed on the side of the first substrate 100 facing the second substrate 200 ...

Embodiment 2

[0030] refer to Figure 7 and Figure 8 , Figure 7 It is a top view schematic diagram of the cover plate of the organic light emitting display device provided in the second embodiment, Figure 8 for Figure 7 Sectional view of the middle cover along the direction of BB'. The organic light-emitting display device provided in the second embodiment is based on the first embodiment, and the thickness of the conductive layer 310 corresponding to different positions of the display area is different, and the variation trend of the thickness is related to the position of the cathode via hole.

[0031] Figure 7 and Figure 8 shows the case where the cathode vias are around the display area, Figure 7 Among them, the area shown in area 350 is the area corresponding to the cathode via hole. Specifically, when the array substrate and the cover plate are arranged oppositely, the area 350 corresponding to the cathode via hole corresponds to the area of the cathode via hole in the ...

Embodiment 3

[0038] refer to Figure 9 , Figure 9 It is a schematic plan view of a cover plate of an organic light emitting display device provided in Embodiment 3 of the present invention. The thickness of the conductive layer 410 of the organic light-emitting display device provided in Embodiment 3 is the same, but the arrangement density of the conductive layer 410 at different positions in the display area is changed, and the distribution density of the conductive layer 410 on the cover plate in the display area is not uniform, and the change trend is It is related to the position of the cathode via.

[0039] Figure 9 shows the case where the cathode vias are around the display area, Figure 9 Among them, the area 450 is the area corresponding to the cathode via hole. Specifically, when the array substrate and the cover plate are arranged oppositely, the area 450 corresponding to the cathode via hole corresponds to the cathode via hole area of the array substrate, and is the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com