Glass bottle online inspection system

A detection system and glass bottle technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of fragile glass bottles, increased scrap rate, glass bottle breakage, etc., to reduce the breakage rate and avoid collisions , to avoid the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

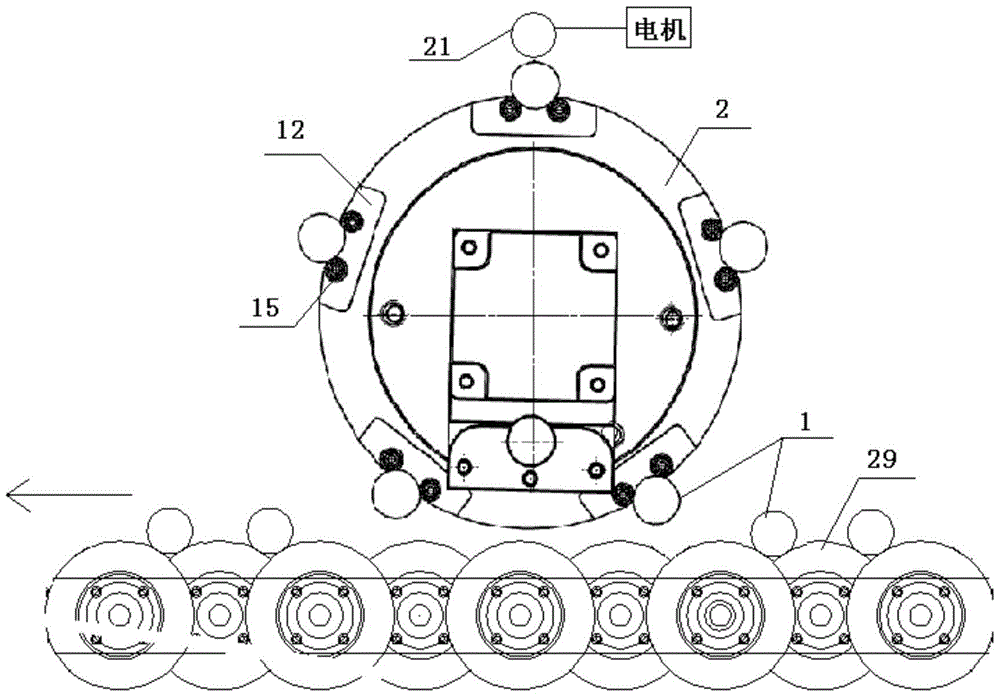

[0036] Such as figure 1 , 2 , 5-8, 10, and 11 shown, the present invention comprises a plurality of detection devices, and detection device is made up of 27 grades of light sources 28 of cameras in pairs, and camera 27 is connected with industrial computer (industrial control computer), and bottle-getting device is positioned at conveying line 29, the bottle-taking device is a turntable-type bottle-taking device, including a servo motor 8 mounted on a frame (not shown in the figure) and a turntable 2 with a plurality of notches 17 on the outer ring, and the turntable 2 is vertical place, its axis of rotation is parallel to the horizontal plane, a bottle holder 12 is installed in the notch 17, and the bottle holder 12 has a groove 18 that matches the glass bottle to be detected. Generally speaking, the groove 18 matches the glass bottle body, and the groove 18 A through hole 13 is provided; along the axial direction of the turntable 2, a pair of bearings 15 are installed at bo...

Embodiment 2

[0038] Such as figure 1 , 3 , 5-11, the turntable type bottle taking device provided by the present invention also includes a first disk 5, the first disk 5 is installed on the bearing seat 7, and the transmission shaft 4 passes through the first disk 5 and passes through the bearing Seat 7 is installed on the frame. The back side of the turntable 2 (that is, the surface attached to the first disc 5) has a coaxial annular protrusion 3, and a plurality of circular holes 14 are arranged on the annular protrusion, and each circular hole 14 corresponds to a notch 17 , the circular hole communicates with the negative pressure hole 19 on the rotating disk; the outer surface of the first disc 5 is provided with a non-closed ring groove 16 (the so-called non-closed ring groove means that the ring groove is not connected from the beginning to the end, there is a gap, non-closed ring groove There is no groove at the ring place where the closed ring groove is located), and the cavity 2...

Embodiment 3

[0040] Such as figure 1 , 4 , 5-11, the first disc 5 is installed on the second disc 6, the second disc 6 is installed on the bearing seat 7, and the transmission shaft 4 passes through the first disc 5 and the second disc 6 , and installed on the frame through the bearing seat 7. The back side of the turntable 2 (that is, the surface attached to the first disc 5) has a coaxial annular protrusion 3, and a plurality of circular holes 14 are arranged on the annular protrusion, and each circular hole 14 corresponds to a notch 17 , the circular hole communicates with the negative pressure hole 19 on the turntable; the outer surface of the first disc 5 is provided with a non-closed ring groove 16, and the cavity 20 communicates with the non-closed ring groove 16; the non-closed ring groove 16 is attached to On the partial circular hole 14 of the annular protrusion 3 . The turntable 2 is attached to the first disc 5 and can rotate relative to each other, and a cavity 20 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com