Fixed structure of glass ribs

A technology for fixing structures and glass ribs, applied to building components, building structures, walls, etc., can solve the problems of reducing the safety and service life of full glass curtain walls, slow installation speed of glass ribs, deformation of joints, etc., to improve stability Sex and firmness, improving firmness and reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

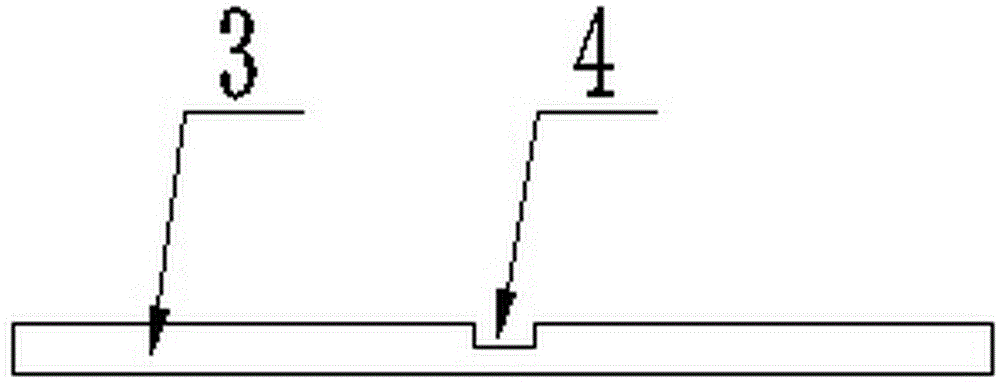

[0024] A fixing structure for a glass rib, comprising a glass rib 1, a connecting screw 2, and two clamps for clamping the glass rib 1, the clamp is composed of two splints 3 cross-welded and fixed in the middle, and the two splints 3 The middle part of each is provided with a groove 4, the depth of the groove 4 is half of the thickness of the splint 3, and the two splints 3 are welded and fixed into one body through the groove 4 in the middle, so that the thickness of the welding place of the two splints 3 is the same as that of any splint 3 The same thickness, when the glass rib 1 is connected, the splint 3 can be closely connected with the glass rib 1; the splint 3 is uniformly provided with a plurality of inclined fixing holes, and the fixing holes are provided with inclined support platforms 6 is used to support the nut of the connecting screw 2, the support platform 6 is provided with a through hole communicating with the fixing hole, the glass rib 1 is provided with an i...

Embodiment 2

[0028] A fixing structure for a glass rib, comprising a glass rib 1, a connecting screw 2, and two clamps for clamping the glass rib 1, the clamp is composed of two splints 3 cross-welded and fixed in the middle, and the two splints 3 There are two symmetrical support rods 5 welded therebetween, the two ends of the support rods 5 are located on the two glass ribs 1 respectively, and the middle parts of the two splints 3 are provided with grooves 4, and the depth of the grooves 4 is as deep as that of the splint 3. Half of the thickness, the two splints 3 are welded and fixed into one body through the groove 4 in the middle, so that the thickness of the welding place of the two splints 3 is the same as that of any splint 3, and when the glass rib 1 is connected, the splint 3 can be connected with the glass rib. 1 are tightly connected together; the splint 3 is evenly provided with a plurality of inclined fixing holes, and the fixed holes are provided with an inclined support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com