Silkworm cocoon purification and dehumidification equipment

A silkworm cocoon and equipment technology, applied in the field of silkworm cocoon processing equipment, can solve the problems of difficult control of missed detection rate and low work efficiency, and achieve the effects of reducing labor force, improving work efficiency and high impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

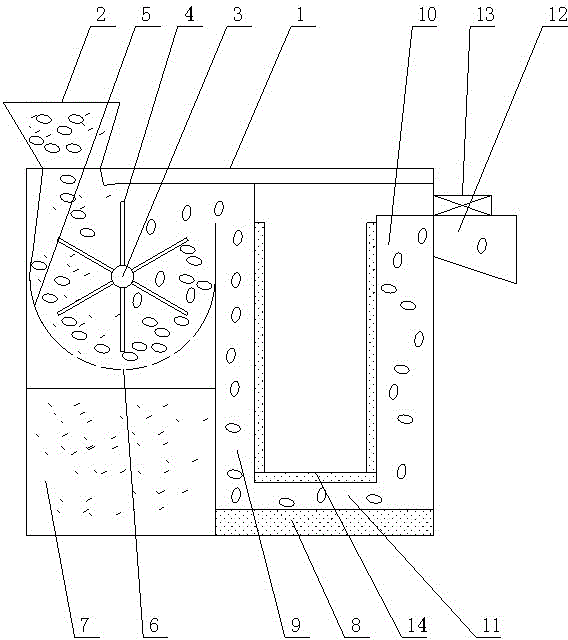

[0015] Such as figure 1 As shown, a cocoon removal and dehumidification device of the present invention includes a box body 1, a cocoon inlet 2 is provided on the top side of the box body 1, and a diversion and removal component and a dehumidification channel are arranged inside the box body 1, and the diversion and removal The miscellaneous components include the diversion and impurity removal roller 3, the pusher plate 4 and the outer circular guide plate 5, the pusher plate 4 is arranged on the periphery of the diversion and impurity removal roller 3 at equal angles, and the diversion and impurity removal roller 3 drives the pusher plate 4 to be arranged outside The inside of the circular guide plate 5 runs counterclockwise, the top of the outer circular guide plate 5 is connected to the cocoon opening 2, the bottom of the outer circular guide plate 5 is provided with a miscellaneous outlet 6, and the bottom of the outer circular guide plate 5 is provided with a miscellaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com