A control method for automatic adjustment of copper strip pickling line

An automatic adjustment and control method technology, applied in the field of strip production and processing, can solve problems such as high labor intensity, time-consuming, and small flat wire coil weight, and achieve the effects of reducing operating stations, saving labor costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments.

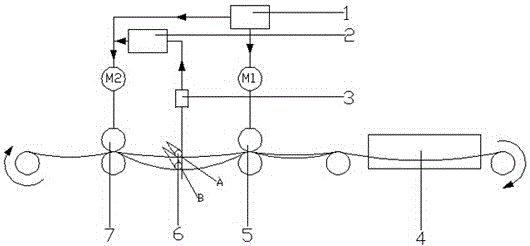

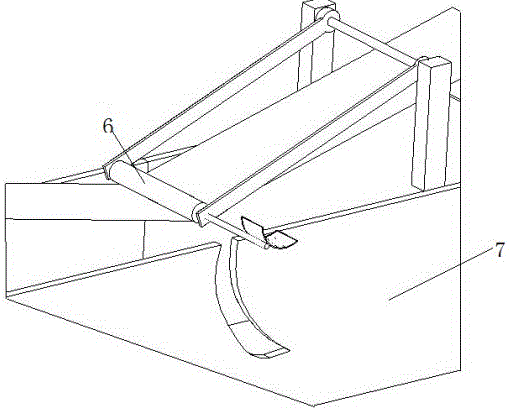

[0017] Such as figure 1 , figure 2 As shown, an automatic adjustment copper strip pickling line includes an unwinding machine, a water brush machine 7, a passivation machine 5, a drying furnace 4 and a winding machine; the first frequency converter 1 is installed on the passivation machine 5 ; The distance detection sensor 3 is provided between the water brush machine 7 and the passivation machine 5, and the distance detection sensor 3 is connected with the second frequency converter 2; the first frequency converter 1 and the second frequency converter 2 are all connected to the water The brush machine 7 is connected; the outlet of the water brush machine 7 is equipped with a vertical pressure roller 6, and the end of the vertical pressure roller 6 is fixed with an arc-shaped detection plate.

[0018] A control method for automatically adjusting copper strip pickling lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com