Method and device for continuous acid pickling purification of quartz sand

A technology of quartz sand and pickling, which is applied in the direction of silicon dioxide and silicon oxide, can solve the problems of simple and backward equipment, low production efficiency, and difficulty in quartz sand, and achieve continuous pickling purification improvement, improvement of effect, and improvement of quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

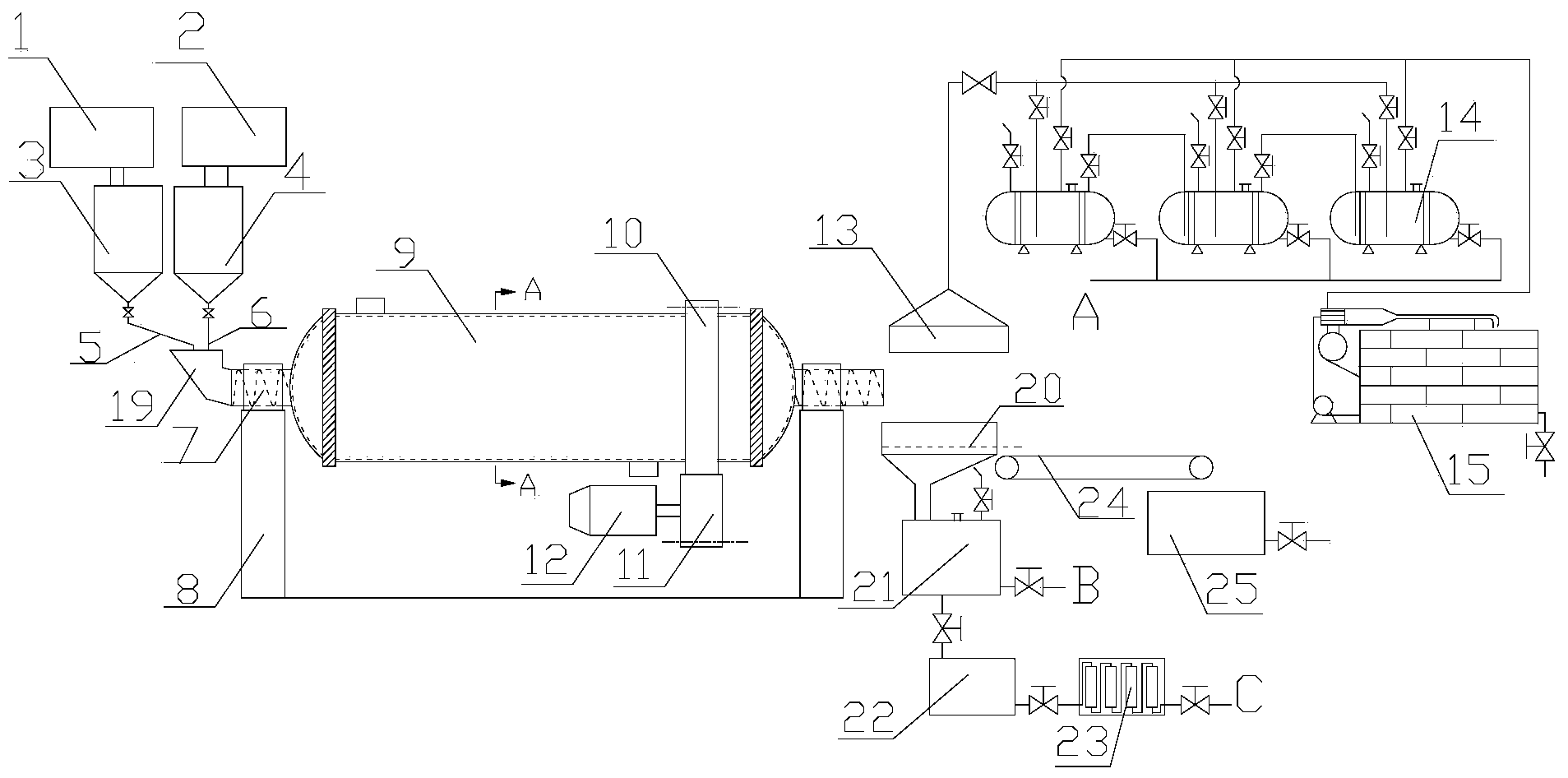

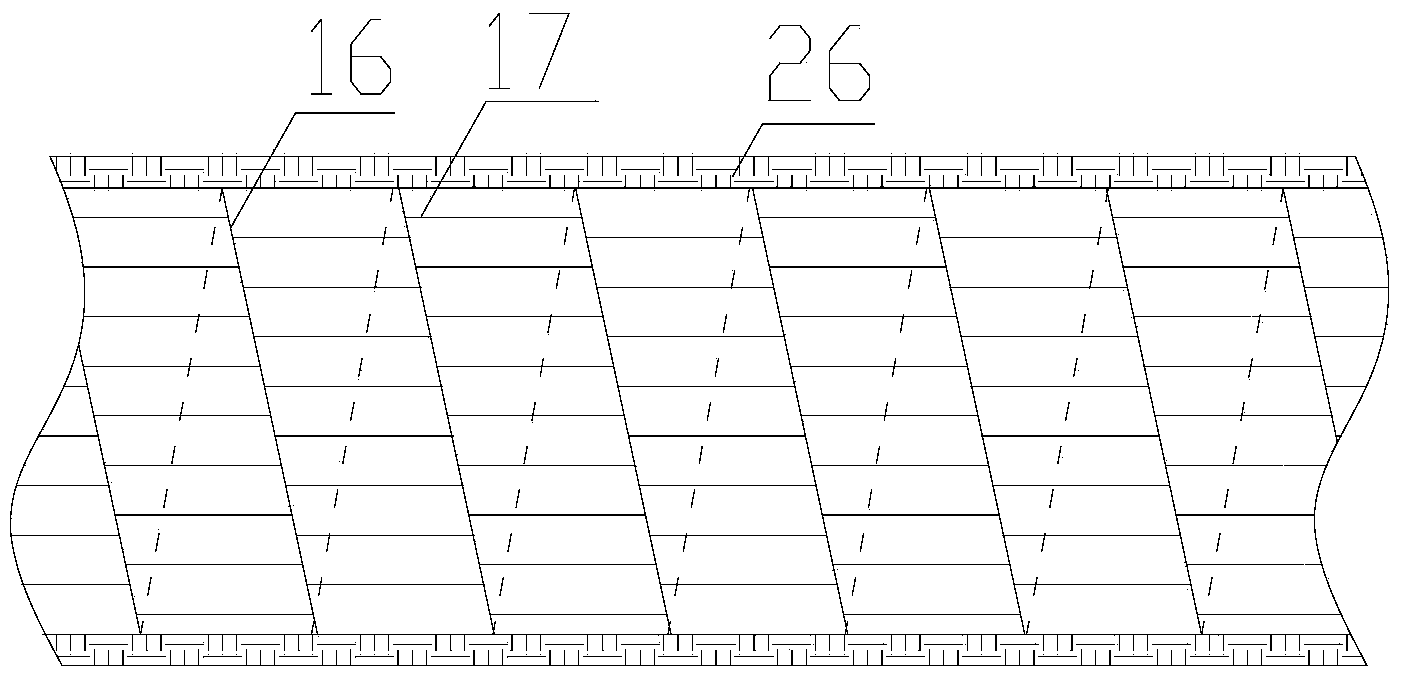

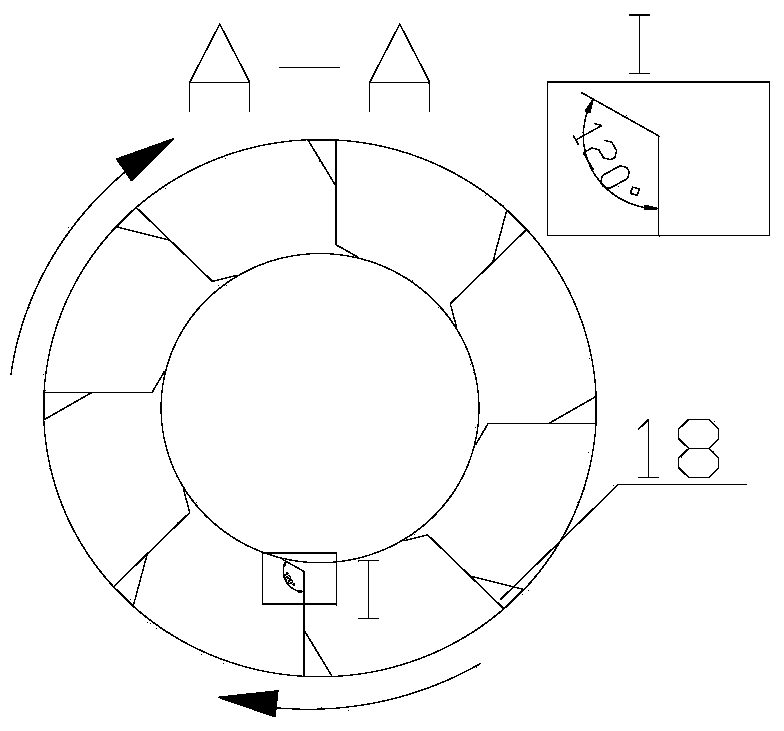

[0030] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0031] The acid solution in this embodiment is hydrochloric acid.

[0032]The concrete steps of a kind of quartz sand continuous pickling purification method are as follows:

[0033] (1) Raw material heating: heat the quartz sand to a temperature not higher than 180°C, and use the authorized utility model patent (patent number: 200620163898.5) to heat the quartz sand heater in a high-purity quartz sand drying device. The final quartz sand is stored in a steel storage tank with a polytetrafluoroethylene lining, and the hydrochloric acid is used at room temperature; or both the quartz sand and the hydrochloric acid are heated to 80-100°C, and the heating method of the quartz sand is the same as above (or the quartz sand is heated by electric heating) The method of heating the glass tube by baking sand), the heating method of hydrochloric acid uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com