Automatic feeding machine for lighters

An automatic feeding and lighter technology, which is applied in the field of feeding machines, can solve the problems of high labor intensity and high production costs, and achieve the effect of improving feeding efficiency, reducing costs, and making the feeding process simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

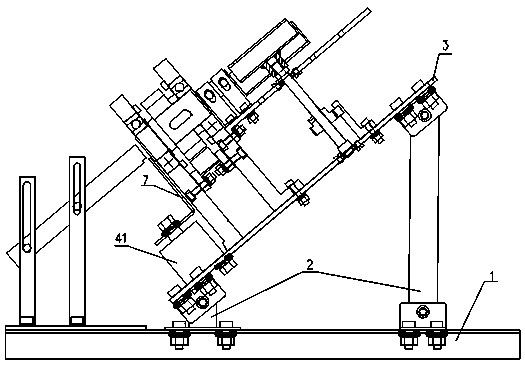

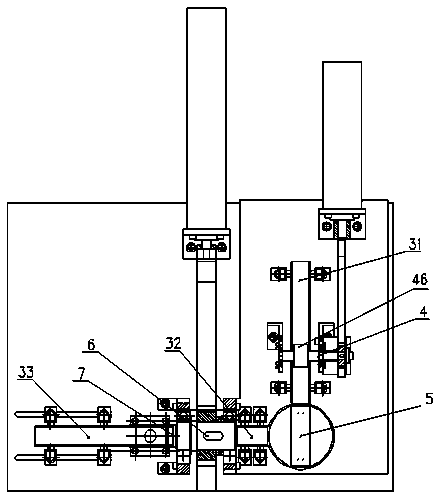

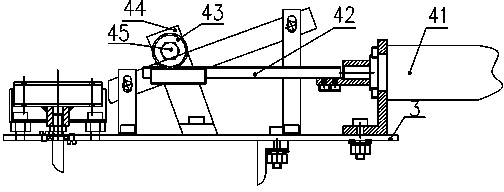

[0021] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-7 As shown, a lighter automatic loading machine includes a base plate 1, a bracket 2 and an inclined base plate 3, the inclined base plate 3 is a 7-shaped track with an angle of 30° with the base plate 1, and the inclined base plate 3 passes through the bracket 2 It is connected with the base plate 1; the inclined base plate 3 includes a loading track section 31, a transition track section 32 and an unloading track section 33, and the inclined base plate 3 is sequentially provided with a discrete mechanism 4 with a cylinder 41, state recognition Mechanism 5, state changing mechanism 6 and baffle plate 7, the discrete mechanism 4 is located at the feeding track section 31, the state identification mechanism 5 is located at the junction of the feeding track section 31 and the transition track section 32, and the state changing mechanism 6 is located at the transition tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com