Interference filter, interference filter manufacturing method, optical module, electronic apparatus, and bonded substrate

An interference filter and manufacturing method technology, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as difficulty in ensuring surface accuracy, air leakage, and inability to fully ensure air tightness, and achieve high air tightness. , the effect of improving the bonding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0092] Hereinafter, a first embodiment according to the present invention will be described with reference to the drawings.

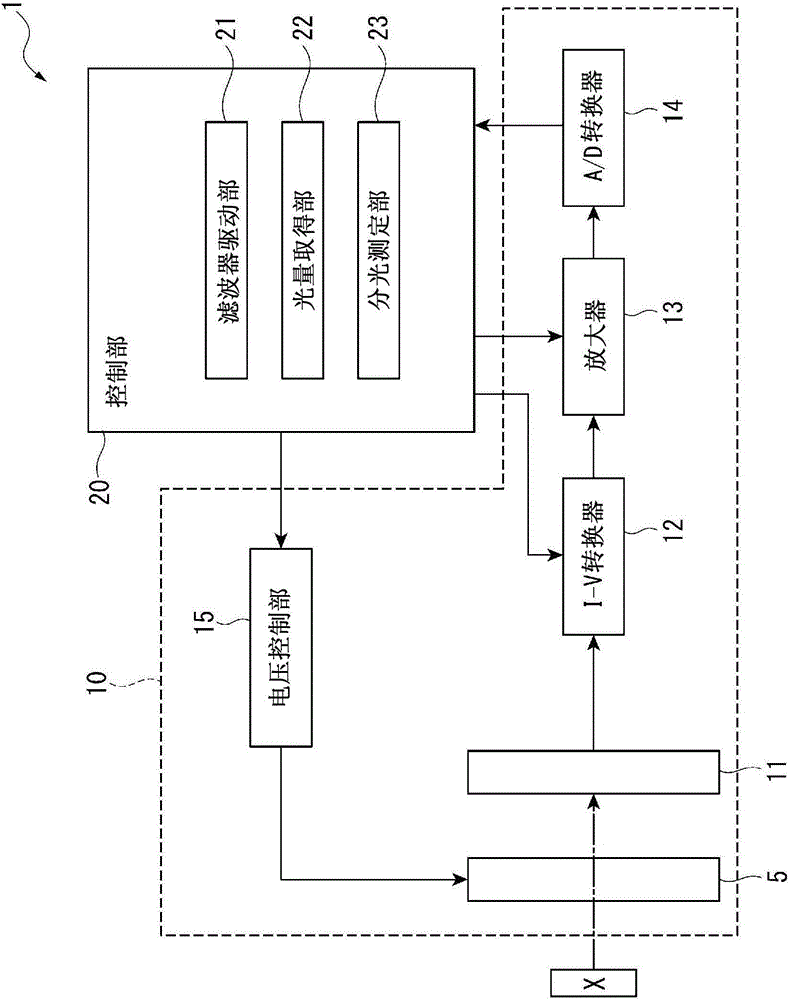

[0093] The structure of the spectrometer

[0094] figure 1 It is a block diagram showing a schematic configuration of the spectrometry device according to the present invention.

[0095]The spectrometer 1 is an example of the electronic device of the present invention, and is a device that analyzes the light intensity of each wavelength of the measurement object light reflected by the measurement object X, and measures a spectral spectrum. In addition, in this embodiment, an example of measuring the measurement object light reflected by the measurement object X is shown. As the measurement object X, for example, when using a luminous body such as a liquid crystal panel, the light emitted by the luminous body can be used as the measurement object Light.

[0096] Next, if figure 1 As shown, this spectrometer 1 includes an optical module 10 and a contr...

no. 2 approach

[0250] Next, a second embodiment according to the present invention will be described with reference to the drawings.

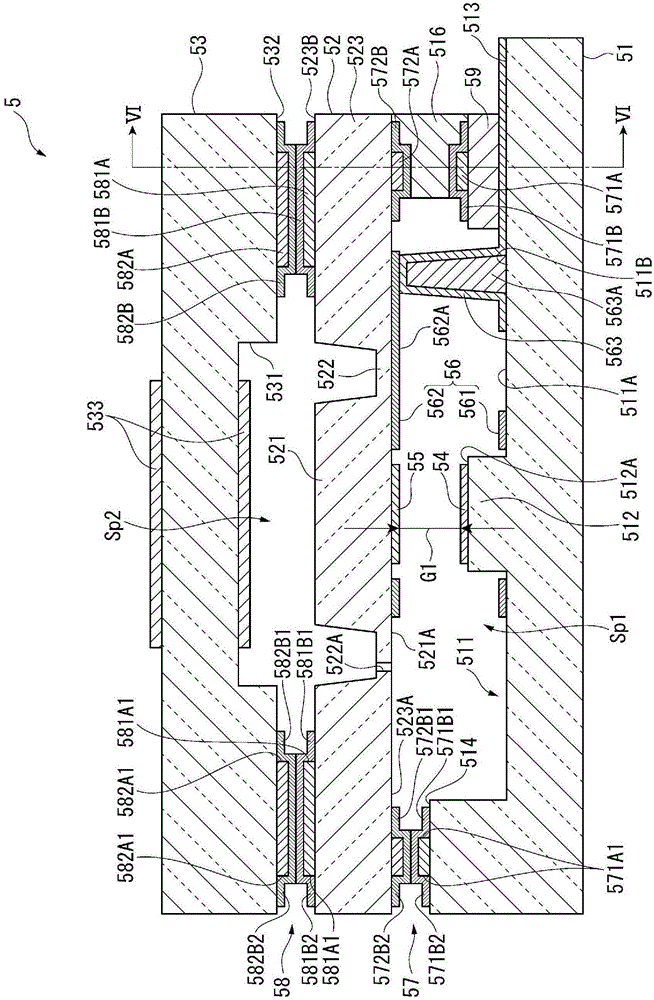

[0251] In the above-mentioned first embodiment, each of the surfaces to be joined 514, 523A, 523B, and 532 is shown as a flat surface, and the resin layers 571A, 572A, 581A, and 582A serving as base layers are formed on these surfaces to be joined 514, 523A, 523B, and 532. example of .

[0252] However, when the resin layers 571A, 572A, 581A, and 582A are formed, the edge 571A1 , 572A1 , 581A1 , and 582A1 may become thicker than other portions due to floating or the like. In this case, portions of the metal layers 571B, 572B, 581B, and 582B formed on the resin layers 571A, 572A, 581A, and 582A corresponding to the edges 571A1, 572A1, 581A1, and 582A1 also float up. Therefore, the metal layer 571B and the metal layer 572B, or the metal layer 581B and the metal layer 582B are in contact only in the floating portion, and the airtightness may not be sufficiently...

Embodiment approach

[0264] In addition, this invention is not limited to the above-mentioned embodiment, The deformation|transformation, improvement, etc. within the range which can achieve the objective of this invention are included in this invention.

[0265] For example, as the resin layer, as mentioned above, it is not limited to the plasma polymerized film, and may be made of other metal structures softer than the epoxy-based photosensitive material and the metal layer (Au). When an epoxy-based photosensitive material is used as the resin layer, since patterning with a photomask is possible, the accuracy of the formation position of the resin layer can be improved.

[0266] Moreover, although the structure which provided the resin layer 571A and the resin layer 572A as a base layer in the 1st junction part 57 is employ|adopted, it is not limited to this.

[0267] As the base layer, it may be provided on either one of the fixed substrate 51 and the movable substrate 52 . Therefore, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com