A subsurface defect detection device and detection method based on AC electromagnetic field

A technology of subsurface defects and alternating electromagnetic fields, applied in the direction of material magnetic variables, etc., can solve problems such as restricting development, failing to meet the comprehensive detection requirements of deep defects in equipment structures, and unable to realize the detection of non-surface defects in workpieces, so as to improve intrinsic safety Level, realize the effect of intelligent identification and quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

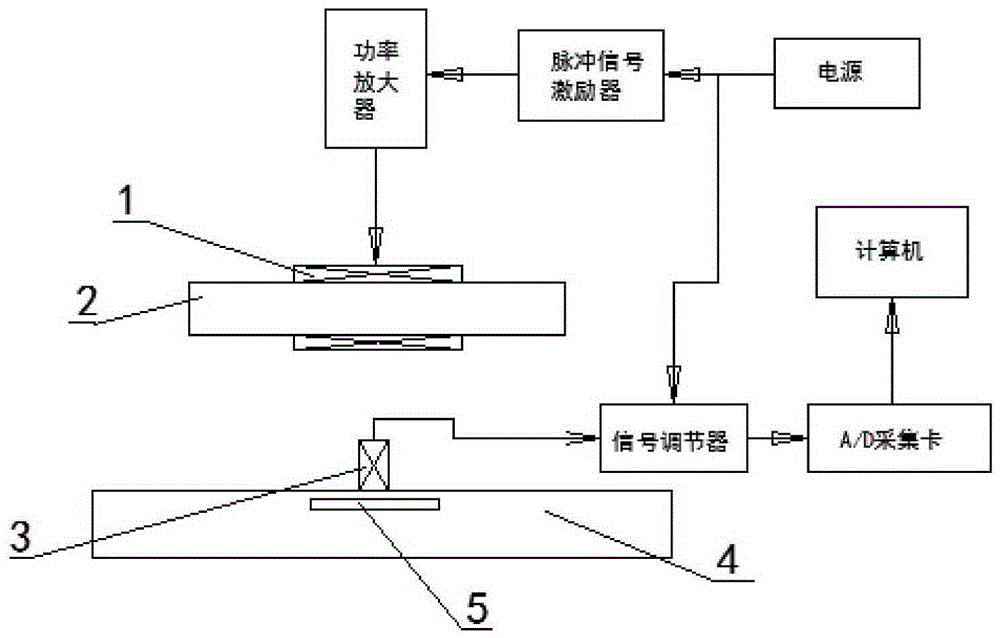

[0019] Such as figure 1 Shown: a subsurface defect detection device based on AC electromagnetic field, including excitation coil 1, magnetic core 2, detection coil 3, signal conditioner, A / D acquisition card, computer, power supply, pulse signal exciter and power amplifier, The detection coil 3 is located below the middle of the magnetic core 2 and is close to the workpiece defect 5 of the workpiece 4. The signal output terminal of the detection coil 3 is connected to the computer through the signal conditioner and the A / D acquisition card in turn, and the power supply is simultaneously connected with the signal conditioner and the pulse. The signal exciter is connected. The signal output end of the pulse signal exciter is connected to the excitation coil 1 through the power amplifier. The excitation coil 1 is located in the middle of the magnetic core 2. The signal conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com