Building water discharge vertical pipe table opening

A technology for building drainage and drainage risers, which is applied to buildings, drainage structures, waterway systems, etc., can solve problems such as suspension of irrigation tests and backflow of drainage risers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

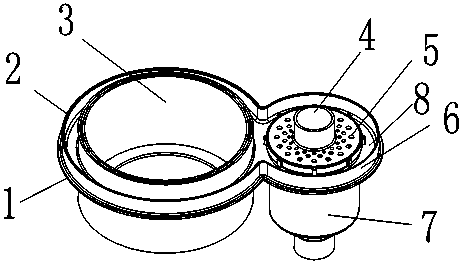

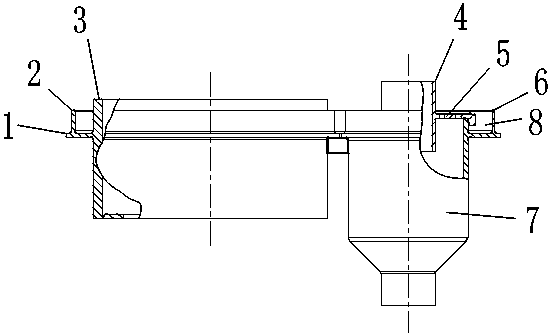

[0018] Such as figure 1 with figure 2 As shown, the drainage standpipe platform includes a casing 3 sleeved on the drainage riser, a pipe fitting 7 for removing accumulated water, a water accumulation grate cover 5, and a waterproof wall 2 surrounding the sleeve pipe 3 and a waterproof wall 6 surrounding the pipe fitting 7.

[0019] The casing 3 and the exterior of the pipe 7 are connected together through a connecting piece 1 , and the waterproof walls 2 and 6 are substantially vertically arranged on the connecting piece 1 .

[0020] The above-mentioned accumulated water grate cover 5 communicates with the internal channel of the pipe fitting 7, and the accumulated water accumulated between the waterproof wall 2, waterproof wall 6, casing 3, and pipe fitting 7 can flow into the pipe fitting 7 through the through hole on the accumulated wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com